February 2022 - Extra

Why Diesel?

By Paul Harvey

Coolspring Power Museum worked diligently all last year

upon Diesel Centrale CPM, an installation to display three vintage

Diesel engines. We certainly believe that these engines are very

significant for the enthusiast and visitor alike. But, why Diesel

engines? One might ask how they are significant compared to all

the fine gas engines that the museum displays? Good question, so

letís go on a bit.

What is a Diesel engine, and how does it differ from a

gas engine? Simple! The Diesel employs a much higher

compression pressure, heating the air in the cylinder hot enough to

ignite the fuel when injected. The gas engine uses lower

compression pressure and employs a spark plug to ignite the fuel.

OK. Both engines burn fuel and produce power. But why is one

better than the other? The Diesel is more efficient due to its

higher compression and heavier fuel. Whoops! Iím getting

ahead of the story.

So now, let us time travel back to the 1800s and look at

two great German engineers who were pioneers in early engine

development. They lived a generation apart from each other, and

each made a contribution that is making our lives more pleasant today.

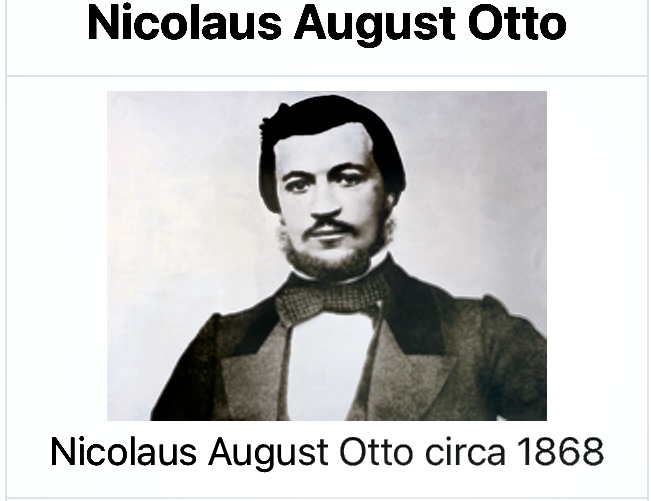

First, we will meet Nicolaus Otto, born 1832 and died

1891. In 1876, he developed the four-stroke cycle gas engine which

is still the mainstay of our lives today. Yep! One is in your

car! What an invention for all of us!

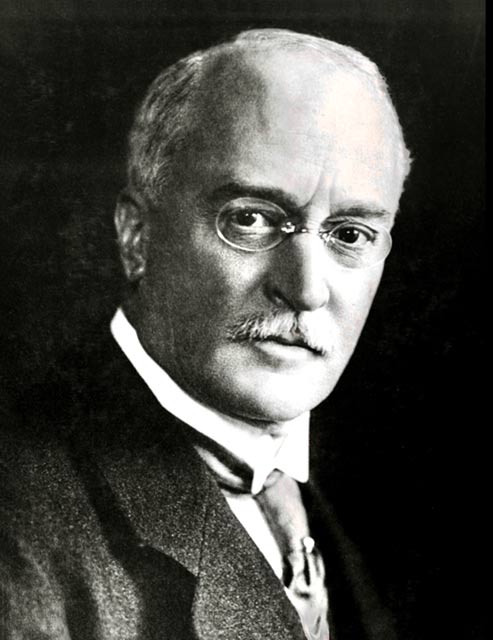

Now we meet Dr. Rudolph Diesel, born 1858 and died 1913.

Working with Maschinenfabrik Augsburg, he produced the first compression

ignition engine in 1897. A new era of engines began! His

engines are used today worldwide, from cars to trucks, to heavy

equipment, and to the largest ships.

CPMís Augsburg engine, serial number 185, was

built in 1903 when he was at the factory. Wow! Thatís

significant. Perhaps he looked at it and approved. It is

still here today.

Now, letís just get a bit technical and explore the

differences of the machines created by the two great engineers. I

think it can be simple and amazing. Weíll give it a try!

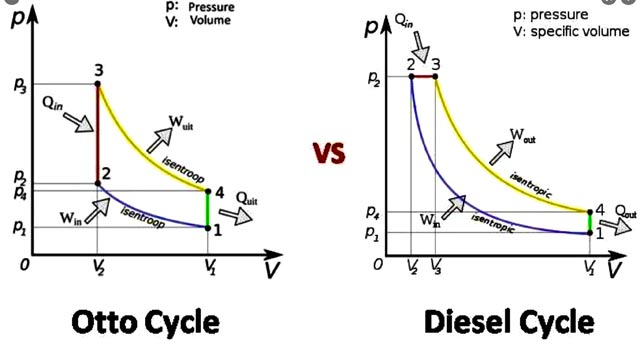

These images are indicator card diagrams of what happens

in the cylinders of both the Otto engine and the Diesel engine during

operation. Donít look much alike, do they? Well, there is a

simple explanation and letís take a look. First, note that the

cylinder pressure is shown on the vertical line, and the cylinder volume

is on the horizontal. Any ideas yet?

