December 2021 - Extra

The Air-Blast Engine Project Trilogy

Part 3: Fall Finale

By Paul Harvey

Finally, after so many different names for our project,

we chose Diesel Centrale CPM. Now, we have a catchy and unique name

and logo. So why this name? It is in honor of the great

plant of air-blast engines still existing in Austria.

Diesel Centrale - Austria houses an array of Graz

engines that provided electricity for the surrounding industry. It

operated from the early 1900s until the 1950s. It remains intact.

Note the peaceful setting and the magnificent

architecture. It is our intention to capture those qualities here

in Coolspring.

Wow! What a beautiful Autumn. And so warm

and sunny. I was greeted by these glorious leaves each morning.

Great day for writing.

So, let’s take a peek at what is being done. Great weather means great progress! The building site was safely fenced for our Fall Show, and many visitors viewed and enjoyed it.

Tom, a master plumber, began the extensive array of

piping needed to supply each engine. Water lines, air lines,

electrical conduit, and the list goes on.

Another view of the pipe work. Since the water

discharged from the engines needed gravity return, a gravel bed had to

be carefully placed with a drop of

¼ inch per foot. Note the conduits

through the foundation for the pipes. It was all done well.

We have confirmed the roof tile and wall brick designs

and placed deposits to lock in the prices and ensure delivery in March

2022. Exciting! The tile is a composite material that is

surprisingly lightweight yet very durable. It is made by Brava

Tile. Our choice is called Terra Cotta and closely resembles that

used in Germany. The bricks are Canton design made by Glen-Gery.

Many styles were examined, and these are a nearly perfect match to

photos kindly supplied by Dr. Friedrich Busch.

A 1,000-gallon elevated tank, restored by Stanton

Dynamics, will provide cooling water for the engines. The water

will then drain into the 1,250-gallon sump tank, made by Punxsy Burial

Service, to be pumped into the elevated tank to repeat the cycle.

All pipes to the sump will be through the green riser.

Great, but where does the water come from? So…

We need a water well! I contacted Forsyth Drilling

in DuBois and a suitable day was chosen. Wow! What a rig.

He had to pound in 42 feet of steel casing to get through the gravel and

into the water-bearing sandstone. Finishing at 100 feet, he found

an almost unlimited supply of good water. The submersible pump has

now been installed and all is “well!” Besides filling the tanks, it is

imperative that cold water be supplied to the engine intercoolers for

proper operation. As time goes on, there will be many other uses

for this great water on “The Hill.”

So, what’s happening with the engines? Some

progress and some delays. Let’s take a look. Friedrich sent me

this photo of the Graz happily running in his shop in Hof, Germany.

The COVID-19 problem postponed our making a trip to learn its operation,

dismantle it, and to move it to CPM. We hope 2022 will be better.

The Benz has been extensively restored by Gordon Jones

and will have a test run soon. It will winter in his shop.

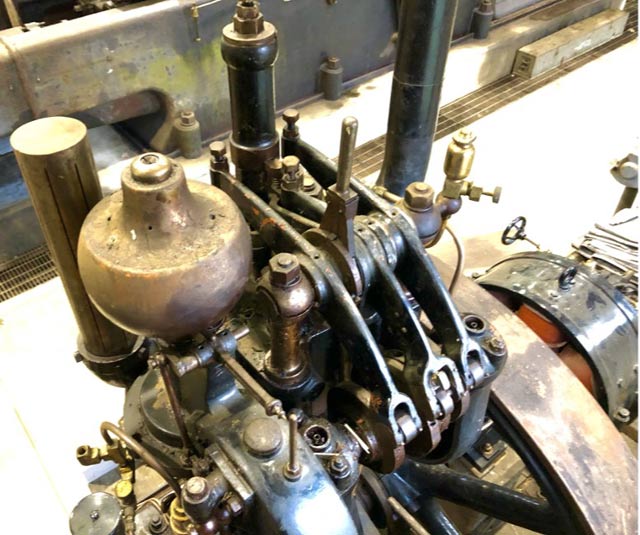

Chris Austin and I have studied the complicated piping

on our Augsburg. It is of the early design where the first stage

of the injection air is bled from the power cylinder. The middle

rocker arm has a shiftable roller that can operate the starting air,

then bleed off injection air. This design was soon replaced, so

this will be the only operating engine in the world using it.

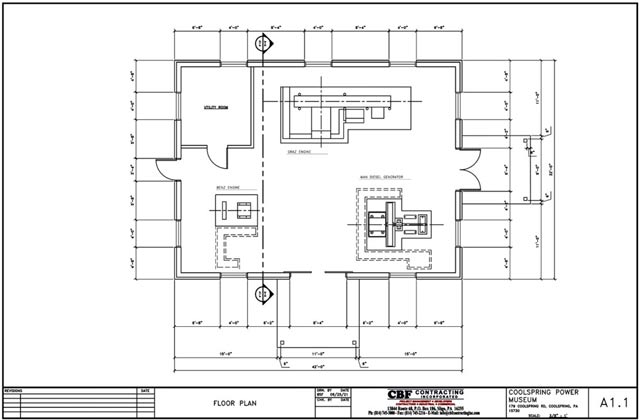

This drawing is the final floor plan of Diesel Centrale

CPM and represents a lot of thought, measuring, and rearranging. Whew,

glad that’s done! One can see the locations of the three engines,

as well as the utility room. Doors are designed for handicap access as

is the central floor. The windows are ample and well placed.

It will be a beautiful structure.

The piping for the floor heat has been placed and

tested. The heater will be installed in the utility room and will keep

the building cozy all year round.

The floor was poured, and the block walls were filled with concrete. Total of 19 yards! Great job!

Finally, all the back filling was done, and heavy rubber covers were placed. Ahh! It’s now ready for a long winter’s nap. 2021 has seen so much progress and we are ready to have a building in 2022!

Diesel Centrale CPM has been an exciting, although

challenging, project. We have graciously appreciated all your

donations and support. Gordon Jones and I have spent many long

hours on it but enjoyed it all. A classic power house with three

Diesels is a dream coming true. It will truly be a World Class

exhibit. We will dream on! As Winter is happening, I reflect back

to the sunny days of Summer. They will come again. But for

now, we all wish you and yours a very Merry Christmas and prosperous New

Year.