February 2017

Three Cousins

By Paul Harvey

I have had a long-time fascination with the large, heavy, and sometimes crude oil field engines. As I live at the eastern edge of the Pennsylvania oil field, they were the first large engines that I saw. Being privileged to witness many in operation, I was even able to discover the factories where they were made. Occasionally I would find an interesting four-cycle engine, but the main work force used to pump the oil wells was the two-cycle design. These engines were both the "half-breeds," which were steam engines converted to gas engines, as well as the factory built two-cycle engines. This design was produced by many different makers, and all seemed to be similar. Basically, the two-cycle engines were simple, sturdy, and dependable.

As time progressed, three two-cycle engines stood apart from the others. I noted these to be similar in design, as well as being very heavy and rugged. They were able to be moved through the oil field by teams of horses for use on distant wells, and then operated the wells for long hours. They were not patented, and all three emerged in the 1905 - 1906 era. This was the time of the oil boom in Pennsylvania, West Virginia, and Ohio, and the demand for engines was great. These "Three Cousins," as I have called them, are the JC, built in Titusville, Pennsylvania, the South Penn, built in Clarksburg, West Virginia, and the Ball, built in Butler, Pennsylvania. Photo 1 shows the museum's three examples lined up in Paul's Pavilion, our new exhibit space. The similarities are remarkable. There just had to be a link connecting these designs!

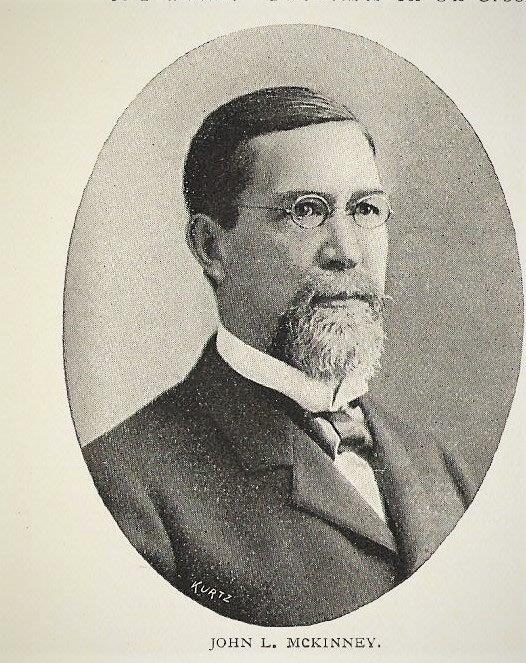

After some research, I found that the link was the McKinney brothers. They were born near Warren, Pennsylvania, and became wealthy in the oil business at an early age. James Curtis McKinney moved to Titusville, Pennsylvania, and became president of the Titusville Iron Works; hence the name for the JC engine. John Luke McKinney became involved with South Penn Oil Company and soon became president. Henry B. McKinney moved to Butler, Pennsylvania, and quickly became president and manager of the Butler Engine and Foundry Company, makers of the Ball engine. It was a family affair!

