Diesel Centrale CPM Exhibit

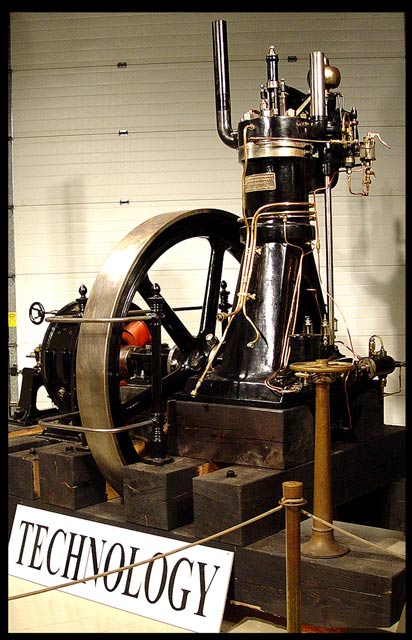

The Coolspring Power Museum volunteers are embarking on a very exciting project to restore our Augsburg air-blast diesel engine to operation and to provide an appropriate display area for it. It will be the oldest operating diesel engine in existence. Diesel Centrale CPM, our new display area, will be the home to the Augsburg engine and several other historic diesel engines.

We need your support to complete this important project.

The Augsburg is a diesel engine in that it uses air heated by compression in the cylinder to ignite fuel injected directly into the cylinder. Modern diesel engines use "solid injection" where liquid fuel is directly pressurized and sprayed into the cylinder. Before the successful development of solid injection, the Augsburg and early engines like it used high-pressure air to inject and atomize the fuel. This class of engines became known as "air-blast injection" engines.

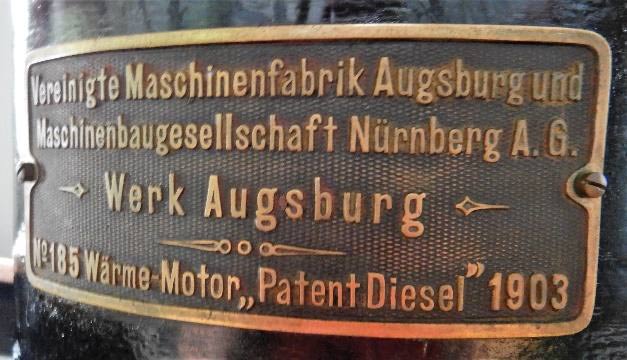

The Augsburg air-blast diesel engine is serial number 185 and was built in Augsburg, Germany, in 1903. It was sold to Siemens and Halske of Hamburg, Germany, to be fitted with a direct current generator. Please read our detailed description of the engine for additional information.

