|

August 2016

June Show Report

By Paul Harvey

The June 2016 Engine Show was perfect! The weather was great and,

despite a shower after dark, we did not have the usual mud and dismal

skies. Everyone seemed relaxed and happy to enjoy the engines they

exhibited in the show areas and also happy to enjoy all the museum's

engines. There was plenty of good food and a great flea market. I hope

such a great experience can happen again.

Our theme this year was "One-of-a-Kind Engines," and so many were

exhibited here. I certainly learned a lot by seeing machines that I had

never been aware of before. The engines exhibited in the show field

represented many unusual and unique designs. It was a joy to tour.

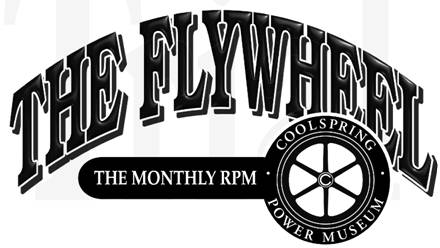

Proceeding with the photo tour of the show, Photo 1 shows

Steve Tachoir's 30 hp Olin placed in the new engine pavilion. This was

the first engine installed there. It is a beautiful, old style Olin and

now runs. It had been a static display on the front side of the John P.

Wilcox Power House for about 40 years. The original location was a

South Penn oil lease near Warren,

Pennsylvania. Reportedly, it last ran in 1967.

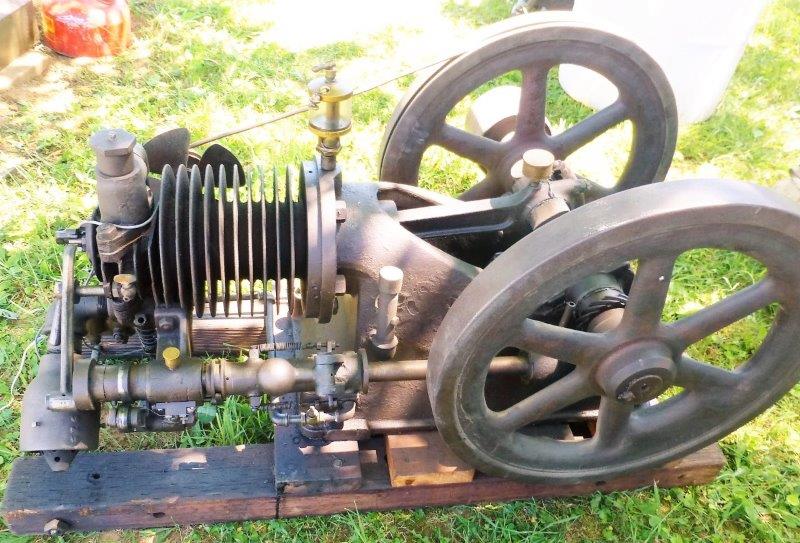

Photo 2 shows Chris Austin's 20 hp Bradford Improved

engine still waiting to be unloaded and operated. Built by the

Combination Engine and Compressor company of

Bradford, Pennsylvania, it

is the only one existing. It is a four-cycle engine with an enclosed

crankcase and pendulum governor. Most unique, it is a straight engine,

without the compressor cylinder, and operated a rod line pumping power

just north of Bradford, PA.

A little vertical engine, built by the American Motor Company

of New York City, is seen in

Photo 3. Manufactured in the 1890s, it features a unique

"V" arrangement of the valves. Rated at one horsepower, it weighs a

mere 50 pounds. Air cooling was accomplished with wire wrapped around

the pegs on the cylinder. It is based on the 1889 patent of Lyman

McNeth, number

407,961.

Don Worley always brings a pleasant surprise and this air

cooled, old style Jacobson was no exception. Note Photo 4.

Its precision cylinder fins for air cooling are actually cast and

not machined. It has the side shaft governor and electric igniter.

Homemade "one-of-a-kinds" are always interesting, as Vince

Barber proves with his engine. Shown in Photo 5, it

features a very long and graceful connecting rod, and is a joy to watch

run. Looking closely, I can see pipe fittings and other items found

around his shop. Creativity was certainly the beginning of the gas

engine.

Photo 6 is a massively built engine identified

as The Michigan. Displayed by Bob and Steve Upham, it has graceful

curved lines on the head and valve chest. It runs, nicely of course,

hit and miss with an electric igniter. A placard denotes that it is

shown in memory of Richard Doty.

Most of us are familiar with the Bates and

Edmonds line of engines, made in

Lansing, Michigan. But

this one, Photo 7, owned by Woody Sins, is most

unusual. It has an overhung power cylinder and flywheel crank shaft.

Many familiar features are seen on close inspection. It actually makes

sense, being a compact design for small power applications. Most all

parts are easily accessed for repair and adjustment.

