November-December 2018

Finally Open

By Paul Harvey

Yes, the Machine Works Building is finally open to all of our visitors! It made its grand debut at our recent fall show, after waiting forty-four years. I was exuberant! Chatting with visitors and running engines was delightful, and all went so well. Six engines were operational at the fall show, and more will be running next June. It was about time!

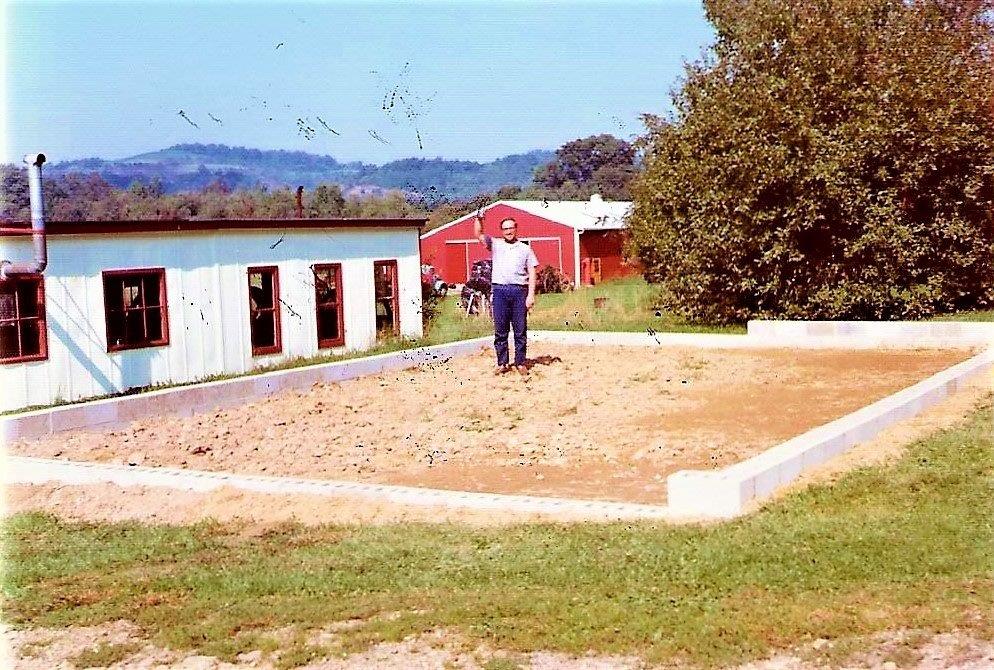

I started constructing the building in 1974, as seen in Photo 1. As the collection expanded and John Wilcox and I began working together, it became the third building on the grounds. Preceding it was the Founder's Engine House, then called the Engine House, and the Power Technology Building then known as the Big Barn. From its inception the Machine Works was to be a machine shop, hence its name.

But progress was fraught with problems. We did get a few machine tools assembled inside, and got one operational. However, during those early years, the engine collection was rapidly growing. I was spending almost every weekend hauling another "goody" home; some were quite large and required several trips. So, it became easy to let the progress of the Machine Works lag, even to the point of using the building for storage. We all know how that goes! Soon the building was filled with "junk" beyond hope.

During the ensuing years several attempts were made to resurrect it, but all seemed to fail. A little progress would be made then soon lost again. During those years, we continued hoping for a machine shop. A turning point for that endeavor was discovering that my Dad and I designed the building’s roof trusses such that they were too light to support line shafts. So back to the storage use again.

Fortunately, the delays all ended four years ago with a complete restoration of the building exterior that had it sporting bright new paint. A sincere attempt was started to clean the inside, and this effort gradually and successfully happened. The building was insulated and new rough-cut lumber was installed on the inside giving a very pleasant ambience. With the approval of our Board of Directors, I decided to make it a display place for special engines. And so, it happened! Photo 2 shows its doors open, waiting for admiring visitors on October 18, 2018. It was a special day!