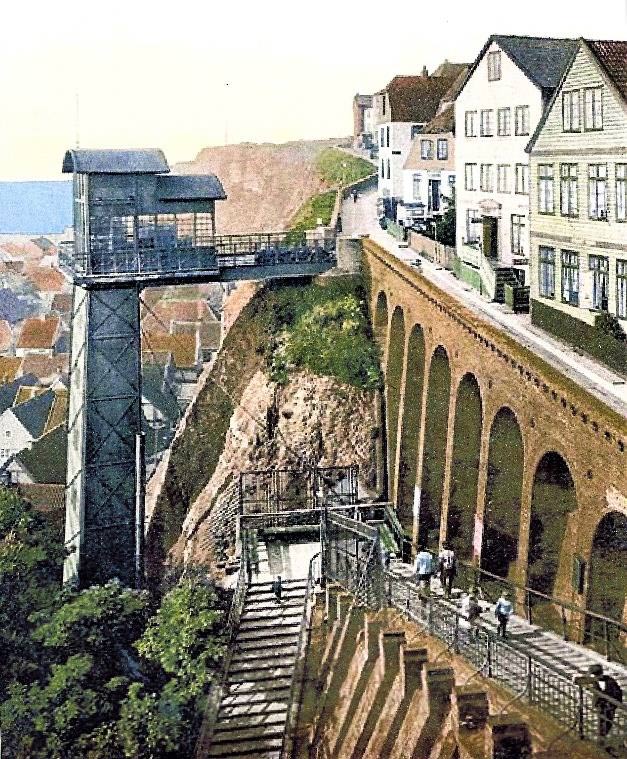

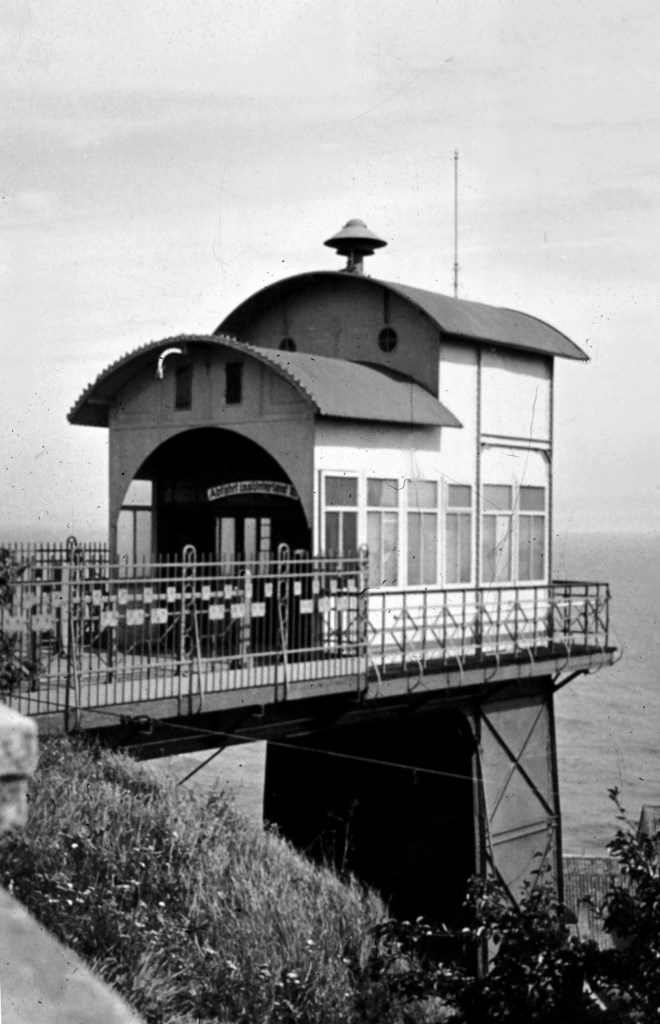

On March 16,1903, it was shipped to the North Sea island of Helgoland where it powered a lift, or elevator, to take passengers from the southeast coastal plain and beach to the higher central part of the island.

The height of this lift was 50 meters. In the photo on the left note the staircase for scale. The Augsburg and its generator were housed in a building at the base of the lift. It served faithfully until 1928, when Henry Ford purchased it for his museum in Dearborn, Michigan.

It was fortunate that the engine and generator found a new home in Michigan. During World War II, Helgoland was the target of an intense bombing campaign by the British Royal Air Force in April 1945. The lift and much of the surrounding infrastructure were badly damaged or destroyed.

The Augsburg was proudly displayed at the Henry Ford Museum for many years until it was de-accessioned by the museum. It went through several collections, including a period at the Owls Head Transportation Museum in Rockland, Maine. Then a benevolent donor placed it at Coolspring Power Museum.

Our goal is to bring this historic engine back

to running condition for the education and enjoyment of our visitors.

In addition refurbishing the engine, we will be constructing a “period

correct" building to house this engine. The drawing above shows a concept for the

building. In fact, there will be two additional museum-owned

engines added later as expansions to the air-blast injection engine

exhibit continue.

You can participate in the funding of this project in several ways with your tax-deductible donation! Please consider making a financial contribution to support the Augsburg project. Visit our Contribute page for more information on financial contributions and to obtain a copy of our Contribution form.

