Spring 2024

The Marinette Story

Part 2: CPM Marinette

By Paul Harvey

The Marinette

Our Marinette engine had a very unique history before

arriving here. But, let’s wind up our time travel by just going back

50+ years. I was just beginning collecting and had visited John Wilcox

at Trail Run. I was so impressed with his 40 hp Bruce McBeth

twin-cylinder vertical as I had never seen anything like it before.

John said he knew where there was a large three-cylinder engine, but it

was in bad shape. He was involved moving another large engine to his

collection, and didn’t want this one. So, I was off to Freeport,

Pennsylvania, as another adventure unfolds. Wow, yep, the engine was a

large three-cylinder Marinette located in a big mill. So, what do we

know about the engine’s history? Although the mill had closed, the

elderly miller lived next door and provided me with some history!

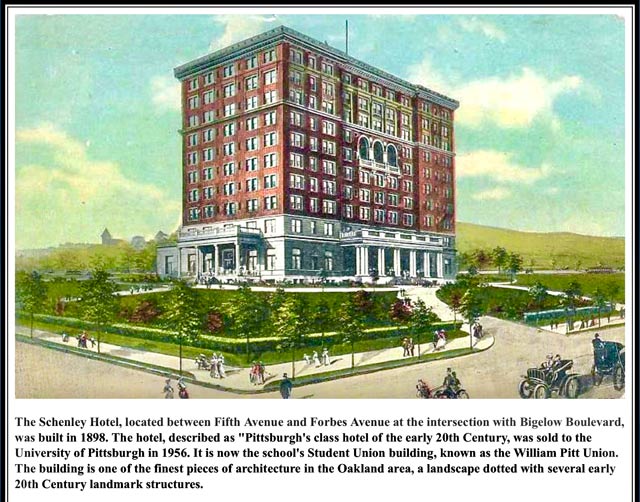

I was told that the engine was originally installed in the Schenley Hotel in the Oakland section of Pittsburgh. It was used to generate electricity. This practice was common in Pittsburgh. With the advent of commercial electricity, the engine was no longer needed. The hotel is still in use today by the University of Pittsburgh for apartments and meeting facilities.

Sometime later, the engine was removed from the hotel,

and relocated to Valley Mills, in Freeport, Pennsylvania. Valley Mills

is located on Buffalo Creek close to where the creek joins the Allegheny

River in Freeport. The mill had a water turbine but the millers wanted

the backup of an engine during times of low water.

The original mill burned during the Civil War. The Mickey family bought the site in 1871 and built the current mill, as shown. It operated until 1965 under three different families.

Most commonly, it is known as Valley Mills or Mickey’s

Mills. It specialized in grinding winter wheat and buckwheat. The

building is still intact and preserved by the Freeport Area Historical

Society. The map shows the location of the mill.

So, I had just found a very large engine; much bigger

than anything I had ever moved. I had just acquired the “tilt bed,” a

tandem 1956 S model International with a big winch. So how to proceed?

The engine had been added on with a crude building. The

Historical Society wanted the mill restored to water power, so that

engine had to go. This situation was very fortunate for me, as they

wanted it removed.

This very poor photo shows the engine moving day in

1971. The engine house had been removed, and its location can be seen

over the tractor. Soon, it was on my truck and on its way to

Coolspring. My Dad, Earle Harvey, and a friend, C.A. (Al) Burcher,

helped on the move. It went very well.

I certainly want to acknowledge Francis H. “Dutch” Laube

(1949-2017) who made having the Marinette at CPM possible. He was CEO

of Freeport Brick, and very community oriented. Leading the effort of

saving of the mill, he graciously made the engine available here. His

dream was to restore the mill to water power.

Tranter Manufacturing Company

It has been a good time travel trip, but let’s just side step a bit to visit a very old company in Pittsburgh. Tranter most likely played an important role in saving our engine. OK. I will explain, as we are looking through some of their nice old shops. We are at 105 Fort Pitt Boulevard at the edge of downtown Pittsburgh. It was called Water Street back then. Tranter was established in 1836 and incorporated in 1891. It survived into the 1970s! Originally it was building all sorts of heavy equipment, catering to the mining industry. But as time passed, Tranter became a reseller more than a maker. They would acquire used equipment, tune it up a bit, and resell it. Probably this is what saved our engine!