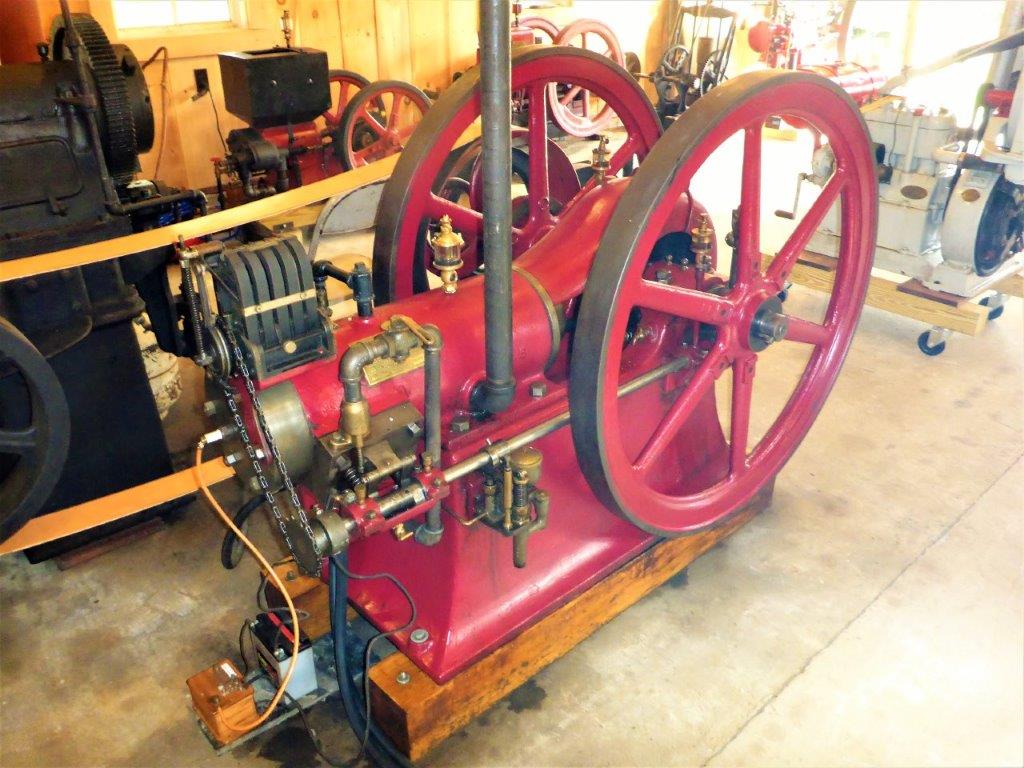

Upon entering we are attracted to a central display, one that has endured since the early 1980s. Here we see a 6 hp Callahan engine, see Photo 3, belted to a Jarecki Steam Pipe Threader noted by Photo 4. I acquired the Callahan from the late Nate Lillibridge many years ago. It was my first really "high-class" engine and I surely enjoyed watching it run. I guess that I was too naive to document its history.

The Jarecki threader came from the old brewery in DuBois, Pennsylvania. The brewery was razed in the early 1980s but I was able to save this machine. Since the brewery was entirely a steam-powered plant, the threader was also steam-powered. Indeed, it is shown in the Jarecki catalog. Note the small steam engine built into its side. The drive belt from the Callahan goes over the steam engine's flywheel. It can thread pipe from one inch through four inches, and John and I used it frequently. I actually threaded a piece of 1¼ inch pipe in October for demonstration. It was satisfying to operate it again.

My very first engine, a 1½ hp Hercules, is proudly displayed on a shelf inside the front window. It is exhausted outside just under the window. Visitors strolling down the entrance road and not entering the building can still see and hear it run. And it did run well all day! I acquired it in 1958 for $5! Beside it is a small Fairbanks Morse Eclipse engine that was found locally many years ago. My wife Marilyn surprised me at Christmas with it back in the early 1970s. It will be running in the spring. Both of these engines can be enjoyed in Photo 5.

Also making its running debut is my 16 hp Jacobson, number 1011. This number makes it the eleventh Jacobson built and one of the oldest in existence. Finishing touches were put on it, as well as on the interior of the building, the week before the show. It is a magnificent machine with its pictorial history shown on the adjacent wall. It is seen in Photo 6.

A relatively new addition to the engine corral is this nice Domestic pump rig. See Photo 7. The engine powers a Domestic duplex pump and is on the original factory cart. It is exhausted through the wall, which makes its operation pleasant. Near to it is a 4 hp Jacobson belted to a Flint and Walling pump jack. These units were suitable for pumping shallow wells and it can be "de-clutched" by means of tight and loose pulleys. Note Photo 8.

Photo 9 is a Stover engine belted to an air compressor. Interestingly, it is a factory rig that includes the cart. The engine pulley is inboard of the engine flywheel assuring better alignment and giving a nice appearance. It is relatively low capacity and pressure, so I am not sure of its intended use.

Awaiting some final touches is this neat little Utility light plant. Photo 10. It produces 100 volts of direct current so it will light some incandescent bulbs as well as operate a DC motor. The diminutive four-cylinder engine is Utility's own product, as is the generator

The next picture, Photo 11, illustrates some of the shelves and various items placed on them. I will easily be able to fill them with small engines, pumps, electric apparatus, dental air compressors, toys, and the like. Many operate and are fun to watch.