Stiles Bradley brought his diminutive 1½ horsepower,

inverted Webster, as seen in Photo 8. It features two

sets of timing gears, one to operate the exhaust valve, and the other to

power the igniter. It ran great and attracted a lot of attention.

Photo 9 is a squat little engine that has to be

described as "cute." It is four-cycle and made as a stationary engine,

but has the appearance suggesting marine usage. It was built by Gleason

& Bailey & Sciple of Seneca Falls,

New York. Yes, the name plate has an "&"

between each name! Note that the head, cylinder, and base are all one

casting. A machinist's nightmare!

Charles Stickney built many unusual engines and Photo

10 is no exception. This little engine was built to power a

water pump; notice the forked rod that lifted the well plunger up and

down. It features an overhung cylinder and all the complicated valve

motion that was typical of Stickney. Note the gasoline tank is mounted

on the very top of the engine.

This amazing tractor, Photo 11,

was displayed by Nick Rowland and his dad, Ed. Built by the

Sexauer Brothers of Sulfur Springs, Ohio, it shows both extremely crude,

as well as very sophisticated, design. Circa 1904, its main use was to

buzz saw wood. It could easily drive to the location of the saw, do its

work, and then drive back home again. Fortunately, they found it

preserved in a corn crib where it had rested for many years. The engine

is Sexauer's own design and features desmodromic valve motion; meaning

that the valves are both opened and closed under power. Ignition is by

a Goodson magneto and plug, and it operates beautifully.

Photo 12 is an engine with an oscillating

cylinder to permit the intake and exhaust functions. Displayed by Dave

Deardorff, it is absolutely fascinating to watch run, with the cylinder

oscillating back and forth in its mountings. This design was used in

steam engines, but never before have I seen it in gas engines. It was

made by Henry Philomen LaTour of Copper Cliff,

Ontario, Canada,

for marine use.

The Lutz opposed piston engine is shown in Photo 13.

It was built by Thomas J. Lutz of Mansfield,

Ohio, as a model to obtain his 1906 patent. It

appears crude at first glance, but it is very intricate and operates

beautifully. He did obtain the patent but never produced any of the

engines for sale. This one powered his small machine shop faithfully

for many years.

Photo 14 depicts a single-cylinder Caterpillar

test engine built in 1938. It is displayed by Gene Shepherd of

Shelter Island, New York.

The engine is single-cylinder with a 5¾ inch bore and 8 inch

stroke producing 25 hp at 900 RPM. Major companies commonly built test

engines to try their new designs, but they were usually scrapped after

the testing to prevent the competition from using them. It is great

that one has survived and lives again.

Although not a "one-of-a-kind," a shingle mill always is

popular with our guests. Photo 15 shows Phil St. Jean

chatting with a couple of visitors while standing behind his 1912 Chase

Shingle Mill. Built in Orange,

Massachusetts, these amazing machines cut

tapered wooden shingles from pieces of logs. Phil made several hundred

shingles during the show. To the right is 15-year-old Denali John who

is branding each shingle with the Coolspring Power Museum logo. The

branding iron must be reheated in the propane furnace for each shingle!

The mill is powered by my 1952 John Deere "R" diesel tractor. Branded

and milled shingles were available to the visitors for a $1.00 donation.

Photo 16 shows a nice little 4 hp engine that

was labeled as "unknown." I had no idea of its identity, either. It is

a vertical with a rounded but open crankcase and hit and miss governor.

Since then, it has been identified as a Witte vertical made for them by

the Star Mfg. Company. I am still looking for more information.

"The Earl" is a very pleasantly proportioned side shaft

engine with a vertical governor. It is shown in Photo 17.

It was built by the Earl Machine Works of

Burlington, New Jersey.

Noted as 6 hp, it is serial number 37. I wonder how many were built?

An unusual four-cylinder marine engine is seen in Photo

18. Displayed by Dieter Lund, it was built by the Standard

Motor Construction Company of Jersey City,

New Jersey. It has a unique valve motion, as

well as electric igniters. Note the reversing clutch on the left side.

Standards are very rare, and this is the first large one that I have

seen.

This beautifully restored Dodge Power Wagon brings back

memories of the trucks used in the former days of the oil field. See

Photo 19. Indeed, this one is owned by Ray and Linda

Stiglitz of the Pembrooke Oil and Gas company. It look like it is ready

to work in all the mud and grease!

Finally, Photo 20 shows a little engine

displayed by Ron McClellan. It is designed to operate as a steam engine

or a gas engine. Initially thinking that it was built by Riddle Machine

of Claintonville, Pennsylvania, I have since found a patent that it is a

Victor Palm from Butler,

Pennsylvania. It now resides in Coolspring and

it will be interesting to further investigate its history and operation.

I hope the reader will enjoy this tour of Coolspring's 2016

June Show and a few of the great engines displayed. There were so

many more.

Next month, we will tour back memory lane to view some

of the late Dr. John Wilcox's early photos. Recently converted to

digital format, they will bring back many memories.

|