February 2016

The DuBois Story - Part 2

By Paul Harvey

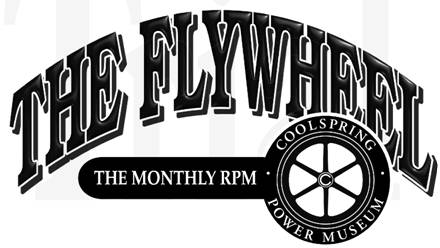

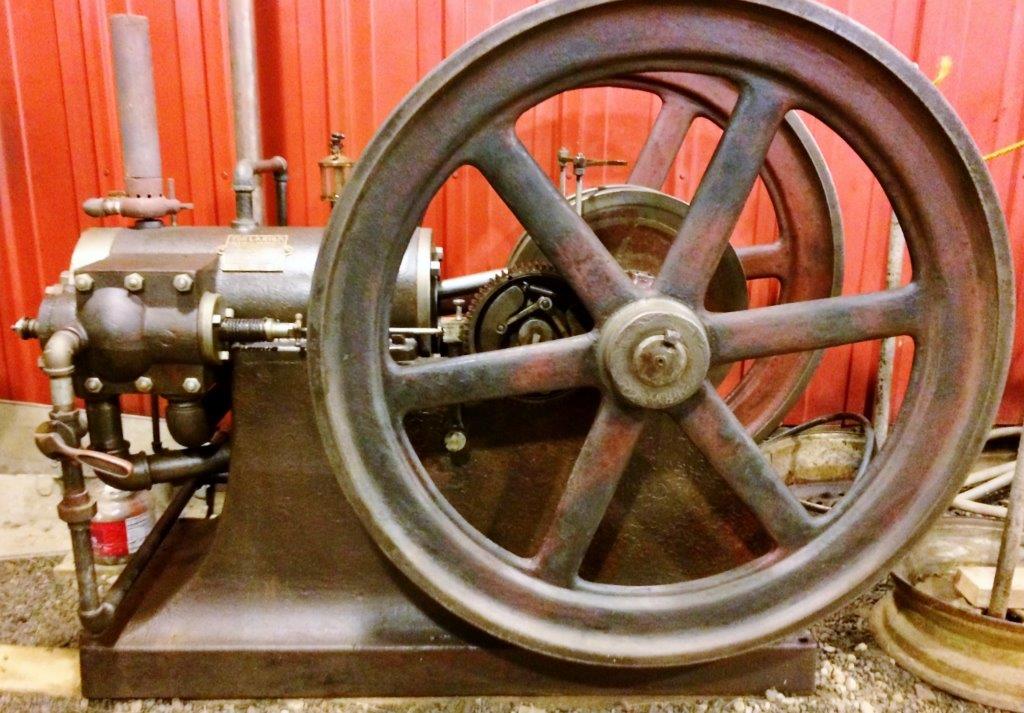

Coolspring Power Museum's 18 hp DuBois engine

Last month, The Flywheel

explored the early history of the city of

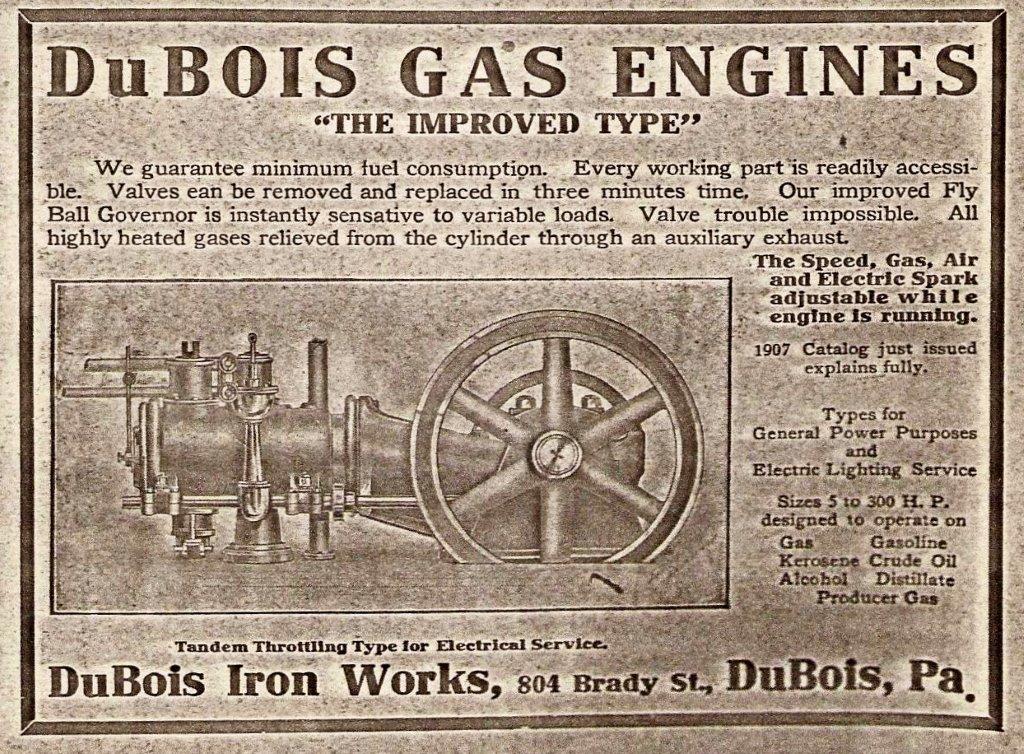

The earliest advertisement for the DuBois

Iron Works that I discovered is shown in Photo 1.

