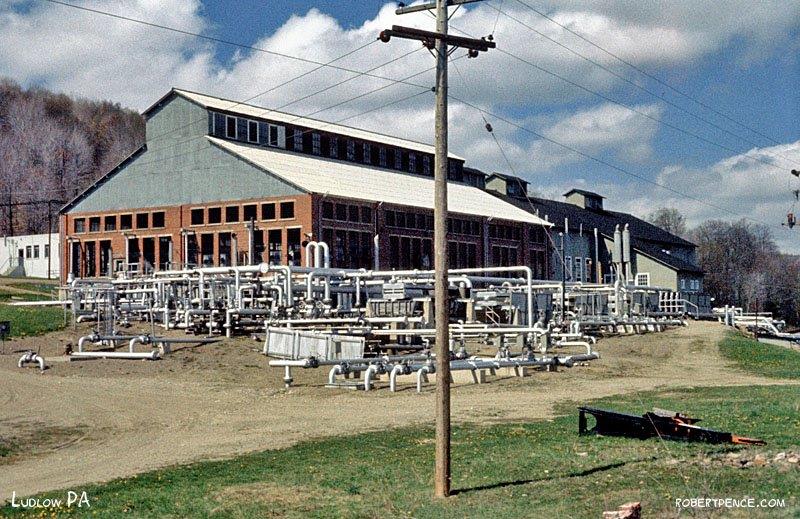

This photo by Robert Pence shows Roystone Station as it appeared in 1963. The station had five Snow engines: two 600 hp engines, two 400 hp engines, and a 750 hp engine. The 750 was an ancient, twin tandem, double-acting unit, serial number 90.

Engine G329, one of the two 600 hp units, at Roystone. Robert Pence captured this photo of the engine in operation in 1963.

Paul Harvey notes that in the 1970s and 1980s it was very pleasant to stop by on a cold winter evening and hear both of them pounding away at full capacity - and probably a little bit more. He and John Wilcox spent many evenings there.

When needed, the engineers would run the units up to 110 rpm. They were very well maintained and never failed when in demand service.

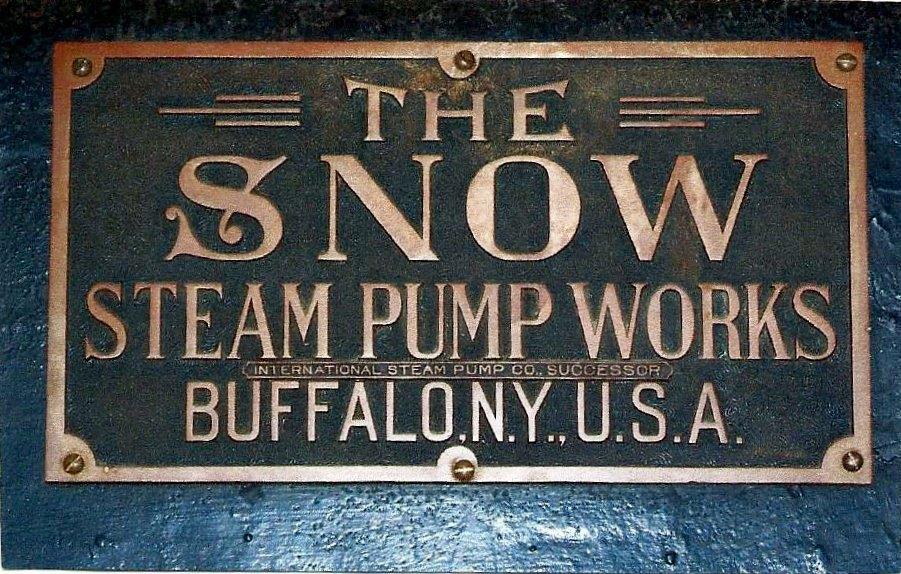

The nameplate from G329 indicates that the engine was built by Worthington, successor company to Snow. The "Size" inscription shows that the power cylinders are 24 inch bore, the compressor cylinder is 18 inch bore, and the stroke of the power and compressor pistons is 48 inches. The "No" inscription shows the serial number G329 and indicates that the engine was built in 1917. (Photo by Loree Paulson)

Earlier Snow engines carried large and elegant nameplates such as this example. They were usually on the side of the main frame and had no individual identification inscriptions. The engine would then also have an identification plate that carried the serial number and size.