OK. I will explain. But first, I will

confuse you more to say that the Otto cycle shows constant volume

expansion and the Diesel cycle shows constant pressure expansion.

So here is the little secret!

Letís start with the Otto cycle. First look at the

blue line from 1 to 2. Got it? That represents the engineís

compression stroke. At 2, the engineís fuel is ignited by the

spark plug and the pressure goes up to 3, as shown by the red line.

Increase in pressure but not in volume, so constant volume expansion.

This is the engineís power. Now go from 3 to 4, the yellow line.

Higher pressure as the engine produces its power. The green line

from 4 to 1 represents the exhaust, and we are back to the beginning!

Hmm! Simple!

Now, letís look at the Diesel cycle. Somewhat

similar, but a very big difference. Again, the blue line from 1 to

2 shows the engineís compression. Then, at 2, the fuel begins to

be injected. Yes, it is injected slowly as opposed to the big bang

of the Otto cycle. The red line from 2 to 3 shows the combustion of the

fuel, increasing the volume inside the cylinder, but not the pressure.

Just inject more fuel during combustion and get more volume, pushing the

piston down for more power. Smooth and efficient! Hence, we have

constant pressure expansion. The yellow line from 3 to 4 is the

power of the engine. The green line from 4 to 1 is the exhaust

stroke, taking us back to the beginning again. Think about it a

bit, and it becomes simple! Now you know the difference.

Great.

Note that the area inside the four colored lines

describes the amount of useful power that the engine produces. Simple,

huh?

Both these cycles are still very practical for us today.

The Otto cycle can use lighter engines very practical in automobiles,

lawn mowers, garden tractors, and the like. Then the Diesel cycle

is used in trucks, heavy equipment, ocean going ships and all similar

uses. We owe the two men a lot to make our lives easier and more

pleasant today.

INJECTION TYPES FOR DIESELS

Now, I would like to take a brief look at the types of

fuel injection for the Diesel engines. We will chat a bit about the

three main categories: air-blast injection, solid injection, and common

rail injection. Donít worry, these concepts can also be simple!

AIR-BLAST INJECTION

Air-Blast Injection is Dr. Dieselís original design and

is used on the engines that will be displayed in CPMís new building,

Diesel Centrale CPM. The museumís Augsburg engine uses this

principle.

So how does it work? The Diesel engine has a

compression pressure of about 500 psi, so compressed air at 800 psi is

needed to ďblastĒ the fuel into the cylinder for combustion. This

method provides for fine atomization of the liquid fuel. Fine

atomization provides for more oxygen exposure, which yields better and

more complete combustion. Letís take a peek!

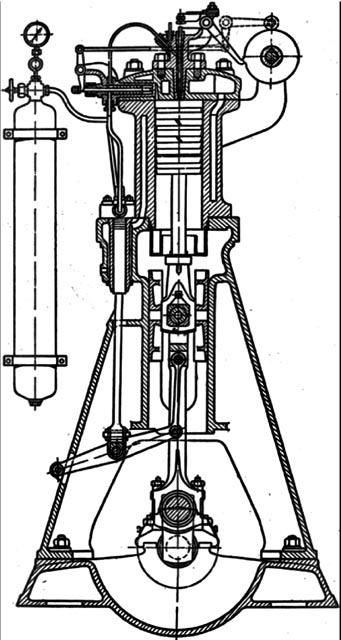

This illustration shows a basic early air-bast injection

engine. Note the air compressor attached to the left side of the

engine. Itís supplying air to the storage bottle as well as to the

injector on the top center of the engine. At the precise moment,

the cam shaft, top right, by a rocker arm, opens the injector and

combustion begins. Yep, the engine produces power. Got it?

The system worked well, but was cumbersome and fraught

with all sorts of problems. But it was the start! It

will soon get better.

This is Dr. Friedrich Buschís 12 hp Augsburg-Nurnberg

type DM air-blast engine. It is a few years later than our

Augsburg engine. Note the two-stage air compressor at the right

base of the engine, and the pressure gauges and air tanks.

I am honored to have been allowed to start it with his

supervision.

SOLID INJECTON

As the years passed, metallurgy and machining progressed

to the point that an injection pump could be made to directly deliver

high pressure fuel to the injectors. Pressures exceeding 20,000

psi were needed. This development did not happen until the late

1920s, but it eliminated the air tanks and air compressor. Wow.

One small pump with lines to the injectors. Simple! Since the

fuel is a non-compressible liquid, the process was termed ďsolid

injection.Ē

We will take a peek at the two basic types.