Appearing in the New Bethlehem Vindicator on

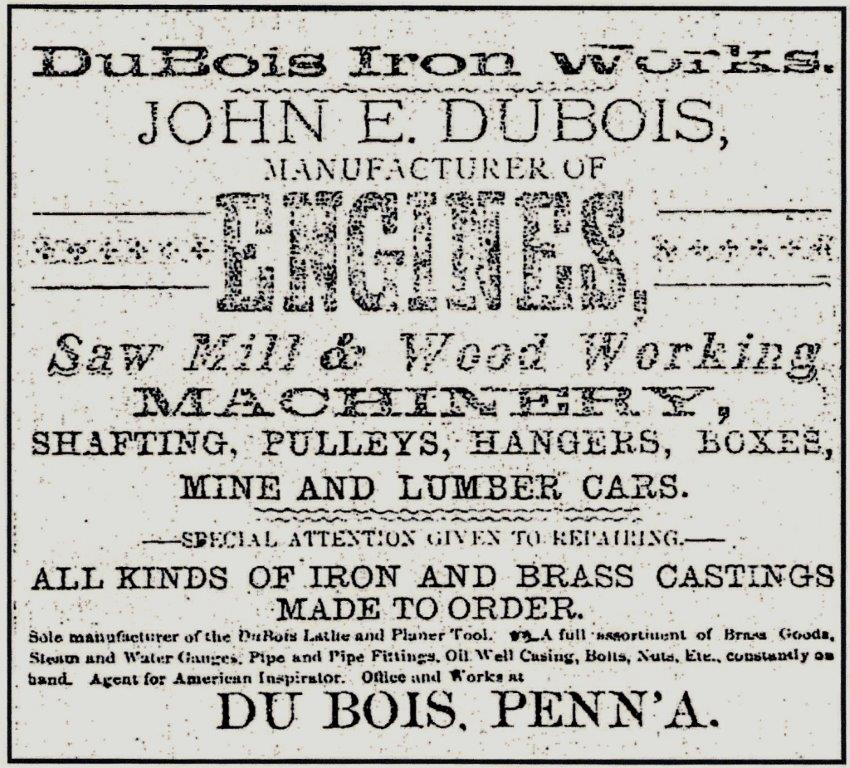

The Iron Works prospered as seen in this

1907 advertisement, Photo 2, showing a beautiful tandem,

double-acting engine. From my collection of documents, I discovered

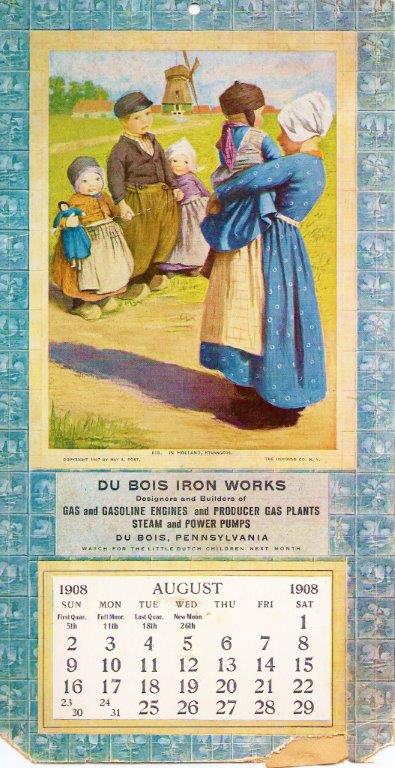

this interesting 1908 calendar, seen as Photo 3. I have

no idea of the significance of the pleasant picture on it.