The JC Gas Engine

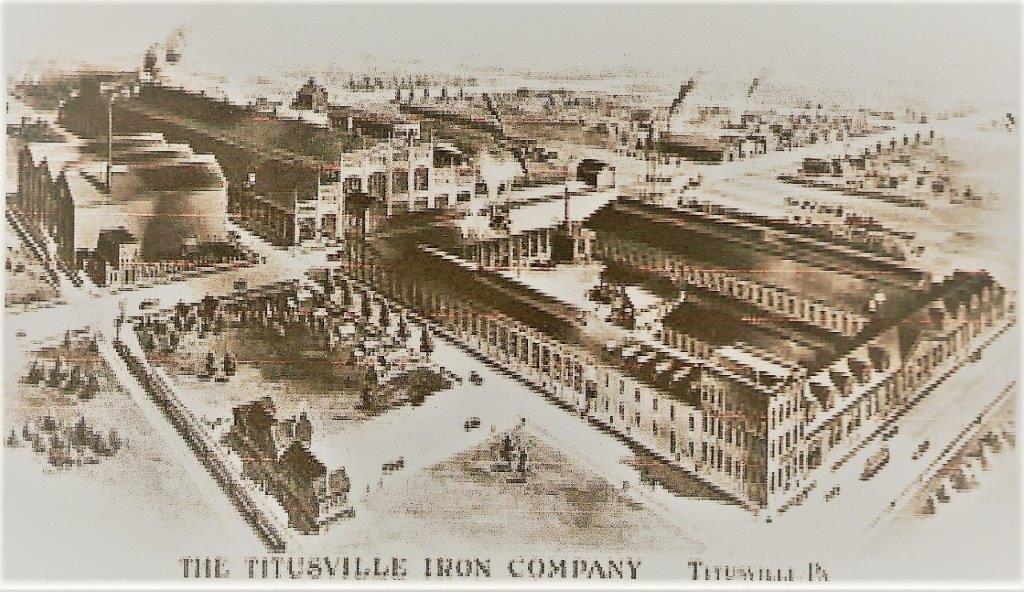

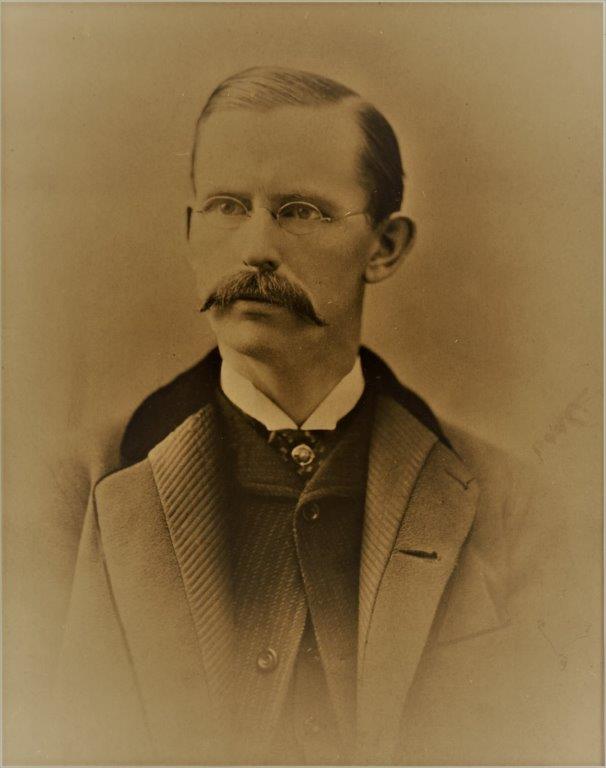

The Titusville Iron Works developed into a large concern with the early oil frenzy in that area. Note Photo 2. Under the capable leadership of J. C. McKinney, Photo 3, the firm was a major manufacturer of the Olin four-cycle gas engine, licensed from the Buffalo, New York, firm that had patented it. All the majestic, octagonal South Penn powerhouses used Olin engines and Titusville Pumping Powers. The engines were on concrete foundations which bore the initials in large relief, SPOCO, or South Penn Oil Company. This was further proof of a tie between Titusville Iron Works and South Penn.

