April 2017

Turner Fricke

Part 2: The Machine

By Paul Harvey

Last month, I presented the story of the men who eventually produced the Turner Fricke engine: the conservative and industrious Harry C. Fricke and the flamboyant and reckless George Edwin Turner. Each had his own career and passion, and their differing personalities certainly seemed to complement each other. As the first article concludes, we find them partnered in the highly successful Keystone Engineering Company, producing electric light plants using the Walrath-designed Marinette gas engine. They electrified many buildings in Pittsburgh as well as throughout the country.

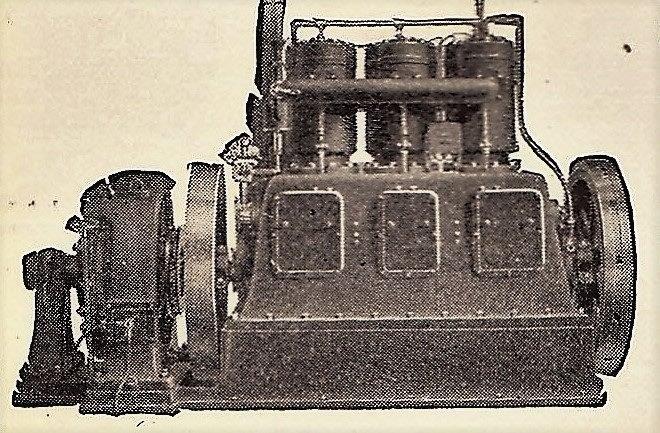

In 1905, Foos Gas Engine Company of Springfield, Ohio, purchased Marinette. This event seemed to have changed Turner and Fricke's entire future! However, Foos made very few changes to the engine and continued building it for many years. Note Photo 1. It is my speculation that Foos either terminated the Marinette contract with Keystone or raised the price of the engine enough that Keystone opted to produce their own engine. A brand new factory and engine would soon appear on the market!

