April 2013

Smoke in the Valley

By Paul Harvey

It is now April and hopefully the winter is behind us.

With spring here, it means the awakening of

Our featured group of engines for this year will be "Oil

Engines" and by this we mean any engine that uses compression ignition.

This group also injects or takes in a fuel that is heavier than gasoline

or natural gas and is sprayed into the cylinder. The heat of

compression then causes the explosion or power stroke of the engine.

Hence the name of "Oil Engines."

Oil engines have one thing in common and that is they usually produce a lot of smoke when they run. Most everyone can recall seeing an older diesel truck bellowing out clouds of black smoke when working hard on the hills. So as our year unfolds, we anticipate producing a lot of smoke in the valley. This issue will discuss some of the various types of oil engines that reside at our museum.

Before proceeding to the various types, we shall take a closer look at how these engines operate and how they differ from gas engines. They can be either two-cycle or four-cycle but the basic principles are the same. Gas engines, such as in your car or lawn mower, use a gaseous fuel; either vaporizing gasoline or using natural gas or propane. They are typically lower in compression and require an external source of ignition; either spark plug, make-and-break ignitor, or hot tube. On the other hand, oil engines use a heavier liquid fuel such as kerosene, diesel, or crude oil and have a higher compression. As the compression rises on the combustion stroke of the engine the air in the cylinder is heated. At a predetermined time, the oil is sprayed into the cylinder and the heated air causes combustion and produces the power stroke of the engine. Some require a pre-heating device to get started, such as a glow plug in a modern diesel, but all use the heat of compression to operate.

The first group to be discussed are the Hvid

injection oil engines. These were built by many different manufacturers

in the

The second group to be considered are the "hot

start" four-cycle oil engines. These engines require heating a bulb or

plate with an external torch to start and then will run without the

external heat when operating under load. The first "hot start" oil

engine actually preceded the Diesel and was produced in 1894 by Herbert

Akroyd Stuart in

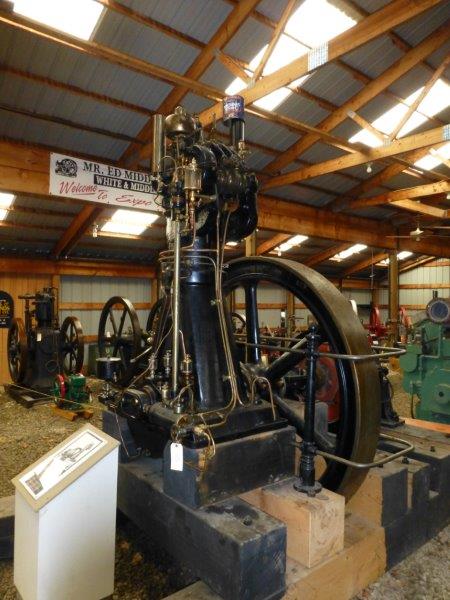

The third class are the true Diesels as designed

by Dr. Rudolph Diesel of

The fourth category is the "modern diesels."

These are engines that evolved from Dr. Diesel's design but are

significantly different in that they directly inject the fuel from a

high pressure liquid fuel pump and do not use the compressed air blast.

The true Diesels described in class three use a capital "D" on Diesel,

but these evolved engines are not capitalized. Hence a big truck has a

diesel engine and not a Diesel. Photo 10 shows a 12

horsepower Witte diesel light plant made in the 1930s. These are great

running engines using a high pressure liquid pump to inject the fuel.

Witte was made in

The fifth class is the hot start two-cycle oil

engines. They all had a device on the head that needed external heat to

start but not to run. During their evolution, the heating device became

smaller and the engines became more efficient. The museum's Mietz and

Weiss oil engine, built in

It is hoped that the reader has enjoyed this brief tour into the world of Oil Engines. The author chose the five classes listed above for simplification in this article. However, the array of oil engine designs is almost endless. Some were built in large numbers while others probably never left the drawing boards. It will be interesting to view what our Exhibitors bring for the June Show!

The museum will be open for the first time in

2013 on April 20 and 21. Only select items will be running as the

cooling water system will not be filled until May. However, we

will enjoy conducting a personal tour for you. Our event dates for

2013 will be:

Open Weekend

April 20 & 21

Open Weekend

May 18 & 19

June Show

June 13, 14, & 15

History Day & Truck Show

July 20

Open Weekend

July 20 & 21

Open Weekend

August 17 & 18

Open Weekend

September 21 & 22

Fall Show

October 17, 18, & 19

Just a reminder that the back issues of The Flywheel are available from the links to the left. Also, be sure to visit our Publications page to find literature for sale. This portion of our site will continue to grow.

We are looking forward to a wonderful but smoky season. Hope you can attend! See you then!

Photo 1: 7 hp Thermoil Type U engine

Photo 2: 9 hp Thermoil Type U engine

Photo 3: 9 hp Parmaco engine

Photo 4: 4 hp St. Marys HO engine

Photo 5: 30 hp St. Marys Hvid engine

Photo 6: 35 hp Hornsby-Akroyd engine

Photo 7: 65 hp DeLaVergne DH engine

Photo 8: 9 hp Blackstone Oil Engine

Photo 9: 12 hp Augsburg Diesel engine

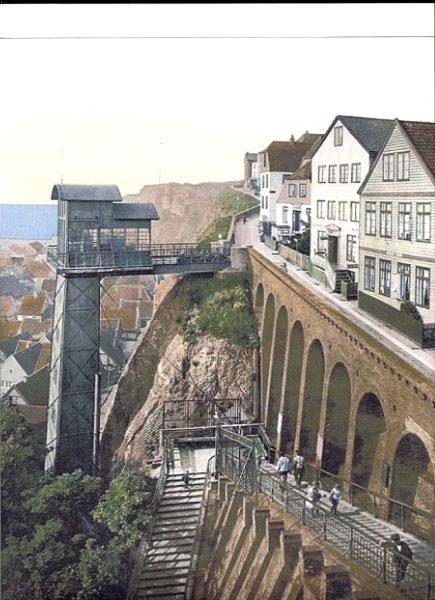

Photo 9a: The lift at Helgoland

Photo 9b: Illustration of Helgoland

Public Domain image from Wikimedia Commons

Photo 10: 12 hp Witte Dieselectric engine and generator set

Photo 11: 50 hp Otto diesel engine

Photo 12: 8 hp Benz diesel engine

Photo 13: 6 hp Mietz and Weiss engine

Photo 14: 45 hp Primm engine

Photo 15: 25 hp Kahlenberg engine