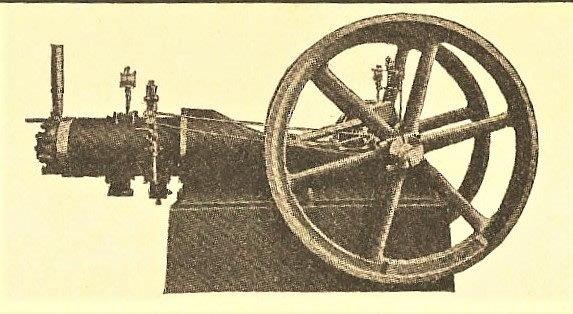

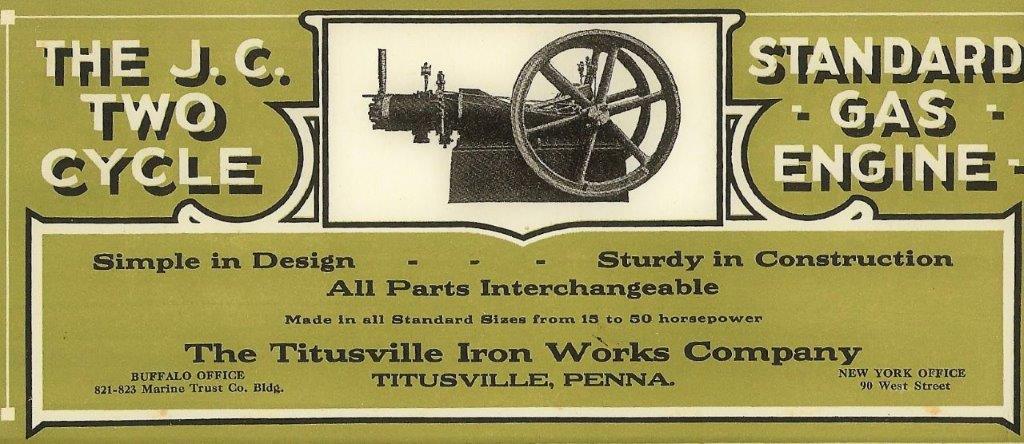

Probably feeling the pressure from a major two-cycle engine builder, the Bessemer Gas Engine Company, McKinney produced his own two-cycle design, named the JC. This engine was apparently designed "in-house" by the Titusville Iron Works. See Photo 4. Appearing in 1906, these engines were built from 15 hp to 50 hp. Soon, many were found pumping oil wells in Pennsylvania, West Virginia, and Ohio. The JC engines were very durable and could withstand the use and abuse of the oil field. A factory advertisement is shown in Photo 5.

While attending West Virginia University in the late 1960s, I became acquainted with an oil pumper, Les Neely. Skipping class, I spent many enjoyable days with him learning about the engines and the art of pumping oil. The first large engine he taught me to start, operate, and care for was a JC! The next one was a South Penn.

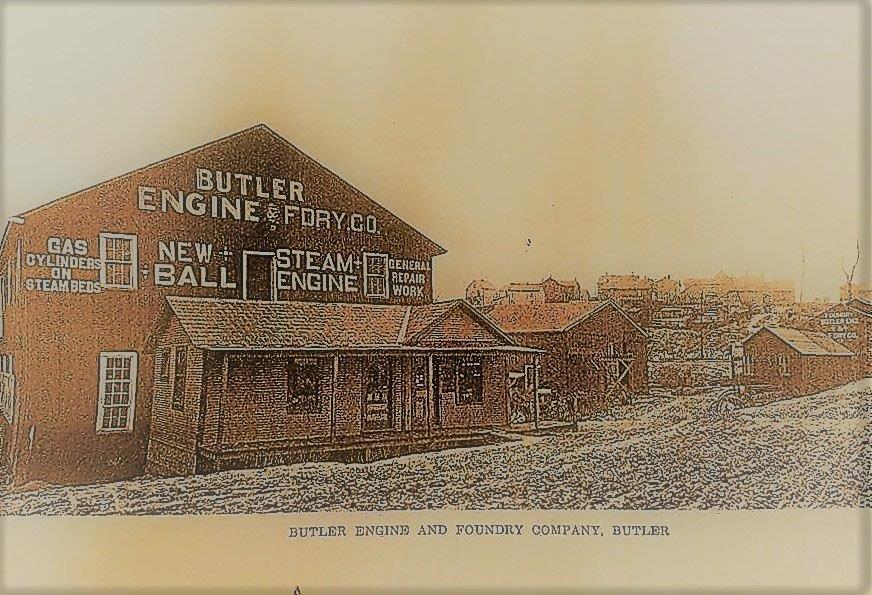

The Ball Engine

The Butler Engine and Foundry Company was one of the earliest engine makers in that city. Note Photo 6, which shows their early shop. With the oil boom in that area, the firm licensed the design of the Ball steam engine, which was built in Erie, Pennsylvania. At that time steam was very popular for drilling the wells, and, later, the engines could be easily converted to gas engines. Under the capable command of Henry B. McKinney, Photo 7, the firm was soon the leading manufacturer of gas engines in Butler, PA. The foundry also made casting for many other engine producers. Soon, all of their engines, gas and steam, were named "Ball, an easy name to remember. That name soon was well known throughout the oil field.