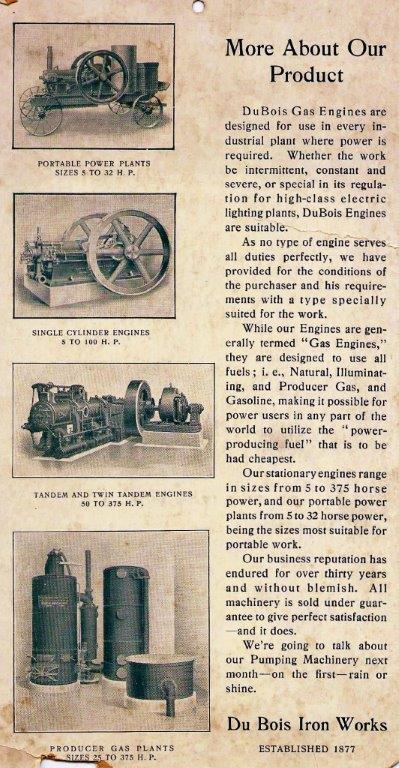

Surprisingly, its reverse carries this illustration of the DuBois Iron

Works products. Note Photo 4. An article in a 1914 issue

of Steele and Iron announced that the Iron Works will build a

new type of engine designed by Samuel Steele and will establish an

extension in conjunction with the Union Machine Company of Bartlesville,

Oklahoma. The engines will be built in DuBois, and some will be

marketed by

Skipping ahead a few decades, we note that John E. DuBois, Jr. in 1940 is listed as the vice president of a gas meter factory. In 1947, the DuBois Iron Works became the Ptttsburgh Division of Rockwell Manufacturing Company. Their product was gas meters, as it still is today. Photo 5, recently taken by the author, shows the majestic buildings of the DuBois Iron Works in all their glory, now manufacturing Sensus gas meters. The structure is 119 years old!

