December 2021

Roaring Run Station

By Paul Harvey

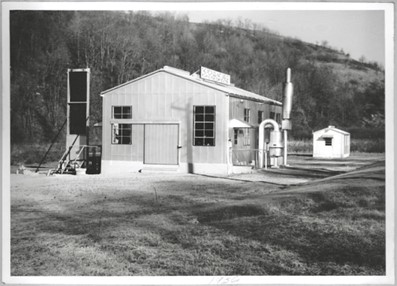

In 1956, the Peoples Natural Gas Company opened their

new Roaring Run Station to compress and transport natural gas.

Named for the bounding creek behind, it was considered “state of the

art” for its day. Note the small building behind, also built at

that time, that was used as the office. This is the story of how

Roaring Run came to Coolspring Power Museum.

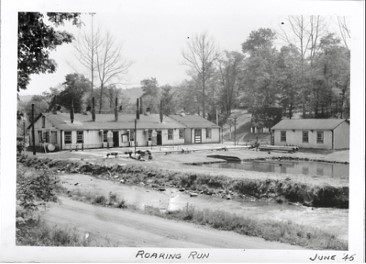

But first, let’s take a step back in history to see the

earlier station. Yep, there’s the creek roaring along. Look all

those stacks! Wonder what was inside? Perhaps someday we

will discover the answer.

Now we will time travel to November of 2020. Ben

Steffy, our board member as well as a Peoples Gas employee, emailed me

that their Roaring Run station was going to be replaced with an

automated unit. They would be happy to donate the old structure to

CPM. Wow! Wonderful, but so many questions to be

answered and so much to consider. So, let’s first take a look.

I met Ben one mild November day at his home in

Smicksburg, Pennsylvania, and he took me for a tour. This road

went one way then the other and we were getting out in the middle of

nowhere! He assured me we were near Apollo, Pennsylvania.

Finally arriving and seeing, what a delightful surprise I found!

The structure was magnificent and looked like it was

just built. The engine was working well and the interior had all

the great aromas of a working station. An experience to be

remembered!

The nameplate for the building was still proudly

displayed on the side near the door. That meant the building was

all bolted together with no welding. In those days, buildings were

designed to be moved as the need arose. Hmm. So, it

could come to CPM and be re-erected. Our interest increases, as

does our dreams for future use.

The other side of the main station. A rolling

overhead door has been added as well as a partition to make the back

side a work area. Parts bins, workbench, air compressor, pipe

threader, and drill were located here. Good idea!

The office is a 12 by 14-foot structure in excellent

condition. The possibilities for future use are endless. Ben

and I sat down a bit to enjoy the cozy warmth and reflect on the

possibilities. Of course, the restroom was welcome. It’s

looking good!

The engine, that day happily working, is a massive

Cooper Bessemer model GMX, built in 1955 or 1956. It makes 400 HP

at 400 RPM. With 8 cylinders of 9¾-inch bore and 10½-inch

stroke, it is a monster! The power cylinders are in a “V”

configuration with 4 large compressor cylinders out of one side.

Although offered to us free of charge, we had to decline the donation of

the engine. It just was beyond our capabilities and did not fit

our goals.

CPM was impressed with the structure and donation offer,

and approved its acquisition formally at a Board of Directors meeting.

Now the long process of getting it here began!

I wrote a letter to Peoples Gas, gratefully accepting

both buildings and understanding that they would prepare them for

removal and transport them to the museum. They happily agreed.

First, they had to transfer operation to their new

station and disable the old faithful engine. Simple and done.

Their pumping never ceased. Next, they had to have an asbestos

abatement program done, and inspections completed to certify that it was

safe to donate to us. Sure glad we were not involved in that!

Then time dragged on well into 2021 and winter was

approaching. So, it would probably happen in 2022. OK,

that’s good. But in the first week of this November, Phil

Dobson, of Dobson Contracting, called to say two tractor trailer loads

would be arriving in two weeks. Excited, we chose an appropriate

storage area for the buildings to be unloaded. Progress! We

all knew Dobson Contracting as they have done many projects here.

An amazing feat, the Dobson crew unbolted the structures

by hand, causing no damage. They did not use any torch work. All

building sections were carefully numbered with the sequence for

reassembly, and pictures were taken. Wow, that’s excellent!

It was exciting as the first trailer load arrived that

sunny but cold day. All sections were stacked in order, and no

damage done to them. I was impressed!

Phil and crew did a fantastic job of unloading and

placing for us. I just sat on my Gator and watched.

Finally, all sections and parts were placed, and well

suited for the winter. Now, thoughts turn to its use. Hmmm.

A waterworks building? A machine shop? And where

will it be placed? Lotsa decisions and a long winter to

decide. The possibilities are endless, and it is awaiting our

decisions.

Part of the sections in winter storage. A big

project that turned out so well!

CPM would like to extend heartfelt thanks to all who

helped with this huge project. First to Peoples Gas Company for

believing in the museum enough to make it happen. Their efforts

were tremendous. Special thanks to Ben Steffy for coordinating so

much for us. And all our gratitude to Dobson Contracting for the

care that they gave to make re-erection easy and possible. Working

together, the impossible came true. My apologies to all who I have

missed.