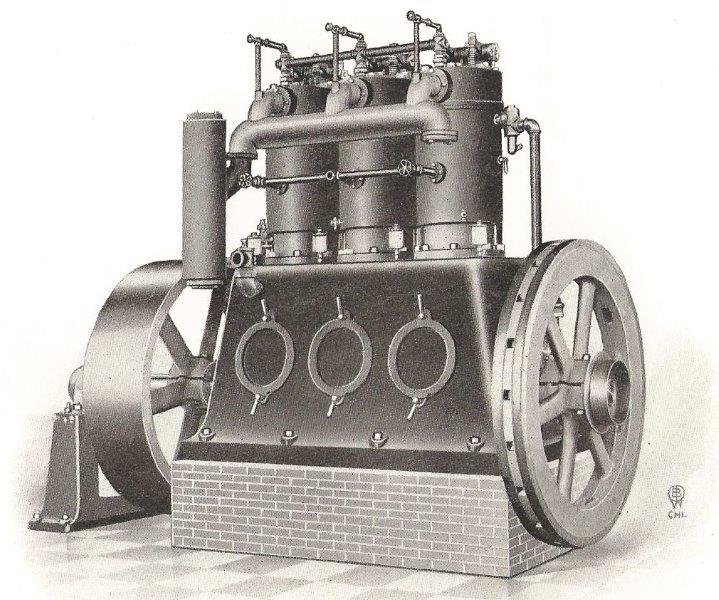

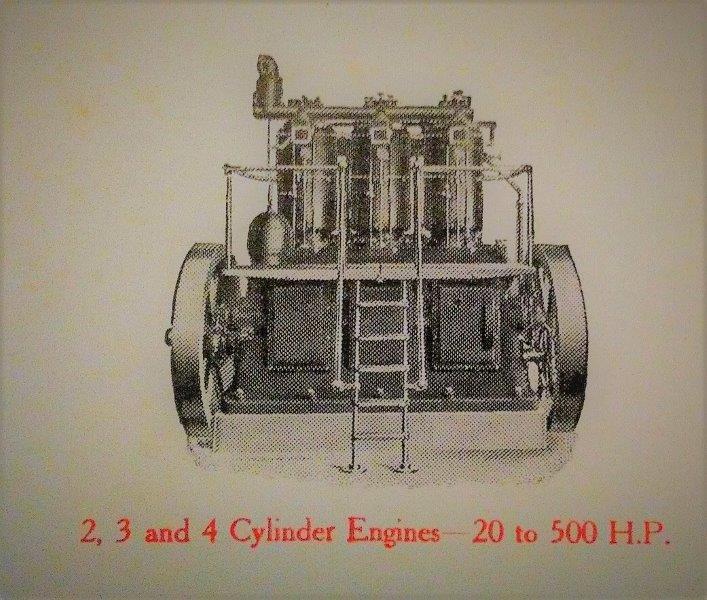

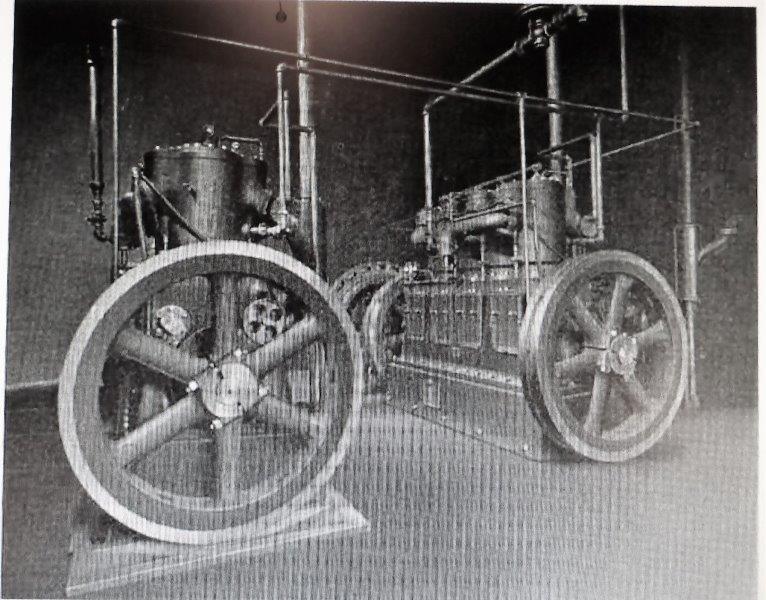

It is interesting to note the similarity of the Marinette engine, illustrated in Photo 2, and the Foos engine seen in Photo 3. The only apparent changes were enclosing the governor and relocating the mixer. Both featured graceful lines and overhead valves. In contrast, compare the Turner Fricke engine seen in Photo 4. It was much more massive and used the "T-head" design of valve placement. Apparently, Harry and George wanted their new product to be entirely different.

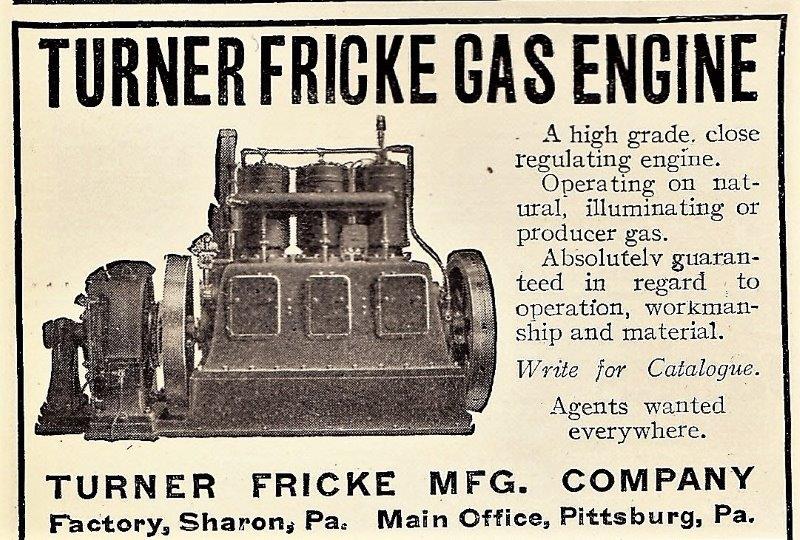

On February 18, 1907, the Pittsburgh Post Gazette announced the incorporation of the Turner Fricke Manufacturing Company to build gas engines and machinery. Then on June 21, 1907, the Philadelphia Inquirer noteed that Turner Fricke was building a new plant in Sharon, Pennsylvania, to produce their engines. At first this location seems unlikely, but there they would be close to Erie Foundry Company who would produce the castings, as well as having access to both lake and rail transportation. Perhaps they would also be away from the eyes of the competition as Westinghouse was producing similar engines in Pittsburgh. After some delays, the new plant was in operation in 1909. They now had a new engine to market!