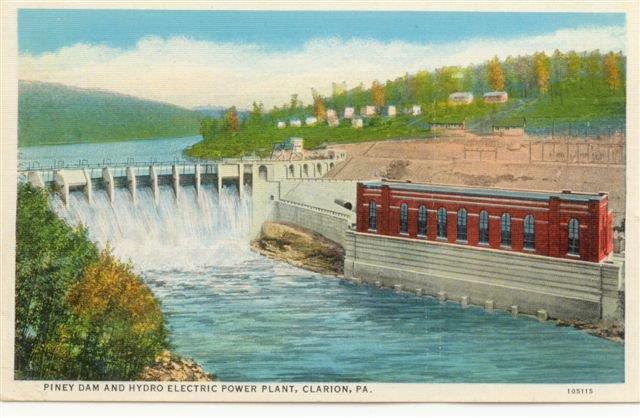

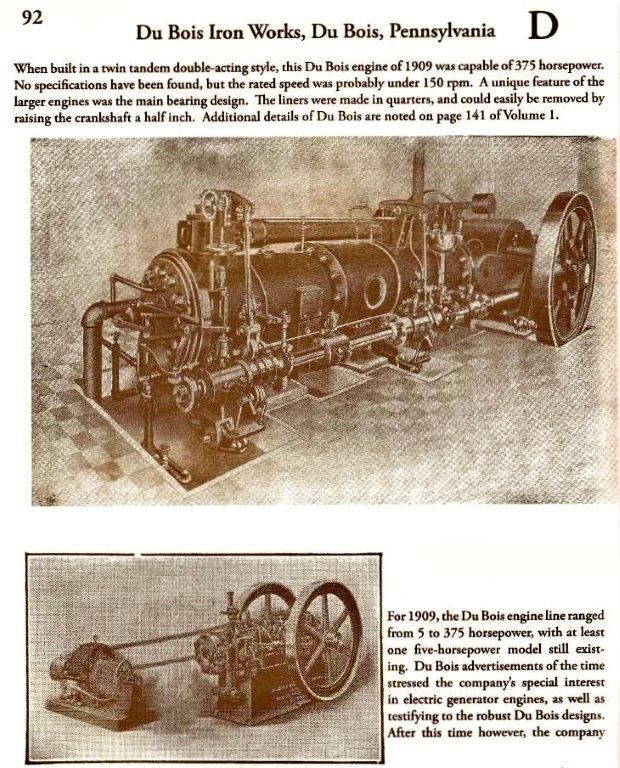

An interesting article was found in a

1909 issue of Power Magazine. Clarion,

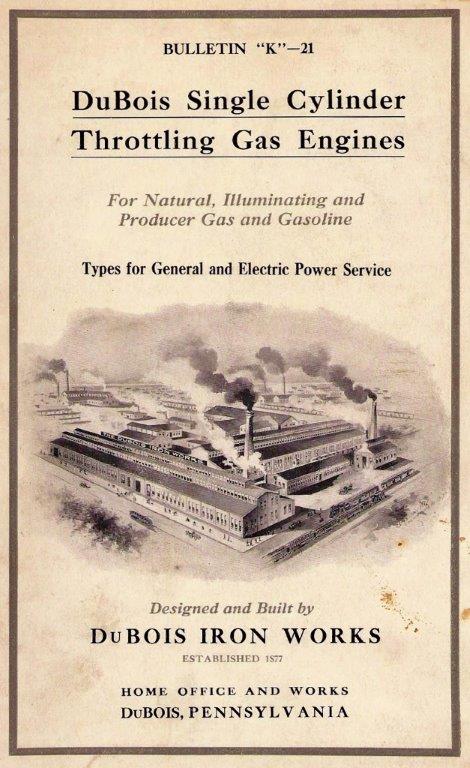

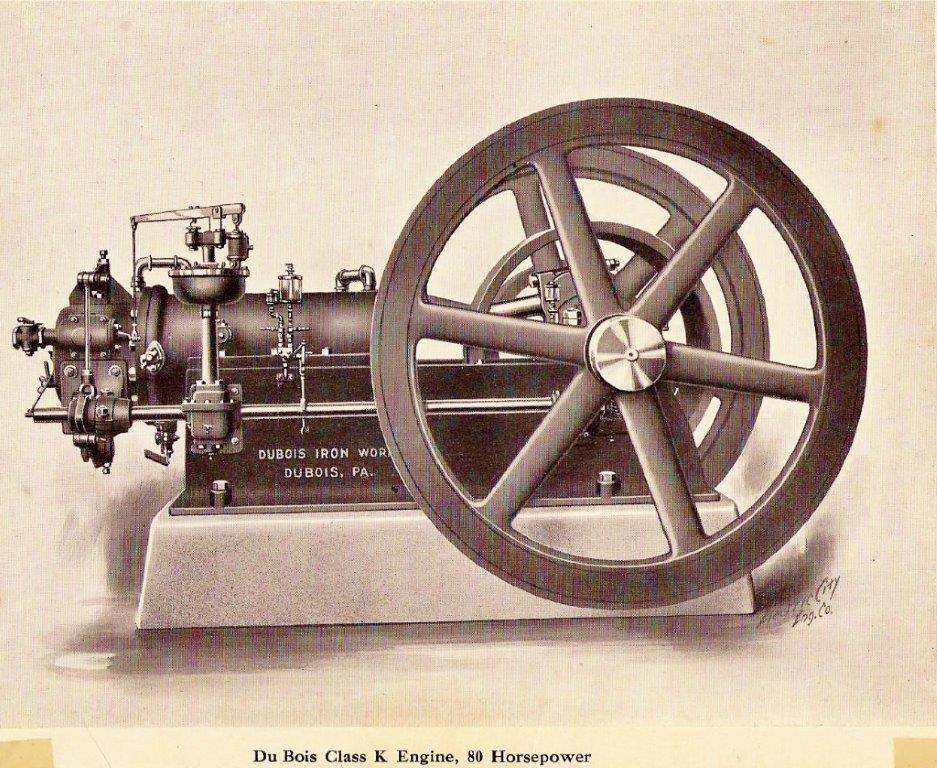

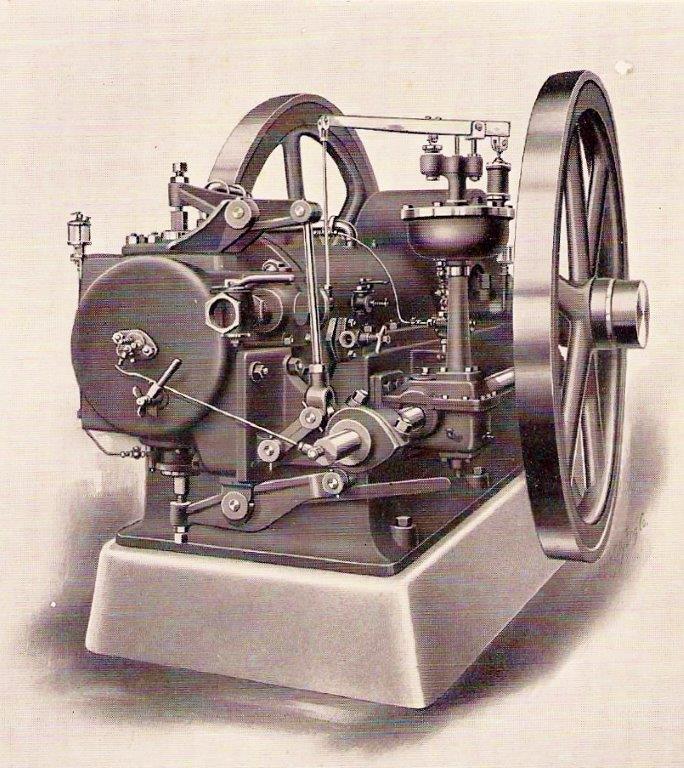

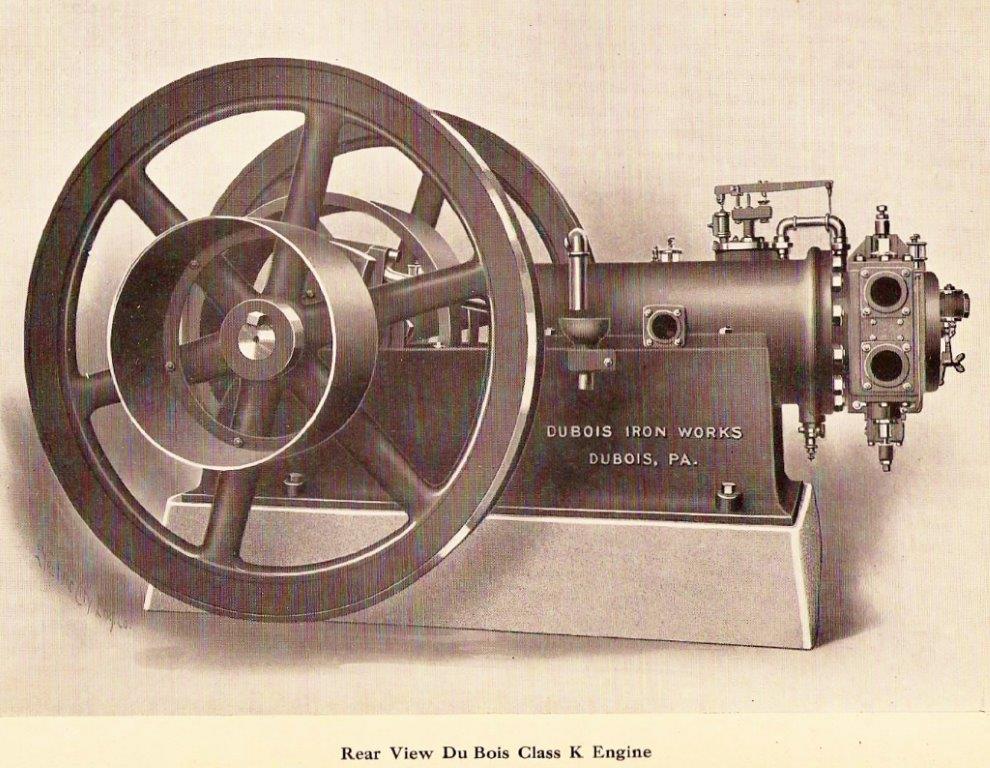

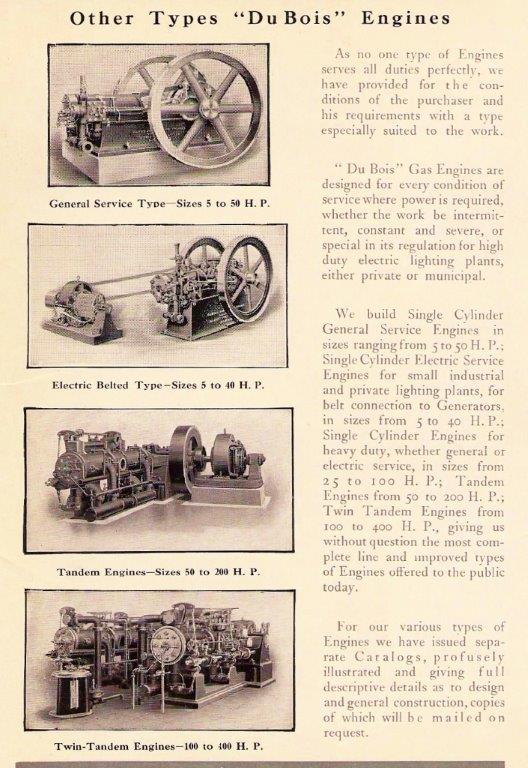

In my literature collection, I am fortunate to have a small DuBois catalog from about 1908. Its cover is illustrated in Photo 7. This bulletin features their special duty throttling engines - the type K. Built into large sizes, they were designed for continuous operation. Photos 8, 9, and 10 show a magnificent DuBois type K engine of 80 hp. Note the excellent finish work and attention to details. They featured a ported exhaust and a vertical governor head. Wonder if one of these still exists? The final page of the catalog is depicted in Photo 11. From this, we see that the museum's engine is noted as the "General Service Type," and was built in sizes from 5 horsepower to 50 horsepower. Amazingly, a twin tandem version, built from 100 horsepower to 400 horsepower, was offered!