We offer the option to contribute to the Augsburg engine project via PayPal. Click the Donate button below to begin your donation transaction.

Help make our Augsburg diesel run by purchasing photos related to this engine. Proceeds from sales of the photos support the Augsburg engine project. Please see our Augsburg Photos page for further details.

We thank you for your generous contribution. Please support and follow this exciting project as it develops!

Diesel Centrale CPM Progress Reports

Progress Report - November 2020

The Augsburg/ABI project is moving forward after the preliminary

work has been completed. The site selected for the building will

be just north of the water tower on the hill near our Pat's Place and

Exley Station exhibits. This location will afford a pleasant

approach. The plans and building design are coming along nicely.

The building will take on the appearance of a German power house from the turn of the 20th century. Architectural details will include wide eaves, a gable roof with composite tiles to mimic the German terra cotta tile, large swing doors with big hinges, and arched windows that are narrow and tall. The interior will feature a period ceramic tile floor with a wainscot wall area of tile behind the engines, just as a power house should have. Of course, the building will include brick pavers with the inscriptions of donors, present and future. The exterior is to be brick while the interior is post and beam construction.

The foundation drawings have been submitted to the contractor awaiting insertion in their schedule.

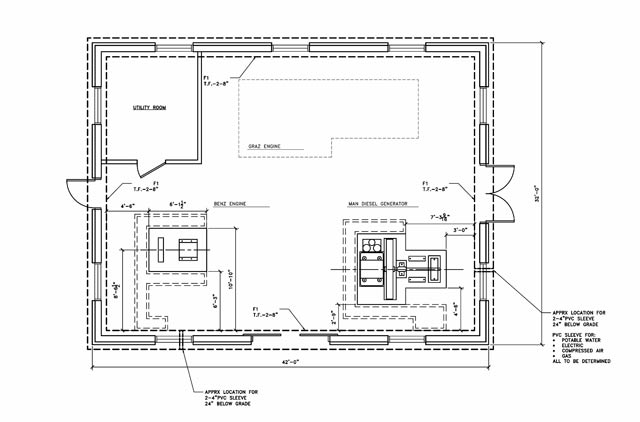

When the building is complete, we will have an exciting, world-class power house exhibit. It will first house our Augsburg air-blast engine. Next year we will receive a Graz air-blast engine to include in the exhibit. Finally, we will add a Benz engine. Together, these three engines will represent twenty years of Diesel evolution.

The museum is offering for sale a professionally-produced photograph of our Augsburg engine at Coolspring Power Museum. The photograph is available on our Augsburg Photos page. Please join us in our enthusiasm for this project, support the project, and follow our progress!

Progress Report - December 2020

We listed the architectural details of the Augsburg/ABI building in November 2020 report. Our goal is to have the building resemble the appearance of a German power house from the turn of the 20th century.