Back in Coolspring, we find our engine has a Tranter name plate just below the original Marinette plate. Sooo, although there is no documentation of it, one could easily surmise that Tranter acquired the engine from the hotel, saving it from scrap, and resold it to Valley Mills in Freeport, Pennsylvania. This path seems to be their business practice at that time. Hmmm! What is your guess?

Turner-Fricke Connection

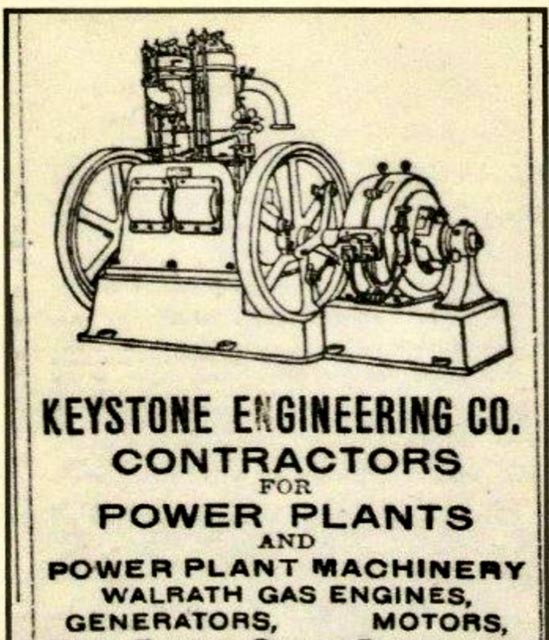

About 1900, we find the ambitious George Turner was

named as the Pittsburgh area sales representative for the Marinette

engine. He did a marvelous job saturating the area with these engines.

He soon partnered with Henry C. Fricke (Pronounced Frick - E) to

form the Keystone Engine Company in 1901 to install the Marinette engine

in various locations. This business was extremely successful.

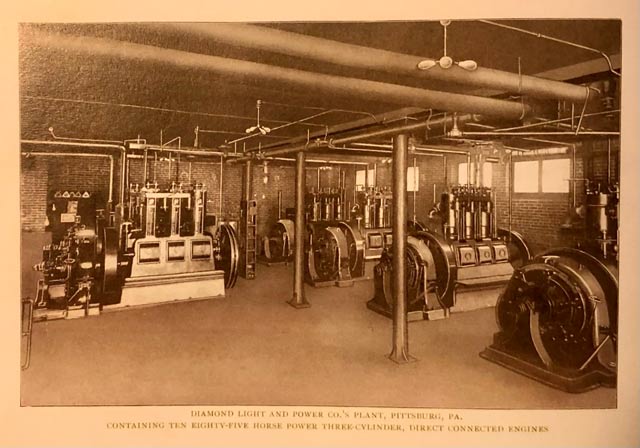

Probably their most ambitious and successful effort was electrifying the Diamond Market Square of downtown Pittsburgh. This enterprise actually became the forerunner of the present Duquesne Light Company.

The Diamond Market Square plant went on line in 1903.

It contained 10 three-cylinder, 85 hp Marinette engines direct

connected to generators.

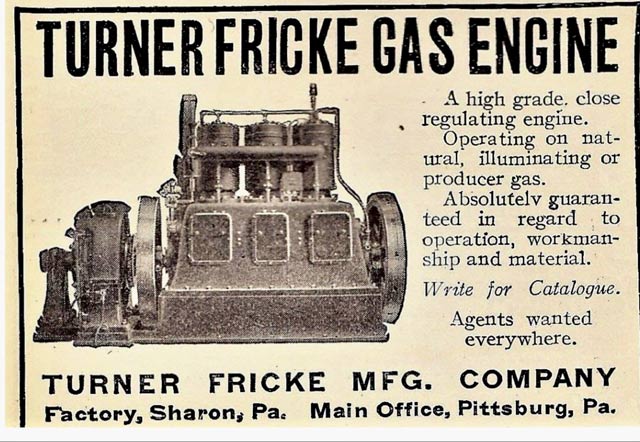

But Turner and Fricke were not satisfied with this

accomplishment and created the Turner-Fricke Manufacturing Company to

produce vertical gas engines. Amazing that they wanted to create their

own engine despite the Marinette success!