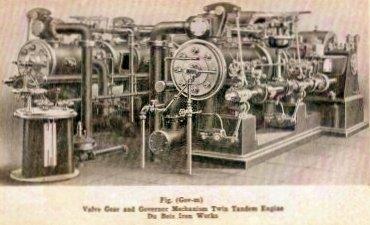

Photo 12, taken from a 1907 advertisement, shows this unusual tandem engine built for electrical generating service. Note the very odd - but attractive - frame design, featuring a pedestal under the cylinder. The single flywheel appears to be very massive. The design would facilitate a direct-connected generator. A huge tandem DuBois, available in several power ranges, is seen in Photo 13. It has two large flywheels, and a long side shaft powering the vertical governor and the valves. The twin tandem engine, built to 400 horsepower, is illustrated in Photo 14. It uses a center-mounted flywheel that might have been used to drive the power belt. The DuBois Iron Works production of gas engines apparently utilized so many designs and power ranges; shown are the ones that I found. Two designers were mentioned, Samuel Steele and Peter Eyermann, but no patents have been found. My catalog just states that the engines were designed and built by the DuBois Iron Works.

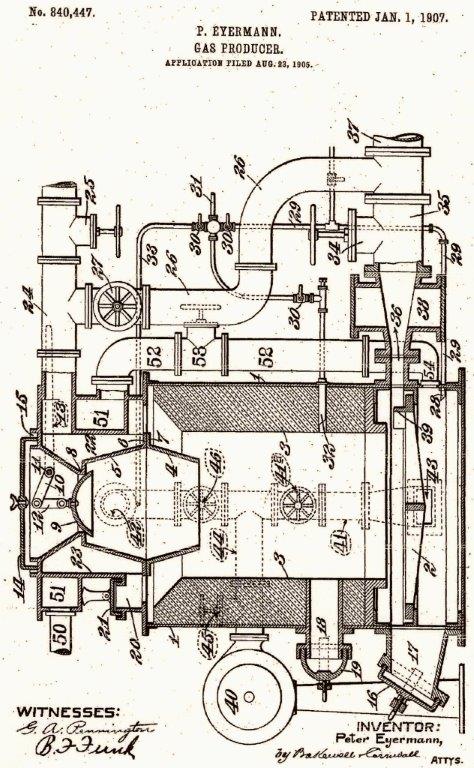

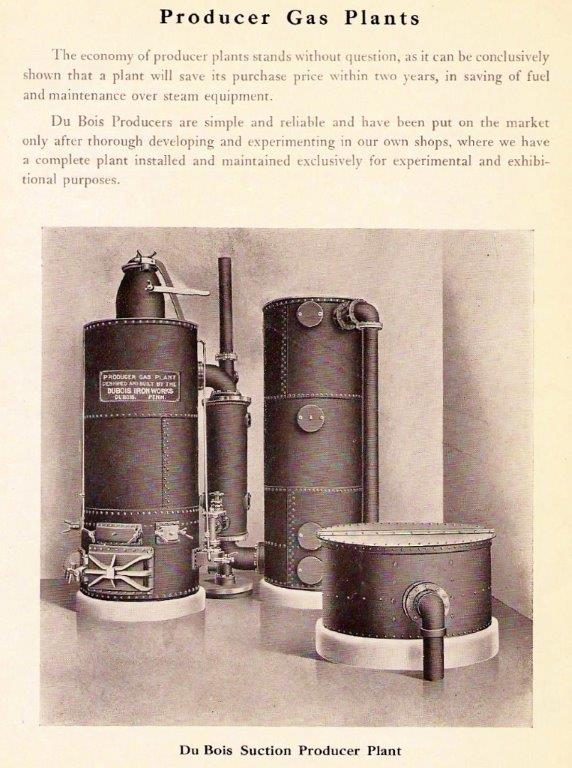

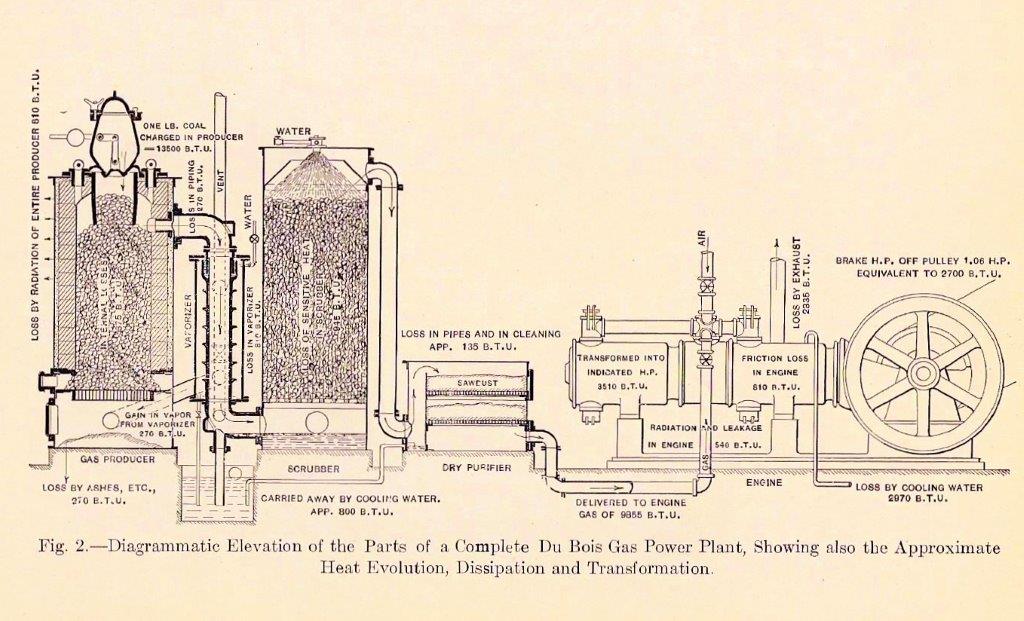

The Iron Works also built a line of gas

producers. These complicated devices heated coal in a retort-like

device with limited air and collected the gas given off for use in

their engines. The product was mainly hydrogen and carbon monoxide.

Both gases are flammable but of low BTU value. As DuBois was located in the vast

bituminous coal fields of w

My 1908 DuBois Iron Works catalog illustrates their gas producer. Photo 16 shows a photograph of the complete producer and the arrangement of parts. This is followed by Photo 17, which is an illustration of the complete arrangement, including heat losses. None of these producers have survived.

