May 2017

Hot Air Engines

A Beginner's Guide

Part 1: History and Principle

By Paul Harvey

A year or so ago, the museum decided to feature "Hot Air Engines" for its big June 2017 Exposition. I was quite excited as I realized that I knew very little about these unique engines. Two are displayed at the museum and they are fun to watch run, but I had given their operation little thought. Being curious, I set out to understand them, and now I wish to share that fascinating information with you, our readers.

While the museum focuses on internal combustion engines, those that burn the fuel inside the cylinder, hot air engines are external combustion. Similar to fuel for steam engines, the fuel for a hot air engine can be wood, coal or any other heat source which is burned in a firebox outside the cylinder to produce the power, hence external combustion.

One major drawback of the steam engine was the dangerous boiler which contained hot, high-pressure water and steam. It had to be diligently maintained to remain safe. In contrast, the hot air engine used an enclosed volume of air to bounce back and forth from a hot side to a cold side. The pressure was low, and there was no boiler! It was completely safe. A small firebox could be fueled with wood and the engine would operate unattended until the fire went out. There was neither loud noise nor noxious exhaust, and the attendant need not be skilled to keep one running. All it took was building a fire, oiling the machine, and giving the flywheel a little spin.

To better understand this small niche of engines, let's look at our Expo's featured hot air engine, shown in Photo 1. This engine is a very early Rider, built by the Rider Engine Company of Walden, New York. Note that it has two cylinders whose cranks are 90 degrees apart. The hot side is to the right and is warmed with a gas burner. The cold side is to the left and is cooled by the water pumped by the small plunger pump attached. The trapped volume of air bounces back and forth through the upper middle connection. This device amazingly produced power successfully and pumped water easily.

Adapted best for small power applications, the hot air engine was built prolifically in both the United States and the United Kingdom. A frequent use was pumping water from a buried cistern to a roof tank in large country estates or remote hotels. Running water in a remote site! Hot air engines found many uses extended from pumping water for railroad tanks that fed the hungry steam locomotives, to lonely ranches that needed water for the livestock. They continued to live into the twentieth century when electricity finally replaced them.

For a better understanding, we will now time travel back two hundred years to early nineteenth century Scotland to meet the Rev. Dr. Robert Stirling. His portrait is seen in Photo 2. Robert was born in 1790 at Cloag Farm near Methven, Perthshire, Scotland. He was the third of eight children to Patrick and Agnes Stirling. Photo 3 depicts Methven in the 1920s, about a century before Stirling's work there.

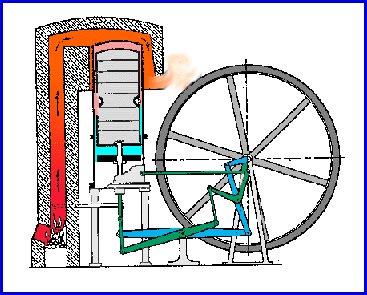

Robert Stirling studied divinity at the Universities of Edinburgh and Glasgow, and was licensed to preach at the Church of Scotland, (Presbyterian) in 1816. In 1824, he was appointed to be the minister of the nearby Galston Parish Church where he continued until his death in 1878. He was 87 years old. However, Stirling inherited his father's interest in engineering and eventually developed a successful hot air engine. History reflects that other attempts had been tried, but none were successful. His 1816 patent shows the engine that we still know today as the "Stirling Cycle" engine. Note Photo 4.

His patent engine featured an "inverted" walking beam principle with the beam below the cylinders and wheel. Another important part of this patent was the "Heat Economiser," now known as the regenerator. Simply, the regenerator was a gob of iron mesh placed between the hot side and cold side. As the hot air was transferred to the cold side, it gave up heat to the mesh. When air bounced back to the hot side, it regained this heat. The regenerator provided a great saving of fuel. In 1818, he built the first practical version of his engine which pumped water from a quarry. To develop this principle, Stirling had to have a firm understanding of thermodynamics, still an infant science. His engine actually utilized principles not known to the scientific world at that time. He must have developed his "cycle" through diligent experimentation. The brilliant young French physicist Sadi Carnot, known as the father of thermodynamics, did not develop the second law of thermodynamics until 1824. His portrait is shown as Photo 5.

Why did Stirling develop the hot air engine? Probably the most reasonable answer is that he had an idea and wanted to see it to completion. Another possibility that many advocate is that he wanted to help his parishioners avoid the terrible accidents that occurred with the steam engine. He witnessed boiler explosions which killed, burned, and maimed his people, and wanted to create a safe power source for them. And so, he did create a safe source of power.

Robert was assisted by his younger brother, James, who was an engineer. They formed a factory to manufacture the engines and found an excellent market. Patents for improvements were granted in 1827 and 1840. A huge engine was built in the 1840s to drive all the machinery at James' Dundee Foundry Company.