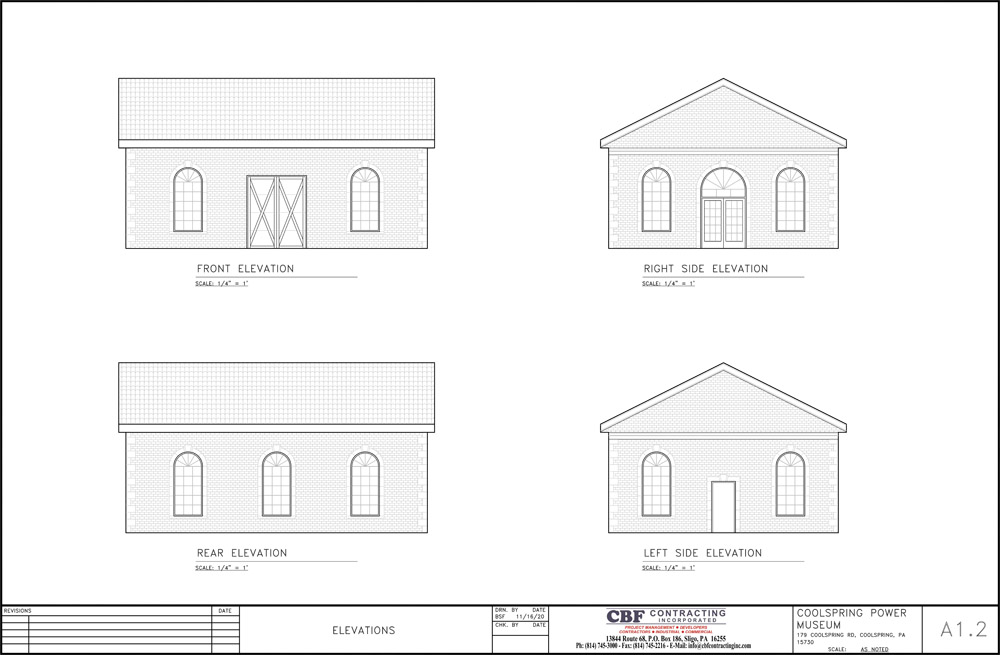

Here is the latest set of elevation views of the building.

The photo above shows what we will be trying to achieve with the post and beam construction, roof trusses, and roof decking. At this point in time we are working to finalize details of the building design before moving on to foundation work.