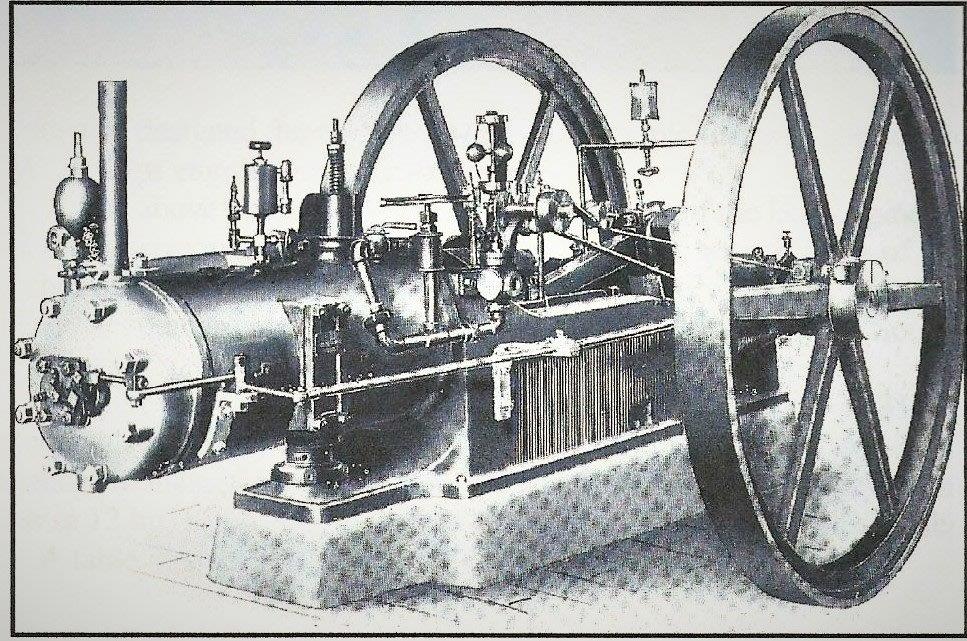

About 1906, the firm decided to produce its own design of two-cycle gas engines. The Ball was built in sizes from 12 hp to 35 hp; a 25 hp version is shown in Photo 8. This engine is very similar to its two other cousins but does bear features of being built in Butler. If nothing else, the horizontal mounted telegraph wheel throttle and flywheel design betrays its origin.

The Ball engine sported a crosshead-operated water pump, which the JC also used. This was very unusual in gas engines. Another interesting feature was the star wheel electric igniter. Similar to Bessemer's igniter, this design was patented by Arthur Clark, who also designed the unusual uniflow cylinder for the T. W. Phillips engine. The proliferation of ideas is truly amazing.

The Ball two-cycle gas engines, heavy and durable, soon were used in the oil fields of Pennsylvania, West Virginia, and Ohio. They proved to be very dependable

South Penn Gas Engine

The South Penn Oil Company was organized by Standard Oil in 1889 to be its sole crude oil production facility in the Appalachian oil fields. The headquarters were located in Oil City, Pennsylvania. Both with mergers and newly discovered oil fields, South Penn became the largest producer of crude oil in the United States by 1898. After the break-up of Standard Oil in 1911, South Penn was organized as an independent oil producing firm and continued to grow. Soon the headquarters were moved to Pittsburgh, Pennsylvania.

In the early 1900s, large oil deposits were discovered in West Virginia, and South Penn, in competition with Hope Oil and Gas Company, leased thousands of acres to drill and develop. While Hope drilled its wells sporadically, South Penn meticulously laid out 600 foot squares and drilled their wells at each corner, no matter what the terrain was like. Hope used Pattin Brothers and Reid engines, while South Penn decided to use their own.

At this time John Luke McKinney, Photo 9, was president of South Penn. It seems that he could have used either the JC or the Ball that his brothers manufactured, but transportation was difficult and expensive then. Although details are sketchy, it seems that he decided to make a similar design locally. I have been unable to find engine details or shop photos, so some of the comments are my own conjecture.

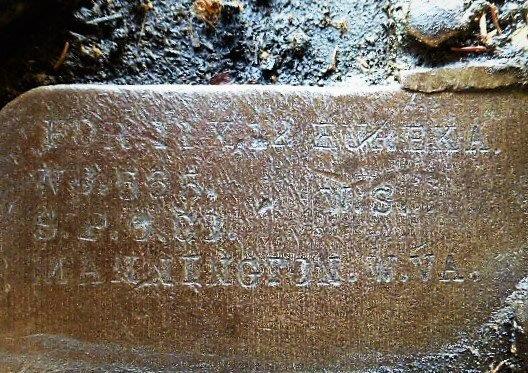

Some records suggest that the first South Penn shops were located in Mannington, West Virginia, and there they produced a convertible gas and steam engine. The example displayed at Coolspring is shown in Photo 10 and has the Mannington location stamped on it. Although difficult to read, note the stamping as seen in Photo 11.

It seems that the Mannington shops were phased out in the early 1900s, and new, huge, brick shops were built near Clarksburg, West Virginia. Here they manufactured engines, boilers, and all kinds of oil field equipment to be used in the oil boom nearby. Presumably, the South Penn two-cycle gas engine was designed and produced at this location. It was built in only two sizes, a 20 hp and a 25 hp. The larger size had a cylinder bore one inch wider than the smaller.

