Here is a photo of the Windy City building in 1989 shortly after the last run of the air compressing plant. It looked a bit tired at this point in time but good things were about to happen.

Following the retirement of the Blaisdell compressor

engines in 1989, Pennzoil Corporation donated the

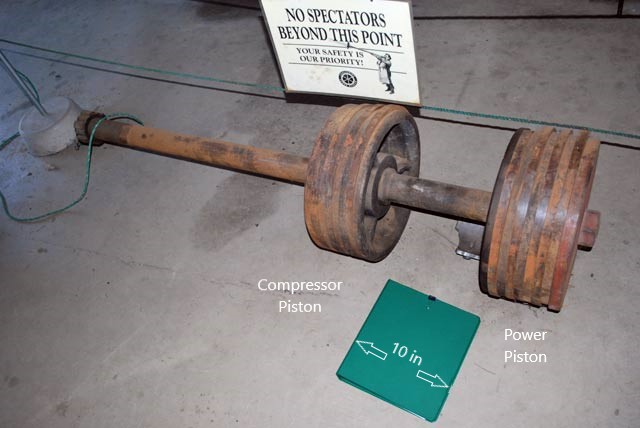

Coolspring Power Museum reconstructed the Windy City building and installed the 65 hp Blaisdell compressor engine along with its auxiliary equipment. Now in its new home in Coolspring, museum engineers continue Jim's work of running and caring for the Blaisdell engine. The photo shows the bolted cylinder head to the right and in the foreground. Combustion occurs at this end of the cylinder. Air compression occurs at the end of the cylinder facing the flywheels. The flywheels are seven feet in diameter and the whole engine weighs approximately 14 tons.

Experiencing the engine while it is running is one of the great benefits of the "living history" nature of the museum, something that a static display can never provide. When idling, the Blaisdell produces a steady, contented, "once every revolution" rhythm from the air compressor with a metallic "thunk" sound from the cylinder at each intermittent "hit" of a power cycle. Each hit is accompanied by a loud report from the exhaust pit near the building. When the engines were compressing air at Windy City it is said that they could be heard at a distance of up to about four miles.

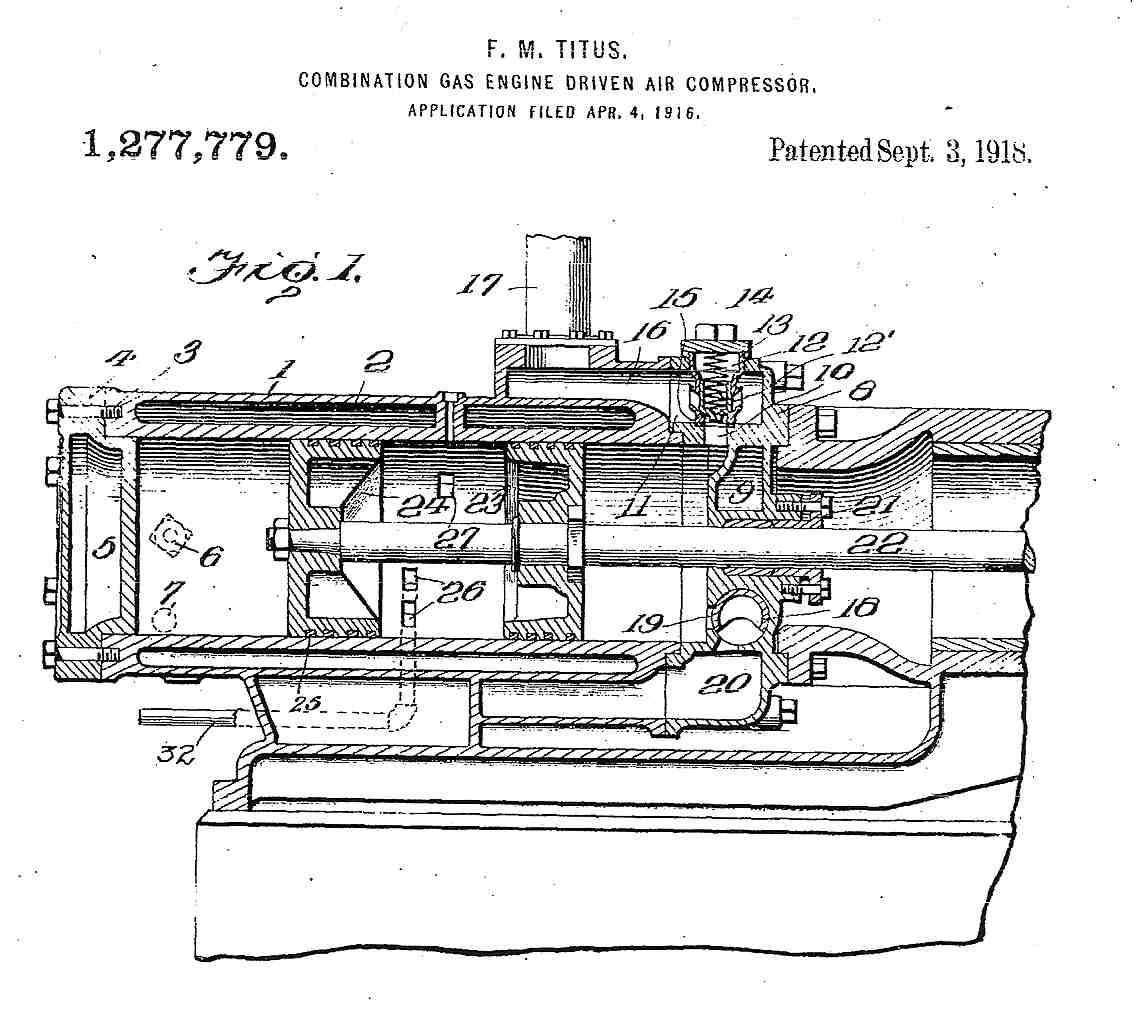

The drawing above is from one of several patents related to Blaisdellís compressor engines. This excerpt from U.S. patent number 1,277,779 describes the "Combination Gas Engine Driven Air Compressor" which forms the basic design for the Blaisdell compressor engine. The patent drawing shows the dual-piston arrangement within the cylinder. Combustion occurs at the left end of the cylinder in this drawing. Air compression occurs at the right end of the cylinder. Note the stuffing box 21 that seals piston rod 22 to hold compressed air in the cylinder. Air compressed by the piston exits the cylinder via spring loaded valves 14 which prevent compressed air in the discharge line from flowing back into the cylinder. The piston rod joins a crosshead (not shown in this drawing) to which the engineís connecting rod is attached.

U.S. patent number 1,209,077, "Operating Means for Compressor-Valves" details the cam-and-pushrod mechanism which operates the air compressorís Corliss-style rotary inlet valve. In addition, U.S. patent number 1,348,604, "Pressure Throttle Control" describes the air pressure operated valve that controls gas admission to the engine. This valve is intended to regulate engine speed by restricting fuel input once the pressure of the air in the compressorís discharge line reaches a desired maximum value.

Itís interesting to note that Philo Blaisdellís son, George Grant Blaisdell, sold Blaisdell Machinery Company in 1920 and went on to found the Zippo Manufacturing Company, which still produces the world-famous Zippo lighters in Bradford, Pennsylvania.

This photo shows the museum's spare piston assembly for the Blaisdell. Compare it to the patent drawing, above. The green three-ring binder on the floor next to the assembly provides a sense of scale. Given the engine's 16-inch bore, the binder would easily fit into the cylinder! Combine the 16-inch bore with a 20-inch stroke and the combustion engine has just over 4000 cubic inches (66 liters) displacement...in one cylinder.