Air piping from the compressors ran along the ground in a pair of loops. The loops acted as aftercoolers for the compressors to reduce the temperature of the compressed air and to remove moisture from the air.

This photo gives an overview of the site of the air compressing plant. The cooling water storage tank for the engines is visible at the right of the photo. It was kept full from a spring on the hill and the water was "wasted" through the engines into the little stream which also forms the exhaust pit. The tank was always full and just overflowed into the stream.

Shown here is one of the steam engine and pump jack

installations at a

Jim McCauley began working in the

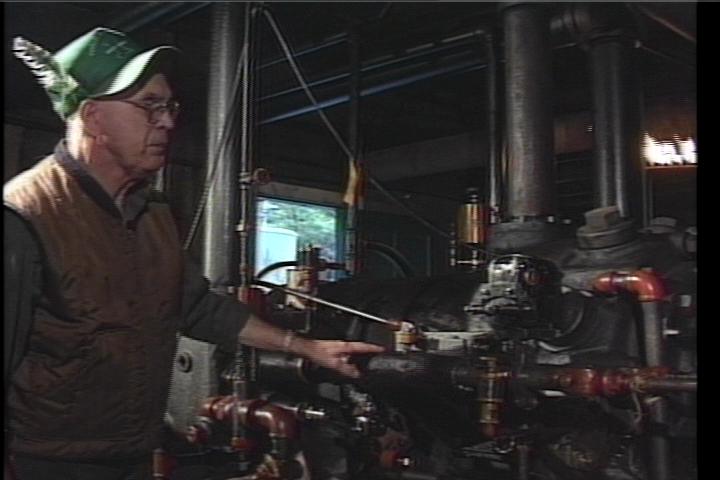

The photo shows Jim McCauley describing the features of

the Blaisdell compressor engine on its last day of operation,