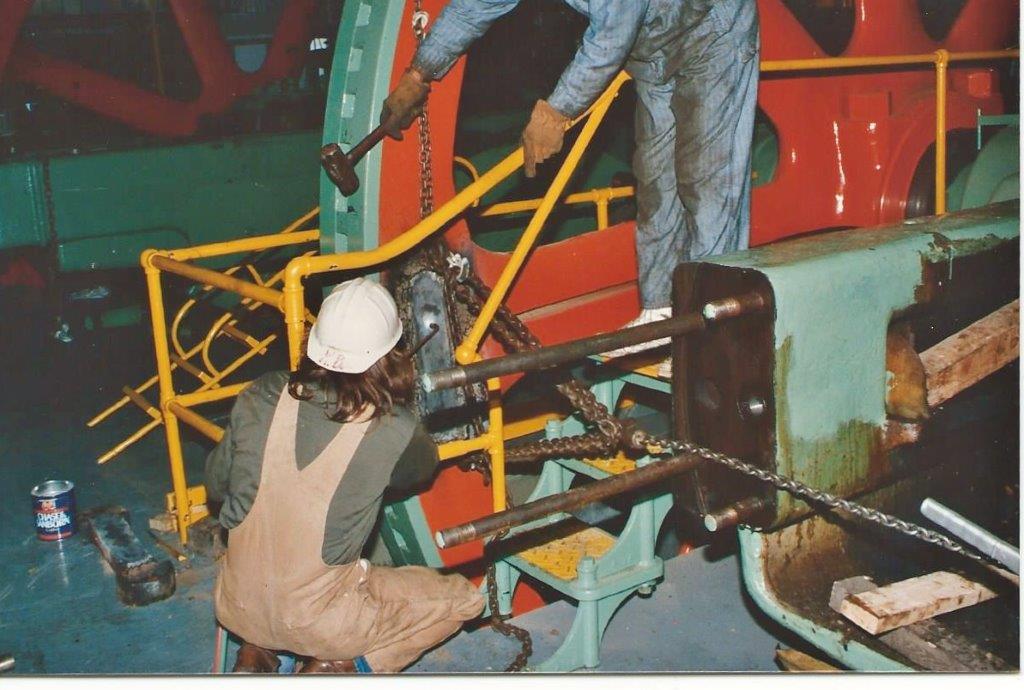

The monumental job of disassembling the engine began in 1993. Simply taking a large machine apart is challenging enough. This machine had to be disassembled in a careful and organized manner so that the parts could be moved, stored, and reassembled at a later date. G329 is on the right in the photo. Its compressor cylinder is hanging from the hoist.

While G329 was being disassembled and removed by the crew from Coolspring, G330, the second 600 hp Snow at the station, was being disassembled and removed by a crew from the Western Minnesota Steam Threshers Reunion of Rollag, Minnesota. The gas company gave the Coolspring and Rollag crews a generous window of time in which to work and the two crews worked side by side much of the time. It was very pleasant borrowing tools and ideas. The crews also had to schedule priorities for use of the building's door opening. The Rollag crew was very professional to work beside. Oh yes, the two crews had to share the one big manual bridge crane!

The halves of the flywheel are held together with four bolts at the hub and four "dogbone keys" at the rim. One of the keys is on the floor in the left of the photo, next to the coffee can. During engine assembly, the keys were heated and installed in pockets at the joint of the flywheel. As the keys cooled, they contracted and pulled the flywheel halves firmly together.

The keys had to be removed to permit disassembly of the flywheel. The spaces around the keys were filled with concrete grout during the original installation. Grout had to be chipped out to give access to the keys. Removing the keys was then an exercise in heating and "persuasion." The keys were heated until almost glowing red to expand them enough that they could be pulled out.