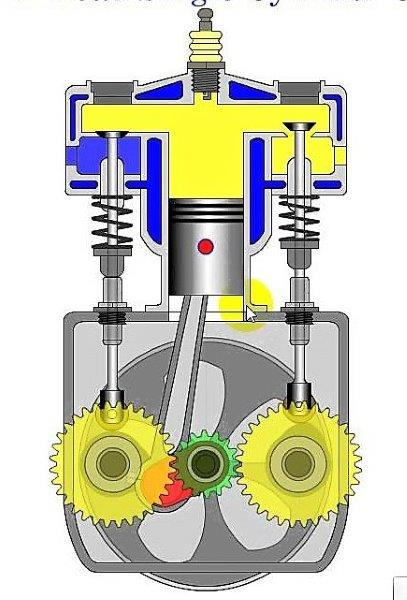

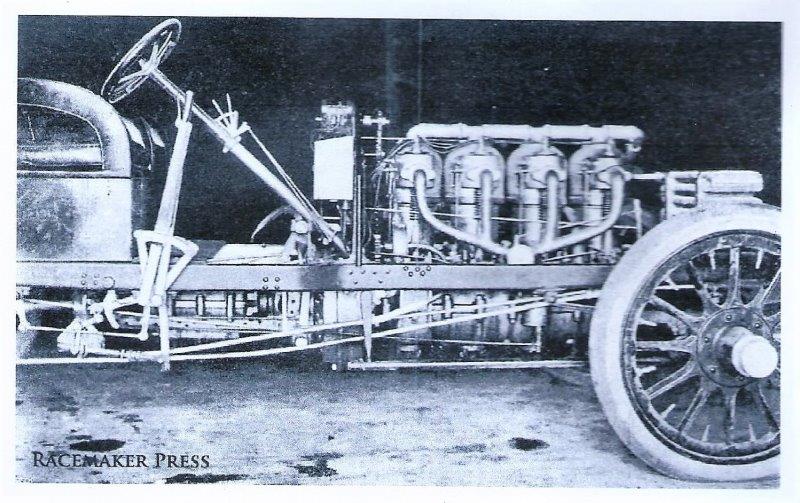

So why did they choose the T-head design, and what is it? A simplified diagram from the internet is seen in Photo 5. Clearly, the T-head can be seen, with valves on either side of the piston, and two cam shafts used to operate them. Although it was not as graceful as the Marinette or Foos, it did provide a very rigid design. Another consideration for this design was that George Edwin Turner was an avid automobile racer, always using the Peerless automobile. Peerless, as most other high class autos of that time, used the T-head engine. Note the 1904 photo of an early Peerless shown in Photo 6. This car was similar to Barney Oldfield's first Green Dragon, "the fastest car on earth." By 1909, note the magnificent engine in the Peerless Raceabout as illustrated in Photo 7.