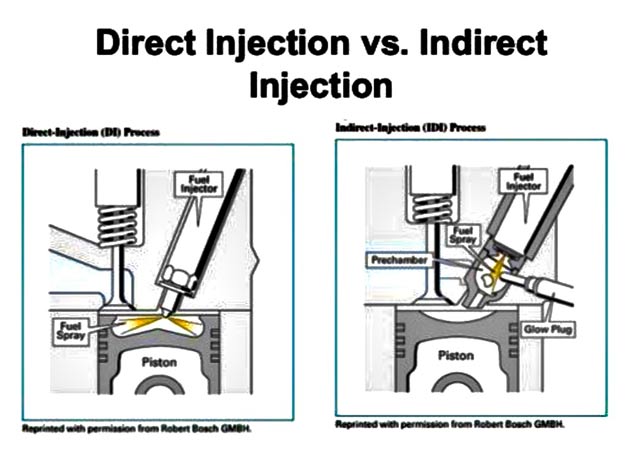

Direct injection, shown on the left, placed the injector

in the cylinder, direct from the fuel injection pump. Combustion

occurred in a well in the piston. This system was used in the

earlier Dodge pickups with Cummins diesels, and employed a mechanical

Bosch injection pump. It was simple and very effective.

Indirect injection used a pre-combustion chamber, often

warmed by a glow plug for starting. The pre-ignited fuel was then

discharged into the combustion chamber, where the ensuing combustion

took place. Some of the other truck engines used this principle.

Both systems are in common use today and are very

successful. Still with me? Itís simple!

COMMON RAIL INJECTION

This is the third and last category that I will discuss.

Itís been around a long time and now popular again. So, letís take

a peek and make it easy.

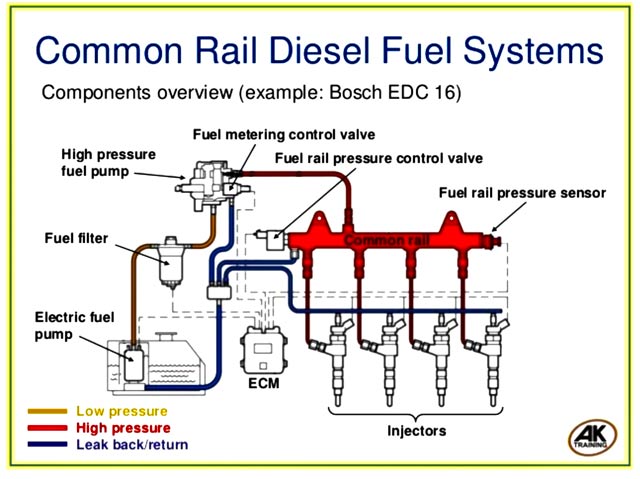

Just as the name implies, there is a ďcommon railĒ or

fuel manifold that is pressurized to 30,000 psi or above, that supplies

the fuel to the individual injectors. This arrangement is shown in

the red portions above. The fuel tank is seen at the lower left in

the illustration above. A fuel pump delivers the fuel through a

filter to the high-pressure pump. This flow path is shown in

yellow. Still with me? Trying to keep it simple!

The high-pressure pump, remember- over 30,000 psi now,

delivers the fuel to the fuel manifold or ďcommon rail.Ē The

injectors act at the precise time, either by mechanical or electronic

means, to put the fuel into the cylinder to be burned. Wow.

The engine is now getting power. Any overflow or leakage is

delivered back to the fuel tank by the blue lines. Simple, but

very effective! Got it?

This common rail injection system atomizes the fuel into

very fine droplets which have more oxygen exposure, giving better

economy. Interesting that this result was what Dr. Diesel was doing in

1897 with his air-blast injection! Technology advances, but the desired

end is the same!

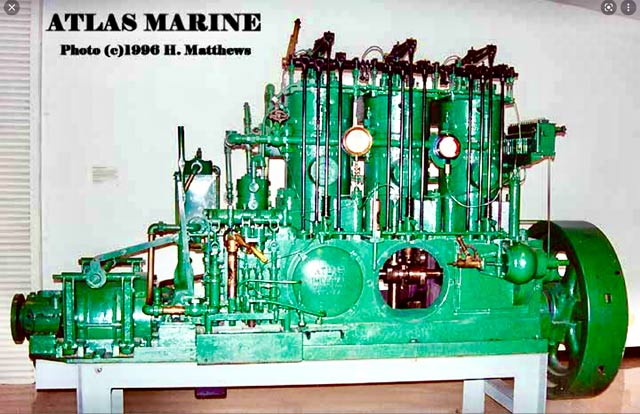

It is interesting to note that Atlas Imperial Diesel of

Oakland, California, developed a common rail engine in the 1930s.

These engines were both successful and beautiful.

There are many other variations of injection for Diesel

engines, but air-blast, solid, and common rail are the basic types.

The others are beyond the scope of this article.

It is my hope that the reader has found this article

about the operation of the Diesel engine both informative and easy to

understand. I have enjoyed writing it and I hope you have enjoyed

reading it.