July 2016

Museum Progress

By Paul Harvey

After a relatively mild winter, all the volunteers were eager to awaken the museum and hear some engine noise at our season's opening in April. There were many new projects to start, as well as old ones from last year to complete. With the nice weather, the enthusiasm was tremendous! The progress continued throughout the May Open Weekend and right up to the show. It is truly amazing how much has been done. For those who were unable to attend our June Expo, I have included photos of some of the projects completed during that time. It is my hope that you will enjoy this photo essay.

Photo 1. The 10 horsepower Schleicher-Schumm slide valve engine, which was displayed in its trailer last year, now lives in the Preston Foster Hall at the museum. Shown in the photo are Mike Monnier, in the trailer, and Al Grenning placing the planks to unload it. It is perhaps the largest of such engines known, and runs beautifully.

Photo 2. The engine is now in its final display site and piped up to operate in the building. When this engine was found many parts were missing, and Wayne Grenning meticulously manufactured the parts to return it to its original condition.

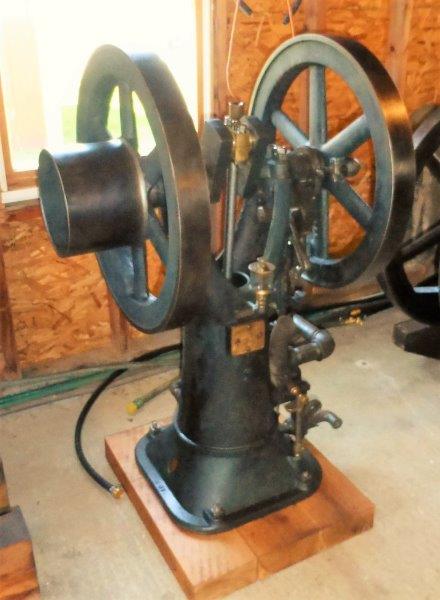

Photo 3. Last fall, Steve Tachoir took the 2½ hp

inverted Webster engine home for a total restoration. It has lived in

the Founder's Engine House for so many years as a static display. He

removed all the old paint, which revealed the original deep green

color. It is now back in place and operational. This engine originally

pumped a single oil well near Van,

Photo 4. Another static engine from the Founder's Engine

House is the S.M. Jones combination engine and air compressor. Museum

volunteer Doug Allen spent the winter on its restoration, and it is now

proudly operational. Built in

Photo 5. In order to provide better access to the Gotschall Food Pavilion, a new sidewalk was built. It extends along the pavilion and out to the driveway to make wheelchair access easy. Our volunteer Rob Northey engineered the project. The museum staff is enjoying lunch in the pavilion long before the concrete is dry.

Photo 6. Rob Northey has worked hard on the General

Electric engine and generator. It is now thoroughly cleaned and placed

in a prominent display position in the

Photo 7. The Farrar & Trefts steam engine by

Photo 8. The walking beam and pitman arm were set in place in the next month. We see a very happy Rod Fielder admiring all his hard work and design as Jonah Close operates the steam engine. It is so pleasant to watch the beam slowly and smoothly go up and down about 20 times a minute. Now the imitation well head and pumping rod will be completed.

Photo 9. Here we see Jonah Close starting the eight

horsepower Etna engine. It originally powered the second J.P. Berry

Shop in

Photo 10. Last fall the decision was made to build a new

engine pavilion to house the oil field engines that are located in

several different areas. Many are outside. After deciding to locate the

32 foot by 104 foot structure between the Exley Station and Pat's Place,

we found that we had a huge brush patch to clear. The photo shows Steve

Wolbert's little

Photo 11. Here we see the pavilion nearing completion. Engines will be placed during the summer, and some should be operational for the fall show. It will be a great display, and it complements the area.

Photo 12. Our new member Steve Wolbert has a love for trucks and construction equipment. Here we see his newest addition, a heavy duty, vintage Diamond Reo. It has the big gas engine coupled to a five-speed transmission with a four-speed auxillary. He has been working diligently on it and already has a dump body to install. It will be the museum's big dump truck.

Photo 13. During the May Open Weekend, we hosted a Girl Scout tour of the museum. In this photo, we see our capable tour director, Terry Smith, explaining the Fuller and Johnson pump jack engine that is located on the old water well behind my house. With limited time for his presentation, he chose engines that operate for a purpose which can be related to present time. His tour was a big success.

Photo 14. Mark Himes has the line shaft installed in the Bob Himes Ice Cream Shoppe. When completed, it will simplify engine and freezer placement. It will add more spectator interest to see all the flat belts operating.

Photo 15. Doug Fye and Reid Wellman, engineers for the 150 hp Miller engine project, now have the flywheel pit completed. They also have the floor of the exhaust pit concreted. After the walls of the exhaust pit are completed, they will concentrate on pouring new babbitt main bearings. Progress is well ahead of schedule.

Photo 16. Nate Smith has worked hard to complete the cooling water system for the Coolspring Municipal Works building. The big steel tank now provides cooling water from a gravity head to all the engines inside. The water then returns to a concrete sump tank, from which it is pumped back to the steel tank for reuse. Note the octagonal concrete foundation for the steel tank.

Photo 17. Steve Tachoir installed this new display in the Founder's Engine House. The maker of the hopper cooled engine to the left is unknown, but it is a very interesting machine. The Webster (in the center) and the Jones (to the right) have been mentioned above. Very soon all the engines in the Founder's Engine House will be operational.

Photo 18. Ben Egloff now has half the floor concreted in

his Type X Bessemer display building. This big 80 hp engine provided

compressed air to pump oil wells near

Next month, The Flywheel will review the June show. It featured "One-of-a-Kind" engines so there should be some great photos.

Remember our July Open Weekend on Saturday, July 16, and Sunday, July 17. Saturday, only, will feature History Day and the Antique Car, Truck & Tractor Show. There will be food available as well and plenty of staff to explain the engines. It is a relaxed and enjoyable day for all. So, bring your vintage car, truck, or tractor for display and enjoy the day with us.

Photo 1: Unloading 10 hp Schleicher-Schumm engine

Photo 2: Schleicher-Schumm engine in Preston Foster Hall

Photo 3: Restored Webster engine

Photo 4: Restored S.M. Jones engine-compressor

Photo 5: New sidewalk at the Gotschall Pavilion

Photo 6: GE engine and dynamo

Photo 7: Setting the sampson post

Photo 8: Farrar & Trefts engine and walking beam

Photo 9: Jonah starting the Etna engine

Photo 10: Lorain shovel clearing brush

Photo 11: New pavilion nearing completion

Photo 12: Vintage Diamond Reo truck

Photo 13: Terry Smith giving Girl Scouts a tour of the museum

Photo 14: New line shaft in the Bob Himes Ice Cream Shoppe

Photo 15: Flywheel pit for the 150 hp Miller engine

Photo 16: Cooling water system for the Coolspring Municipal Works exhibit

Photo 17: New display in the Founders Engine House

Photo 18: New concrete floor for the Bessemer Type X