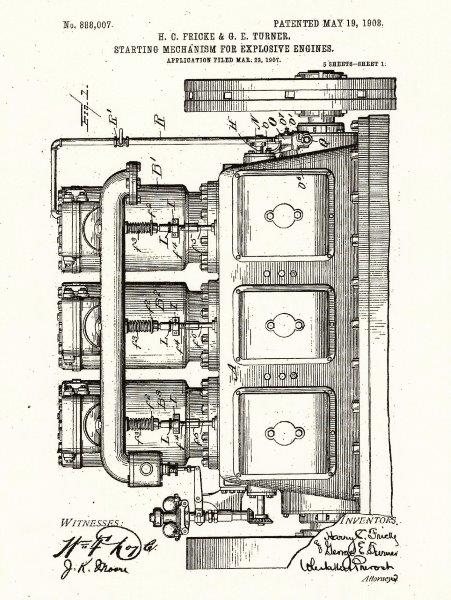

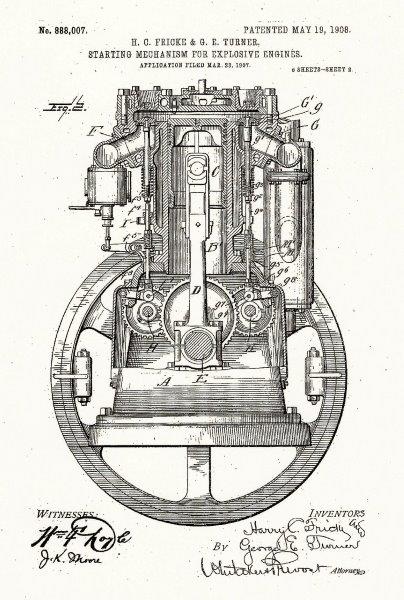

George Turner and Harry Fricke obtained three patents for their engine in the 1907 to 1909 era. It is unclear which person contributed more to the design, or if it was a mutual agreement. Turner was a graduate engineer, and Fricke was a self-taught engineer. One patent covered the base and adjustable main bearings, another concerned the valve design, and the third detailed the air starting system. For best illustration of the T-head design, I have chosen to illustrate patent number 888,007 which was granted on May 19, 1908. Although it featured the unique air starting system, the details of the engine can be seen in Photo 8 and Photo 9. They had created a massive and well built engine.

A 1910 Turner Fricke catalog describes engines from 25 to 325 hp, and equipped for either gas or gasoline. The single-cylinder engines were built to about 50 hp. In 1912, they had sales representatives in Cincinnati, Ohio; Chicago, Illinois; and Cleveland, Ohio. An interesting advertisement is shown in Photo 10. Note that this ad clearly states that the factory is in Sharon, Pennsylvania, and the office is in Pittsburgh, Pennsylvania. We see a typical unidentified installation in Photo 11, and Photo 12 illustrates one of the three engines in the Van, Pennsylvania, station on the United Natural Gas Company.

Business went well for many years but, following the deaths of Turner in 1923 and Fricke in 1925, the end was near. By this time, many cities and factories had access to commercial power, which eliminated the need for gas engine generating plants. The Pittsburgh Daily Post, on November 28, 1925, announced the terminating of the Turner Fricke Manufacturing Company. After 18 years, an era had ended!

However, there is a pleasant epilogue to the story.