Progress Report - March 2021

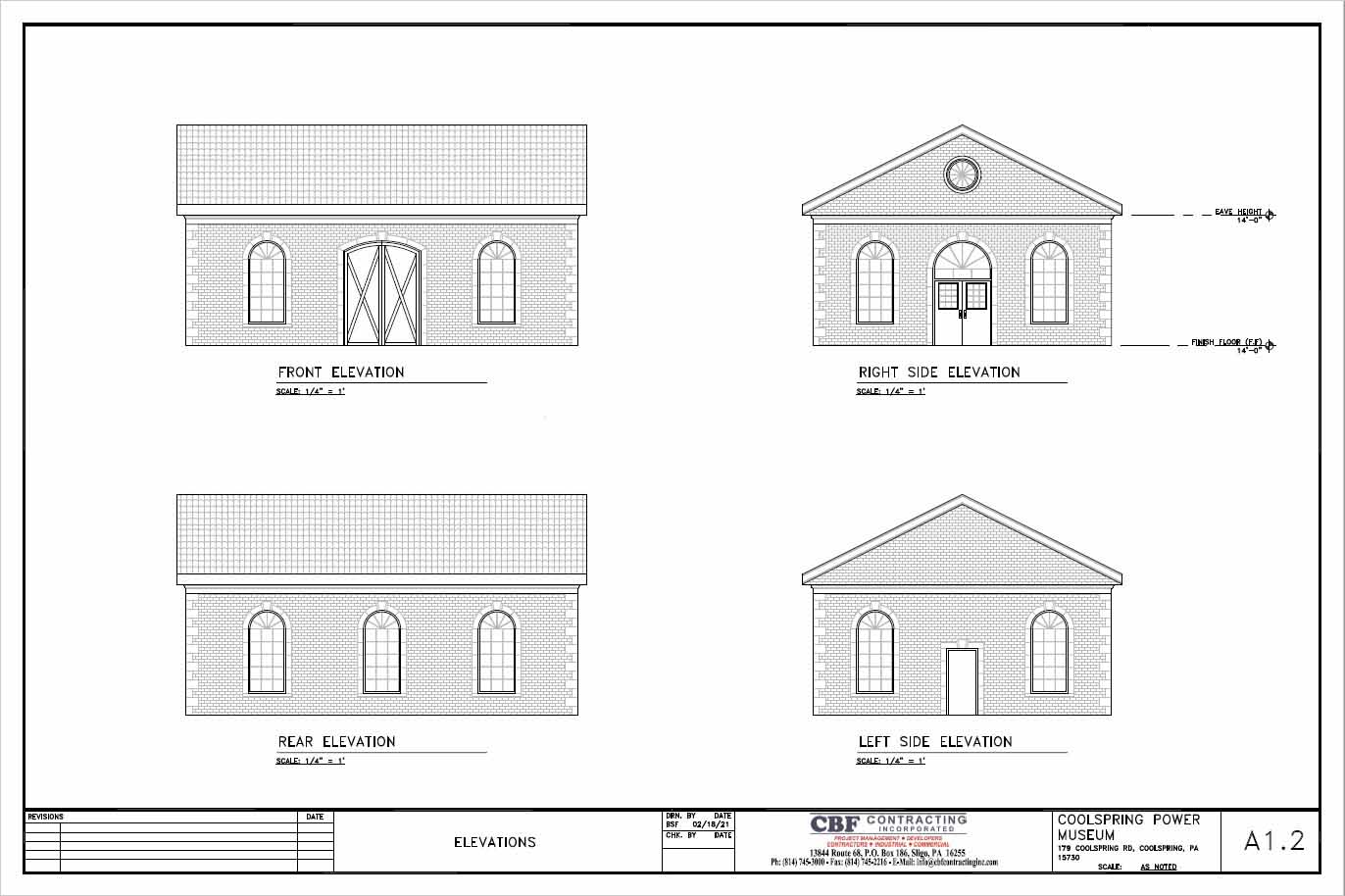

Planning work for the building continues. Our architect refined the details of the building and produced these new drawings.

Note revisions to the front and right-side doors. Also, a round window now adds a touch of visual interest to the right-side gable. It should also introduce some light to the post and beam roof trusses.