Their engine was successful but so different from the

Marinette. Considering the graceful lines of the Marinette, the TF was

much more massive. It was built for hard work also. It was a “T” head

design which had the valves in the block, as opposed to the overhead

valve design of the Marinette. Examples of each are operational at CPM.

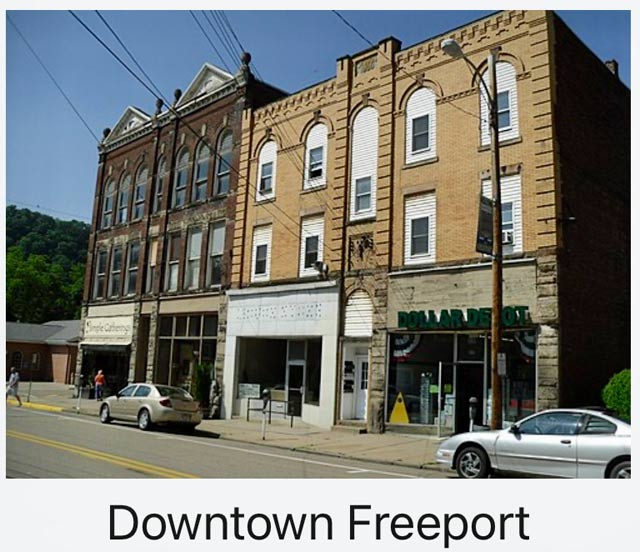

Freeport and the Mill

So where did our Marinette spend its working career? To

answer that question, we have to travel back to the 1790s and see what

was happening along the Allegheny River near the mouth of Buffalo Creek.

Wow! A town was forming! Going way back to the 1760s, we find David

Todd and his brother William acquiring a large portion of riverfront

property here. They sold 27 lots for $24.00 each there. But they had

the stipulation that all the riverfront was free to all sorts of

vessels. No charge could be made for docking, unloading, or loading.

Originally known as Todd’s Town, the name was changed to Freeport in

1833.

Freeport was an ideal place for a mill, with Buffalo Creek joining the Allegheny River and Pittsburgh close by. Excellent access to good markets!

The first mill built on the site was in 1816, and a mill has been there ever since. The present mill dated to 1871, and was named the “Freeport Flouring Mill.” In 1881, the “Freeport Journal” notes that the mill was renovated with a new boiler and steam engine. The dam on Buffalo Creek was updated and the water wheel was replaced with two turbines. In 1883, the name was officially Valley Mills.

In 1898, Elmer Mickey and his family moved to Freeport

and purchased the mill. From that day on, most people called it

Mickey’s Mill. Although maintaining the water turbines, Elmer purchased

a large gas engine. He also installed a small engine and mill for

little jobs. In 1942, Mirl Mickey took over and they were producing 500

barrels a day of the best four in the valley. Mirl finally closed the

mill in 1965 due to failing health. Obviously, our Marinette engine had

a busy life!

The later one-story addition that housed the large gas

engine, the Marinette, was attached to the mill where the window is

absent. It was torn away by 1971 when I removed the engine. The engine

has a large, direct connected clutch pulley that extended into the main

part of the mill to operate the extensive maze of shafts, pulleys, and

belts. Impressive! The small engine and its mill were located on the

main floor of the building, handy to grind a couple bags of grain. It

was an International Harvester 4 hp hopper-cooled Mogul engine. The old

miller really loved that engine and it probably kept the mill open a few

more years.