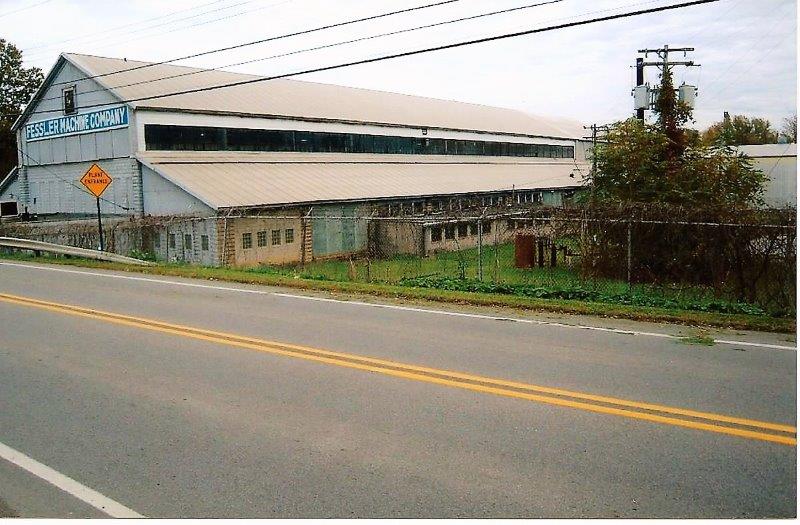

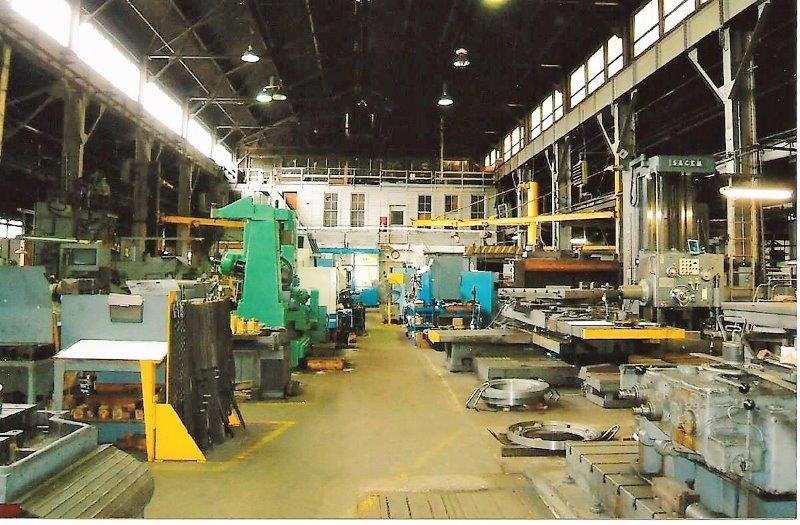

In 1937, Fessler Brothers bought the old factory to open a custom

machine shop.

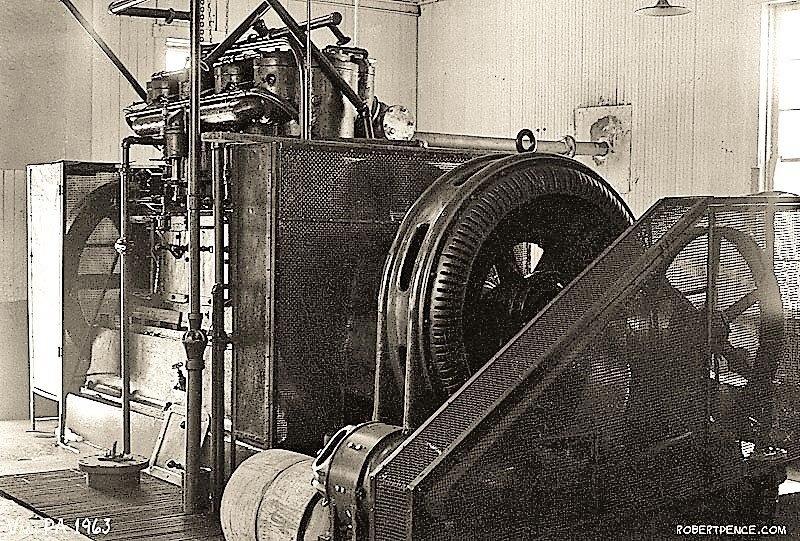

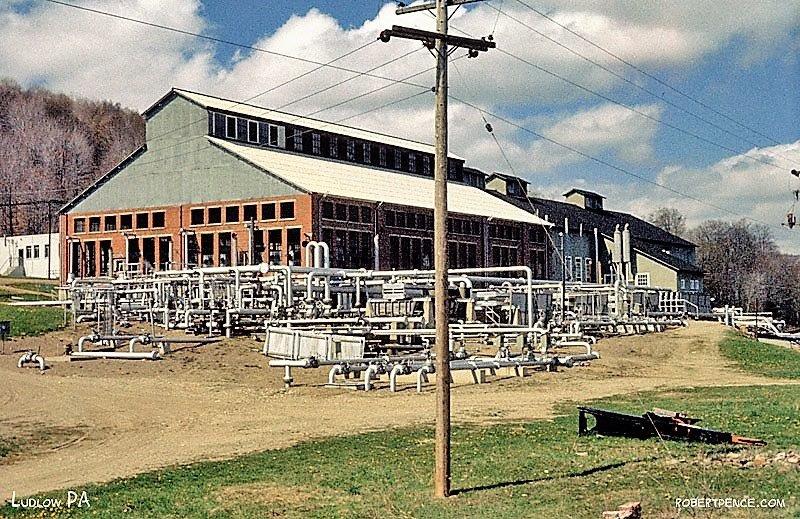

The Turner Fricke engine at Coolspring is a four-cylinder, 150 hp version that powered a 150 kva General Electric alternator. Originally, it and two other units provided power for Roystone, the majestic "queen" station of the Pennsylvania Gas Company which is now a division of National Fuel Gas Company. The electricity it produced was used for the station and all its accessories, as well as for the six company houses. View the 1963 image of Roystone as Photo 15. It is all just a memory now. Photo 16 is a recent photo of the red tile Turner Fricke power house. At one time, it housed the three great engine generator sets, and had an entire wall of white marble panel boards that contained switches and meters. The power house is now a truck garage.