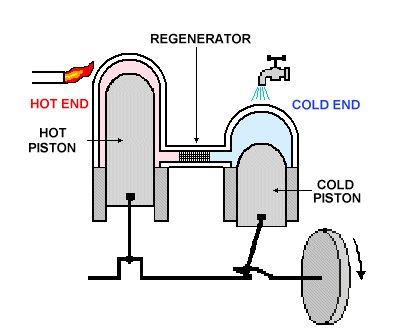

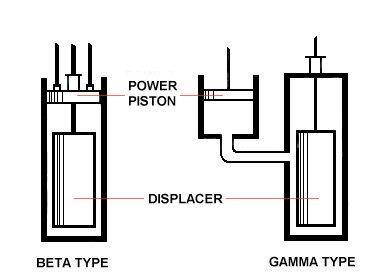

There are several types of Stirling Cycle engines, and I will choose the "alpha" type to explain the cycle. Note Photo 6. For comparison, the "beta" and "gamma" types are shown in Photo 7. The DeLamater Iron Works engine, seen in Photo 8, nicely displays the beta type.

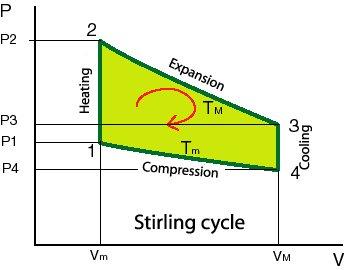

There are four parts to the Stirling Cycle:

1. Starting with the air in the hot cylinder, it is heated and expands thus pushing down both pistons and feeding energy into the flywheel.

2. The hot piston moves up forcing air to move into the

cold cylinder. Doing so gives up heat to the regenerator.

3. The air in the cold cylinder contracts so less

pressure is exerted on the pistons, which then move back.

4. The cold piston moves up, forcing air through the regenerator into the hot side where the cycle repeats.

This cycle is diagrammed in Photo 9. The cycle seems simple, but it involves complicated physics to make it all successful.

Thermodynamics is the science that describes the behavior of heat and energy. It is not attributed to any one person, but slowly evolved over hundreds of years. About 3000 BC, the Egyptians viewed heat as related to their myths. In 500 BC, the Greek Heraclitus proposed the "flux and fire" theory, stating that "All things are flowing." He had discovered the relationship between heat and energy. In the early 1600s, English scientist Francis Bacon proposed that heat is motion, hence energy. In his 1824 book, Reflections on the Motive Power of Fire, Sadi Carnot introduced the definition of work as "weight lifted through a height." In 1843, James Joule found the mechanical equivalent of heat. Then in 1850, Rudolf Clausius coined the term "entropy." The name, "thermodynamics" was coined in 1854 by British physicist William Thomson (aka Lord Kelvin) in his paper, On the Dynamical Theory of Heat. Thermodynamics had emerged into a real science.

There are four laws of thermodynamics that describe the

nature of heat and energy. For the purpose of this article, I will only

mention the first two, along with entropy. These principles are the ones

relevant to the Stirling Cycle.

FIRST LAW - Energy or heat can neither be created nor

destroyed in a closed system.

SECOND LAW - Energy or heat moves from a hotter area

to a cooler area in a closed system as entropy increases.

ENTROPY - Energy or heat expands from a localized area into a wider area. Hence, entropy always increases.

The British scientist C.P. Snow simplifies these first two laws. I just had to share this typical British humor that aids understanding:

First Law - You cannot win! (You can not get something for nothing, as matter and energy are conserved).

Second Law - You cannot break even! (You can not return to the same energy state because entropy always increases.)

Rev. Dr. Robert Stirling was a devoted minister and diligent engineer who gave the world a lasting gift. He cared for mankind, and so invented a device to make its life safer and easier. In return, the world seemed to ignore him. Although types of his engine are still being built today, he was not recognized for his ministry or for his inventive intuition. His grave in the small Galston cemetery fell into ruin and the headstone was broken and destroyed. Happily, he was honored in 2014 with a new headstone, as seen in Photo 10. He was also inducted into the Scottish Engineering Hall of Fame at that time. Two hundred years after his monumental patent, he received the honorable recognition that he deserved!

I certainly hope that the reader has enjoyed this introduction to the hot air engine, Robert Stirling, and thermodynamics. Next month, I will take the reader on a tour of the many fascinating types of hot air engines and their diverse uses: the ones that were built yesterday and the ones being built today. It will be an interesting journey.

Photo 1: Rider hot air engine

Photo 2: Portrait of Rev. Dr. Robert Stirling

Photo 3: Methven, Perthshire, Scotland ca.1920s

Photo 4: Diagram of Stirling engine as in the 1816 patent

Photo 5: Portrait of Sadi Carnot

Photo 6: Diagram of an Alpha type engine

Photo 7: Diagrams of Beta and Gamma type engines

Photo 8: DeLamater engine

Photo 9: Stirling Cycle on Pressure-Volume diagram

Photo 10: Stirling family headstone