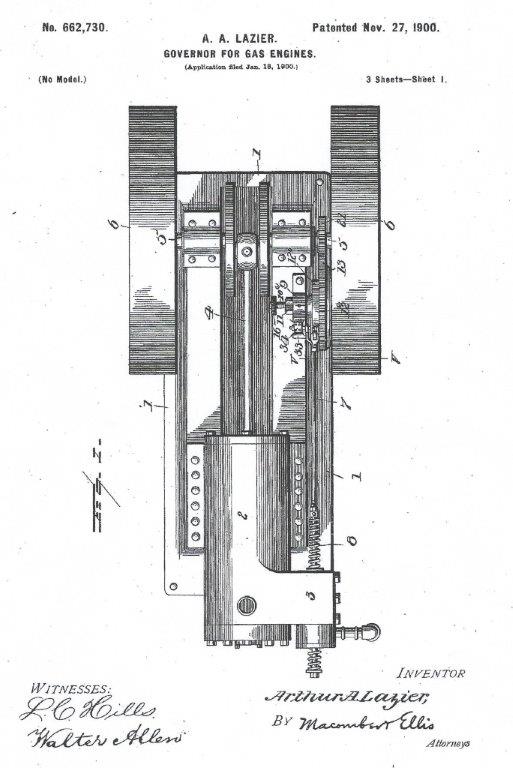

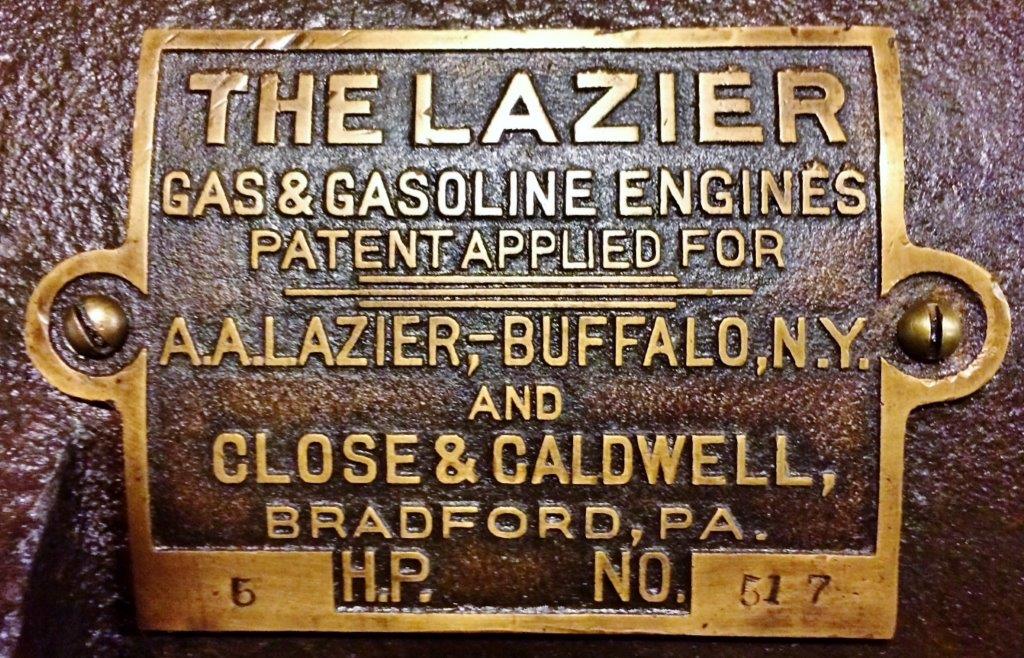

There is a long and very confusing

relationship between the Lazier Gas Engine Company of

It has been known that Arthur A. Lazier

was mainly a designer, not a manufacturer. His engine patent is

shown in Photo 18. It is number

662,730 and granted on

Surprisingly, an article in a 1905 issue

of The Gas Engine notes that an arrangement between the Lazier

Engine Company and the DuBois Iron Works has been completed for DuBois

to again manufacture the Lazier engine. Arthur Lazier has assumed

control, and the main offices will be in

In a two-year turnaround, the

Electrical World of 1907 announces that the DuBois Iron Works have

taken over the entire business of the Lazier Engine Company. Mr. Lazier

sold his entire business, including patents and designs, to DuBois, and

has retired from the engine world. All new engines are to have certain

improvements and be marketed under the DuBois name. The line of engines

will be from 5 horsepower to 300 horsepower, with the improvements

having been designed by Peter Eyermann. The officers of the company

were John E. DuBois, President; W. C. Pentz, Vice President; E. A.

Badger, Secretary and Treasurer; and I. N. Hamilton, General Manager.

Mr. C. E. Stuart, responsible for sales and advertising. Now, the head office and

management was located in DuBois, with a branch in

Interestingly, Arthur Lazier did return to the engine world and didn't waste any time! In 1907, Engineering World announces that he sold his interest in the Lazier Gas Engine Manufacturing Company and formed the Lazier Gas Engine Company. He will now manufacture, or perhaps market, large twin cylinder vertical engines An actual installation is shown in Photo 21. Little else is known about his final venture.

And so the DuBois Story and the Lazier connection ends. Many mysteries yet remain to be discovered!

I wish to thank and acknowledge the following sources from whom I've obtained information. My article was made possible from the information gleaned from them.

Google Books

Newspapers.com

American Gasoline Engines Since 1872, by C. H. Wendel

Nick

Rowland

Ancestry.com

DuBois Historical Society

Personal

Documents and Photos

Next month, I will cross the

Photo 1: Ad from the New Bethlehem Vindicator

Photo 2: 1907 ad for the DuBois Iron Works

Photo 3: 1908 calendar from DuBois Iron Works

Photo 4: Reverse of 1908 calendar showing DuBois products

Photo 5: Former DuBois Iron Works buildings today

Photo 6: Piney Dam in Clarion, Pennsylvania

Photo 7: Cover of 1908 DuBois engine catalog

Photo 8: DuBois 80 hp engine - near side

Photo 9: DuBois 80 hp engine - back

Photo 10: DuBois 80 hp engine - off side

Photo 11: Final page of 1908 DuBois engine catalog

Photo 12: DuBois tandem engine

Photo 13: Tandem DuBois engine

Photo 14: Twin tandem DuBois engine

Photo 15: Eyermann gas producer patent 840,447

Photo 16: Gas producer from 1908 catalog

Photo 17: Illustration of gas producer arrangement

Photo 18: Lazier engine governor patent 662,730

Photo 19: The museum's Lazier engine

Photo 20: Lazier nameplate

Photo 21: Lazier twin-cylinder vertical engines