Our Engine

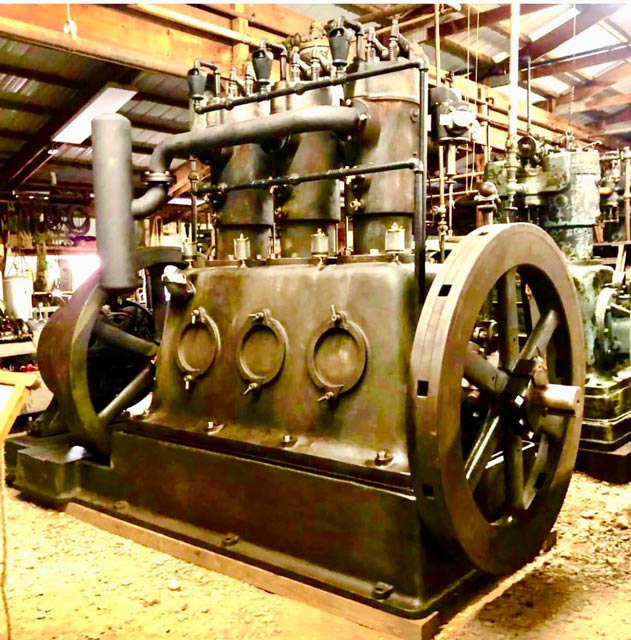

We have just returned from a marvelous time travel trip

and have learned so much about the Marinette engine. Enjoyable journey,

but let’s return to Coolspring to look at our engine! A story that

spans 50 years.

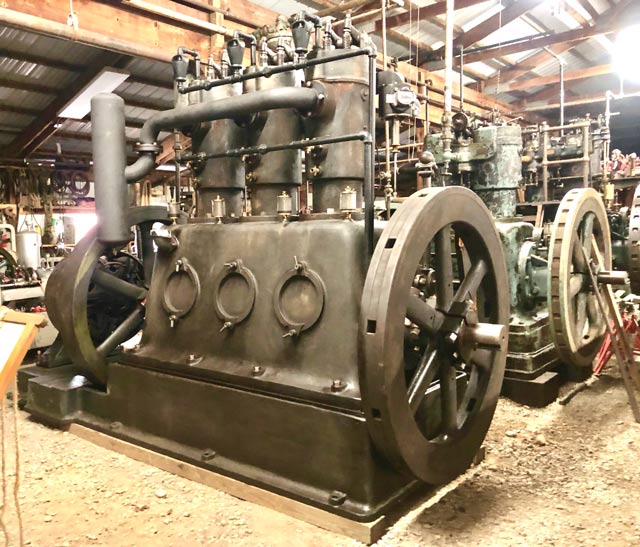

The engine is a three-cylinder vertical of 10¼-inch bore and 14-inch stroke. Its serial number is 386 and it is rated 75 hp. This view shows the vertical push rods that operate the overhead valves, and the igniter. The vertical governor controlled the main mixer, adjusting the amount of gas and air each cylinder got. The secondary mixing chambers allowed each cylinder to be fine-tuned. The wooden platform and stairs were original to the engine. Note the holes in the flywheel used to insert a bar to position the engine for starting. The actual starting was then done by compressed air.

This is a view from the other side of the engine.

Evident is the exhaust system and massive sub base.

These two photos were taken through the middle

inspection cover. Amazing, the connecting rods have strap end bearings.

Note the cam shaft and tappets.

When acquired, the engine was really worn out. It had a

hard life.

The heads were beyond repair but there were new patterns

stored in the mill. I brought them home back in 1971 as a

curiosity. Reflecting, they might have been made by Tranter, knowing

how bad the heads were. However, when Justin restored the engine, he

used the patterns. He felt they were the best he ever used.

Epilogue

Let’s let our time travel take us back to the present.

It has been a great voyage. The Marinette is back to where I unloaded

it in 1971. But, look! It’s different and runs so well. Why? Justin

Jenkins took it back to his shop and did a total rebuild. So many

parts, including the heads, had to be remade. With his magic, it lives

so well again. A long and successful story.