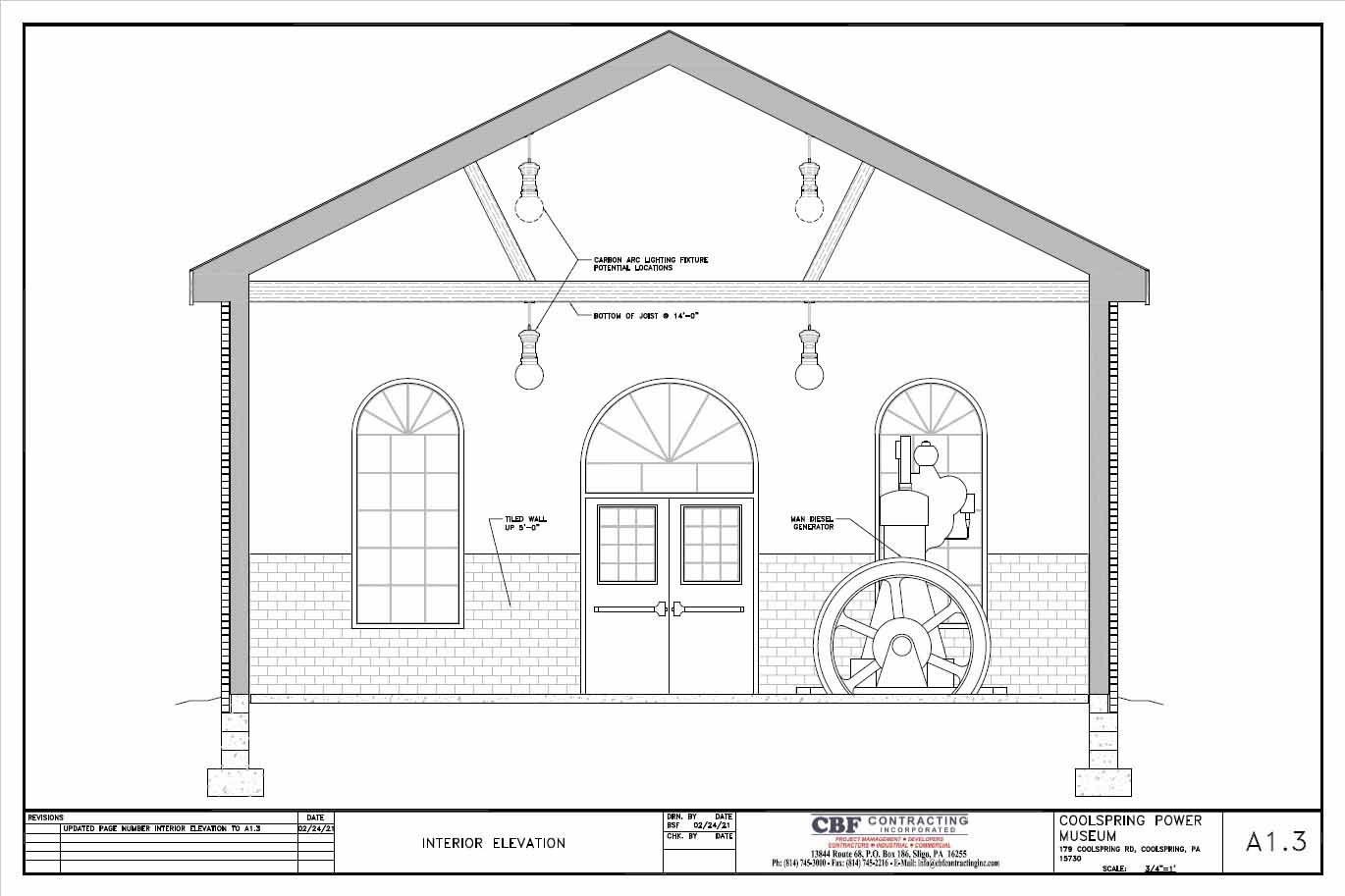

Details of the interior also received attention. This view shows the placement of the engine, details of the tile wall treatment, and concepts for installation of lighting fixtures.

Progress Report - April 2021

Be sure to read the April 2021 edition of The Flywheel, our online history series. Paul Harvey tells the story of the museum's Benz Type R engine that will be located in the Augsburg/ABI building.

Progress Report - May 2021

In the May 2021 edition of The Flywheel, Paul Harvey provides an update on the site preparations and design work for the Augsburg/ABI building.

Progress Report - June 2021

Take a trip to Germany in the June 2021 edition of The Flywheel. Paul Harvey tells the story of the historic Graz engine that will be part of our air-blast injection engine exhibit.

Progress Report - August 2021

The dream is becoming a reality. Construction of the Augsburg/ABI building has begun! In the August 2021 edition of The Flywheel, Paul Harvey provides an update on the status of the building project.

Progress Report - September 2021

A 1,250 gallon sump tank has been buried. It will collect the engine cooling water to be recirculated to an overhead tank.

The Graz foundation has been poured. It required 26 1/2 yards of concrete.

These four concrete columns will support a 1,000 gallon overhead tank for cooling water.

The foundation cleaned up and ready for the upcoming work. Fourteen inches of top soil and debris have been removed, and now the floor work begins.

Progress Report - October 2021

The building will have underfloor heating. All the hydronic heating tubing is in place and tested. Now the contractor is awaiting a nice day day to pour the floor. Also, note in the background that the tank for engine cooling water is installed on the concrete columns.

Progress Report - December 2021

Our contractor poured the concrete floor for the building on November 24, 2021. To prevent winter damage, the concrete block wall was filled with concrete. With those tasks done, the area around the building is being back graded.

To the right, this photo also shows the overhead cooling water tank for the building.

Progress Report - January 2022

The ABI Building project now has an official name: Diesel Centrale CPM

This name is inspired by the Diesel Centrale powerhouse in Austria that holds several Graz engines. Diesel Centrale provided electricity for the surrounding industry and operated from the early 1900s until the 1950s. It remains intact.

The floor and foundation for the Diesel Centrale CPM building are now covered and prepared for the winter. Construction activities will resume in the spring.

Progress Report - July 2022

This month the focus of the project shifted to the city of Hof in the Bavarian region of Germany. Mike Murphy, Tom Stockton, and Jonah Close of CPM traveled to Hof to work with Dr. Friedrich Busch and several local engine collectors to document, disassemble, and pack the Graz engine for shipment to Coolspring. Following a final run of the Graz, the crew went to work.