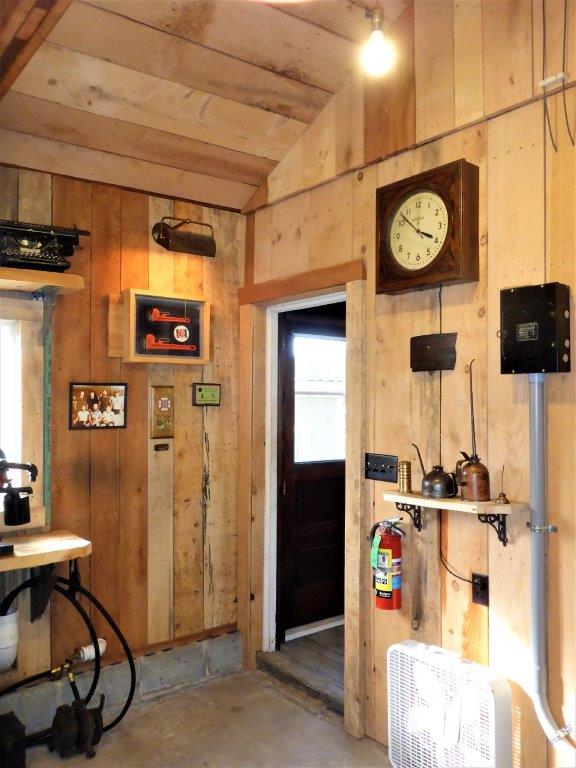

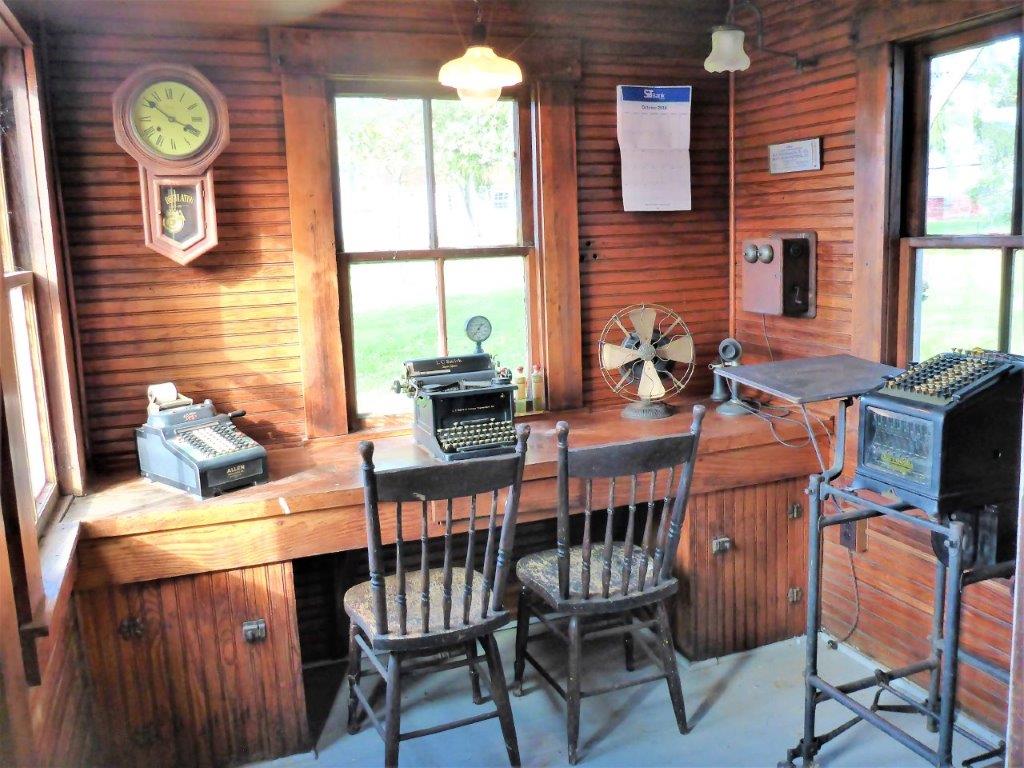

Walking toward the rear of the building, one finds the doorway into the office. This corner is shown in Photo 12. Note the wall decorations and the period light bulb. The electric clock came from a United Natural Gas compressor station. So, let's proceed through the doorway into the office. This portion is actually the office from Starr Station, a crude oil pumping station in Ohio. It was moved to the museum and carefully restored. The furnishings represent how a typical pipeline station could have appeared. Note Photo 13.

Stepping out of the office and looking back, we see the appearance of the structure, illustrated in Photo 14. This is the typical appearance of a pipeline station with its office attached. The large white tank provides cooling water for the building, as well for as the Founders Engine House and McKee Station.

Finally, Photo 15 shows the project for the summer of 2019. This is the 25 hp Nash engine, built by the National Meter Company of New York City. It originally powered an air compressor in the National Fuel Gas Halsey Station. It has waited a long time on its concrete foundation. It will run again!

If you have enjoyed this virtual tour of the Machine Works, why not visit it in person next summer. I'm sure you will enjoy!

Photo 1: The beginning of the Machine Works in 1974

Photo 2: The Machine Works Building in October 2018

Photo 3: Callahan engine

Photo 4: Jarecki Steam Pipe Threader

Photo 5: The original Hercules engine (left) and a Fairbanks Morse Eclipse engine

Photo 6: Jacobson 16 hp engine

Photo 7: Domestic engine and pump

Photo 8: Jabcobson engine and pump jack

Photo 9: Stover engine and air compressor

Photo 10: Utility light plant

Photo 11: A few of the small items on display

Photo 12: Doorway to Starr Station

Photo 13: The Starr Station office interior

Photo 14: The Starr Station office from the outside

Photo 15: Nash 25 hp engine