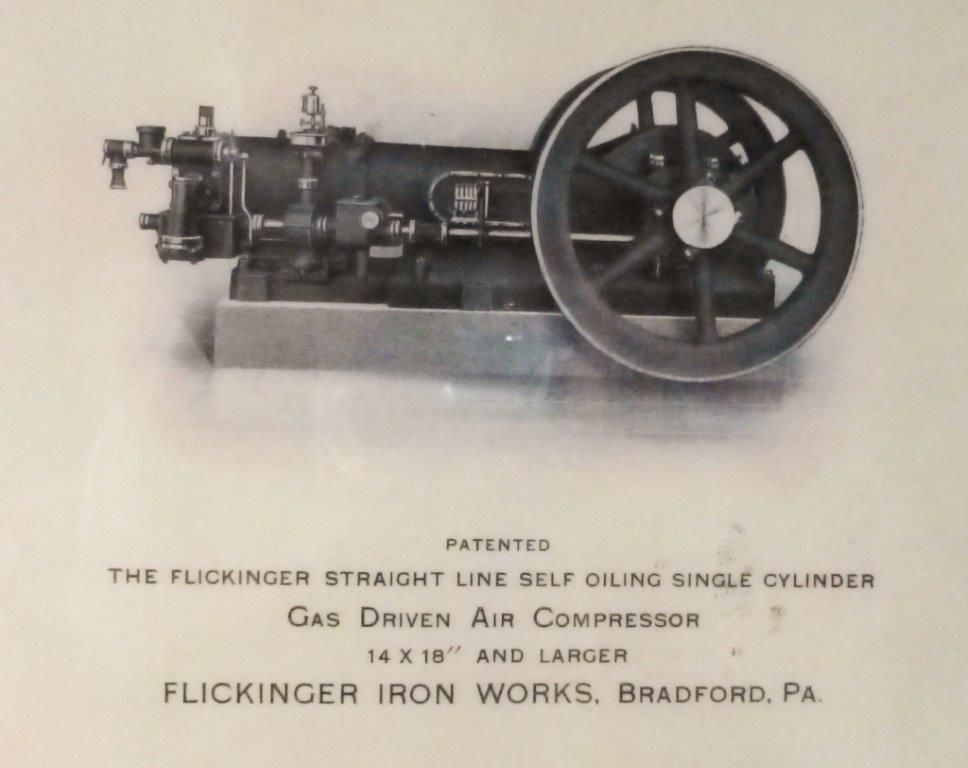

Filling the place of the second 65 hp Blaisdell is a 50

hp Flickinger compressor engine. It was made by the Flickinger Iron

Works in

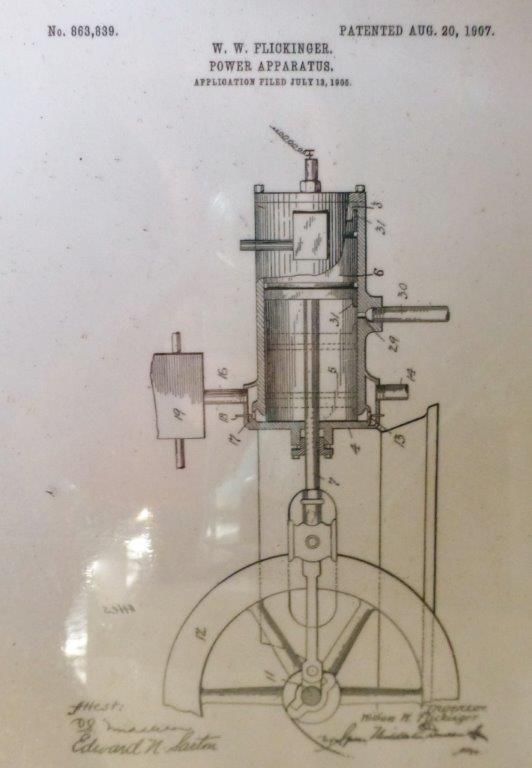

In 1907, William W. Flickinger was granted U.S. patent number 863,839 for a "Power Apparatus." The patent makes reference to an engine that produces power from the crankshaft to drive nearby machinery and also compresses air that may be used to power equipment at nearby or remote locations. It specifically mentions operating oil field equipment using compressed air.

Putting the patent to work, Flickinger offered compressor engines in a number of sizes, including large machines such as the one in this advertisement.

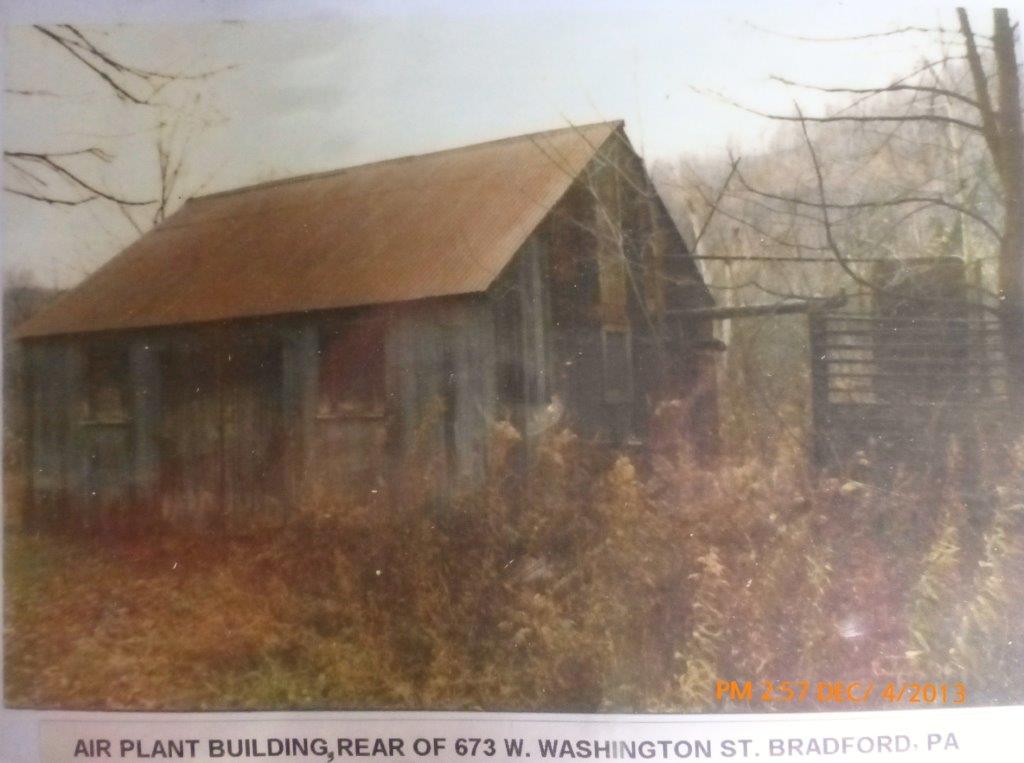

The engine on display at the museum originally occupied this building, located just west of the city of Bradford, Pennsylvania.