Dr. Busch and the Graz as disassembly begins. Local engine collectors also assisted, shown here working on the top end of the engine.

The lower end of the engine shows the beautiful machine work on the parts as well as the excellent condition of the engine. Removing the cylinder from the engine was just one of the delicate, heavy lifts required for the disassembly and packing operation.

With the cylinder moved aside, the engine base and crankshaft were exposed. Initial packing involved strapping large components to pallets.

The cylinder head and camshaft now on a pallet. A flywheel half was another heavy lift. The forklift proved to be handy for this work.

With most of the engine components boxed or on pallets, it became apparent just how many parts make up the Graz engine. The shipment occupied much of the floor of the truck. After final packaging, the Graz engine will be on its way to its new home in Diesel Centrale CPM.

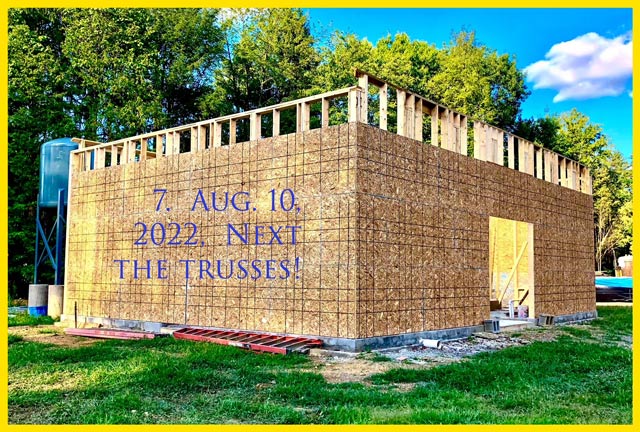

Progress Report - August 2022

Back in Coolspring, our construction crew has been busy! The walls of the Diesel Centrale CPM building are now up. The next step will be to add roof trusses.

Speaking of roof trusses... The first two trusses for the building arrived on site. Paul Harvey's classic International West Coaster expedited the delivery.

Progress Report - September 2022

Thanks to Stewart McKinley and Paul's West Coaster, all eight roof trusses are now on site.

The trusses are fabricated steel with wood attached to them to carry the roof panels.

The building is taking it final form with the trusses in place and roofing materials being installed. The roof system should be sturdy and will give the interior of the building an interesting, industrial ambience.

At last, the building has a complete, waterproof roof. The roof system gives a clear span with plenty of free height beneath.

Although they resemble classic terra cotta roof tiles, the tiles being installed are actually a lightweight synthetic made from recycled materials.

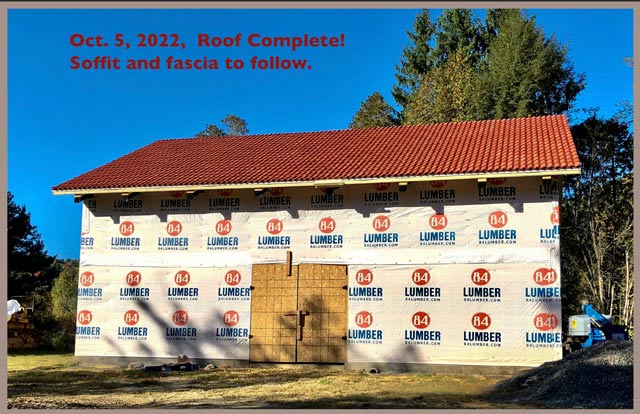

Progress Report - October 2022

The building now has a complete roof and we received a much-anticipated delivery.

The roof tile installation is complete. This building will have a very distinctive appearance at the museum. Trim details are soon to follow.

On October 5 a truck arrived in Coolspring with a very precious cargo aboard. The Graz engine was finally here! It took several years of planning, and a long wait through the COVID-19 pandemic, but the engine completed its 4000+ mile journey from Hof, Germany, to Coolspring.