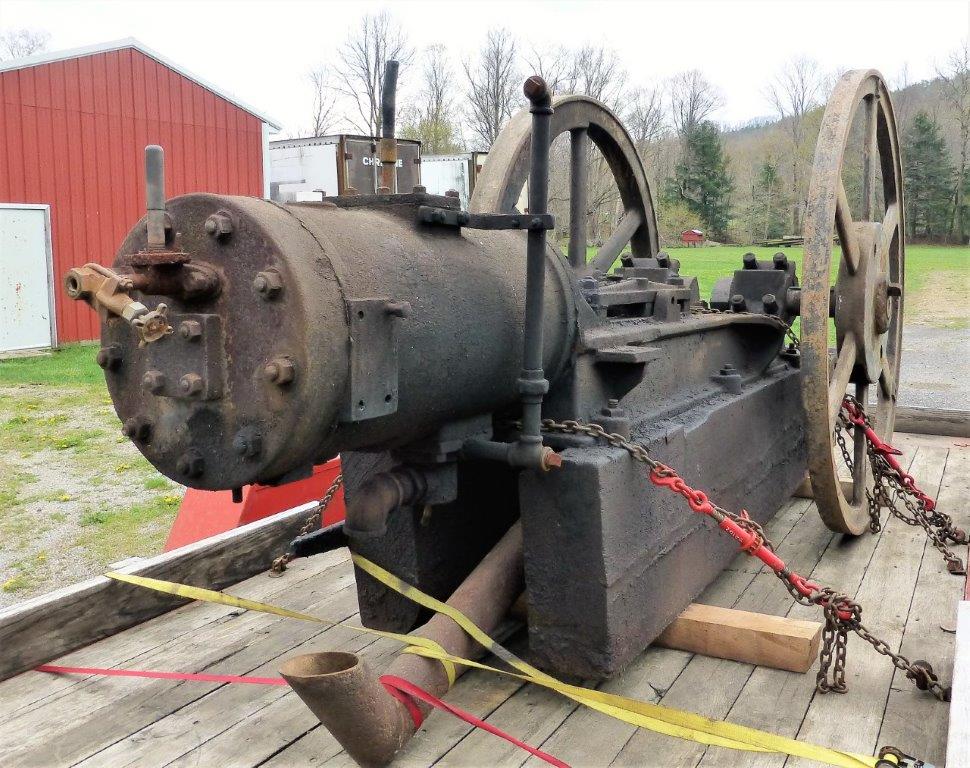

Unable to find a factory photo of the South Penn, I chose to illustrate Coolspring's engine shortly after it arrived here. Note Photo 12. We are fortunate to have a copy of the well drilling log which indicates that this engine arrived new, in 1916, to Dutchtown, West Virginia, to drill and pump the well named Haught #10. This number meant it was the tenth well that South Penn drilled on the Peter Haught farm. Peter Haught was an immigrant from Holland. The engine spent 99 years on that steep hillside! Photo 13 shows the Haught #10 well, engine still inside, when I was guided to it in the spring of 2013.

The last mystery is the South Penn Special which could have been either a "half-breed" or a factory built engine. It uses the South Penn cylinder with their own heavy flywheel on the clutch side, and these parts were assembled onto a new steam engine frame. The demand for engines was very urgent and, by choosing the very heavy Oil City Boiler Works frames, they could quickly make more engines. Note Coolspring's South Penn Special, shown in Photo 14, on my trailer ready to come home. This engine now runs beautifully!

With little supporting information, it is my opinion that the South Penn shops were overwhelmed with the demand for engines. The production could be increased by purchasing new Oil City Boiler Works steam engines without the cylinder. South Penn, by adding their own cylinder, heavy flywheel, and clutch, would have another source of new gas engines! Any comments or information will be appreciated by the author.

It is my sincere hope that the reader has enjoyed this introduction to the "Three Cousins". They can be seen by visiting the Coolspring Power Museum. Perhaps someday, I will be able to find enough information to write a complete article on the South Penn engine.

Photo 1: JC, South Penn, and Ball - the "Three Cousins" displayed in Paul's Pavilion

Photo 2: Titusville Iron Works

Photo 3: J.C. McKinney

Photo 4: The JC engine

Photo 5: Factory ad for the JC engine

Photo 6: Butler Engine & Foundry Company

Photo 7: Henry B. McKinney

Photo 8: The Ball engine

Photo 9: John Luke McKinney

Photo 10: Mannington convertible engine

Photo 11: Nameplate for the Mannington convertible engine

Photo 12: South Penn engine

Photo 13: The Haught #10 well in 2013

Photo 14: South Penn Special engine