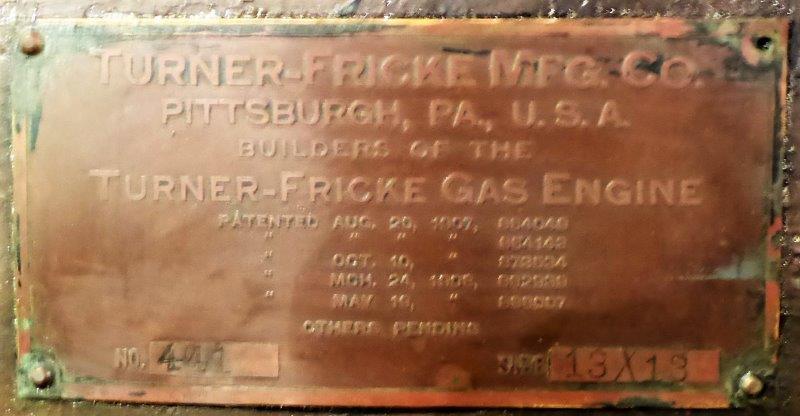

In 1971, I removed one Turner Fricke engine from Roystone and brought it to Coolspring. At that time, I could have gotten any other items from Roystone. Photo 17 shows how the engine appears today. Our engine has a 13 inch bore and 13 inch stroke, producing 150 hp at rated speed of 277 RPM. This speed allows the alternator to produce 60 cycle alternating current. Its nameplate is seen in Photo 18. Note the serial number of 441, which seems to have been stamped again. Roystone Station did not have any record of the installation date, so the exact vintage is unclear.

The alternator that I chose was not the one this engine originally operated. Note Photo 19, showing the different coupler sizes. However, this machine was much more massive and detailed than the original. The large "V" belt pulley drove the exciter. This configuration is seen in the Van engine photo. I was able to save a few of the white marble panel boards which are shown in Photo 20.

Being a T-head design, the engine has two cam shafts, parallel to the crank shaft, that extend through the crankcase. This design readily provided four accessory drives that were well used. One of the drives turned the battery timer, providing power to a box of four Ford Model T buzz coils. The coils provided energy to one set of spark plugs. It is shown in Photo 21. Two items shown in one picture are the high bar KW magneto, which powered the other set of spark plugs and behind it is the governor head, which regulates the amount of air and gas entering the engine, hence controlling its speed. See Photo 22. The last drive powers the patented air start cam, as depicted in Photo 23. When starting, the middle two intake valve push rods are slid forward, so not to operate the valves, and both middle cylinders then receive air on every revolution to promote starting. Our engine proves it works very well.

It is my desire that the reader has enjoyed this article about the Turner Fricke gas engine, as well as last month's article detailing the lives of the inventors. Please visit the museum to see the majestic Turner Fricke engine in operation.

Photo 1: Foos Engine catalog

Photo 2: Marinette engine

Photo 3: Foos engine

Photo 4: Turner Fricke engine

Photo 5: T-Head engine cross section

Photo 6: Peerless automobile ca. 1904

Photo 7: Peerless Raceabout

Photo 8: Patent drawing showing engine layout

Photo 9: Patent drawing showing engine cross section

Photo 10: Ad for Turner Fricke

Photo 11: Typical Turner Fricke installation

Photo 12: One of three Turner Fricke engines at Van station

Photo 13: Fessler Machine Company exterior

Photo 14: Fessler Machine Company interior

Photo 15: Roystone Station in 1963

Photo 16: Roystone's former power house

Photo 17: The Roystone Turner Fricke now at the museum

Photo 18: Turner Fricke nameplate

Photo 19: Alternator with the Turner Fricke

Photo 20: Panel board

Photo 21: Battery timer for ignition

Photo 22: Magneto and governor

Photo 23: Air start cam