On a beautiful, sunny morning, the crew stepped into action and began unloading crates of engine parts from the truck.

Once offloaded, the crates were moved into storage for the winter. The forklift definitely got a workout on this delivery.

The Graz engine components were well-packaged before shipment. They will remain in storage until the Diesel Centrale CPM building is ready for them. It's a great relief for all involved to see this shipment at its destination!

Progress Report - April 2023

Construction of the building is resuming after a break for the winter. Windows were recently installed.

Also, the door openings have been framed for the doors that we selected. Doors will soon be installed, followed by insulation and masonry work. Preparations are under way for installation of electrical components.

Progress Report - May 2023

The brick exterior of the building is complete and doors are installed. It's time for a tour!

Adding the brick really enhances the appearance of the building and gives it character. It has warmth even on a cloudy, rainy day.

The doors provide the scale of the interior and the elegant windows are inspired by the arch-top windows of the original Diesel Centrale.

Steel roof trusses give the building an appropriately industrial ambiance. We're looking forward to seeing how they complement the interior finishes and lighting.

The foundation for the Benz engine is the simplest of the three foundations in the building, but is substantial nonetheless.

Massive, deep, and complex, the foundation for the Graz engine is in the center of the building.

The Augsburg engine will be installed on this foundation in the not too distant future.

Progress Report - June 2023

The building really shines on a sunny day! Also note that exterior lighting fixtures are installed.

First engine in the building is the Benz. Compare this photo with the restoration photos from April 2021, above. Placed temporarily for now, it will soon be fastened to its foundation.

Progress Report - October 2023

With the building exterior nearing completion, it's time to concentrate on the interior. Drywall is in place and first paint work is under way. The drywall will provide a "canvas" for any future finishes.

The interior is now much brighter! The Benz engine will have a good home and will be well displayed in this corner of the building.

Progress Report - November 2023

It's been a long journey. Parts of the Graz engine are being unpacked after their trip from Germany. This photo shows the engine's nameplate on the cylinder.

The base, crankshaft, and cylinder are staged in temporary storage and are being readied for installation in the new building. The piston and connecting rod are already secured in the cylinder.

Last seen suspended from a forklift in Germany (July 2022, above), the halves of the Graz flywheel await their turn to be reinstalled on the crankshaft.

Progress Report - December 2023

The lights are on and it's time for some "night shift" work. This night's job was to move parts of the Graz engine from temporary storage into the Diesel Centrale CPM building and stage them there for assembly.

Each half of the Graz flywheel made a short trip from temporary storage via forklift.

This photo shows the Benz engine (left) and some major parts of the Graz, including the flywheel halves, cylinder, and base with the crankshaft.

The heating system in the building is now operating so that engine assembly and installation can proceed through the winter months.

Progress Report - June 2024

The bricks provided by generous donors are now featured in this covered walkway. Recently added to the building, the walkway includes a pair of benches, a comfortable place from which to read the inscriptions on the bricks.

Just above the walkway, a bright, red and white sign now highlights this entrance to the Diesel Centrale exhibit building.

The base for the Graz engine, the engine's air compressor, and air receivers are in preliminary locatons. Soon, we'll be drilling concrete for fasteners to secure the equipment to the foundation.

Progress Report - November 2024

The benches outside Diesel Centrale CPM carry appropriate, and welcoming, inscriptions.

The Benz engine rests on its foundation, waiting to be fastened down and plumbed.

More pieces of the Graz engine are installed. One half of the flywheel is in its pit, and the cylinder is in place on the base. Soon it will be time to fasten the engine and its air compressor to the foundation.

Out of storage, the Augsburg engine is finally off of its timber base and in place on its concrete foundation.

Progress Report - November 2025

The base of the engine is grouted and bolted to the foundation and the flywheel is installed.

With the large pieces in place, work is now focusing on getting the piping, valves, and smaller parts installed.