March 2015

The Mighty 175

By Paul Harvey

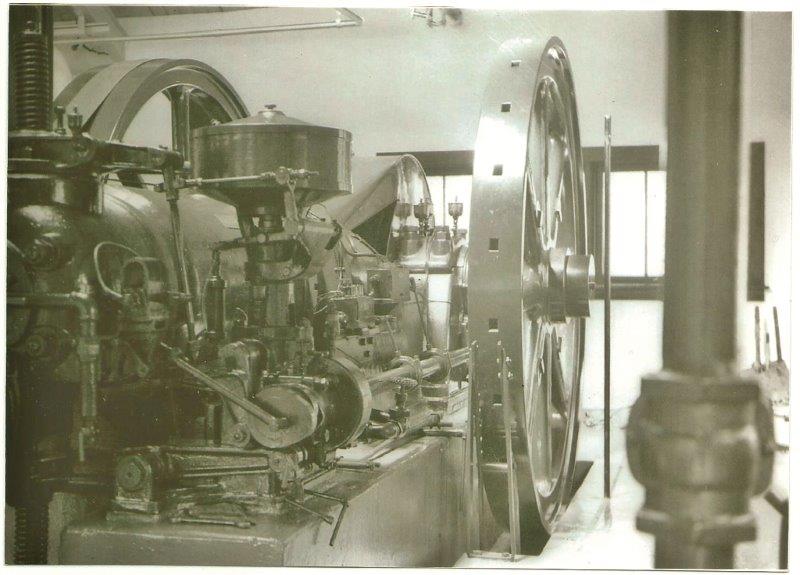

Of all the wonderful engines displayed at the museum, my

favorite will always be the 175 horsepower Otto and the Deane water

pump. This equipment was originally located at the Brookville,

John quickly investigated with a call to the Water Board and found that

the engine and pump, on standby since 1945, was to be replaced with an

electrically powered pump. Successful in obtaining the retired unit, he

spent most all of 1969 dismantling the 25 ton engine and the 20 ton pump

single-handedly. He hauled all the parts to his location in

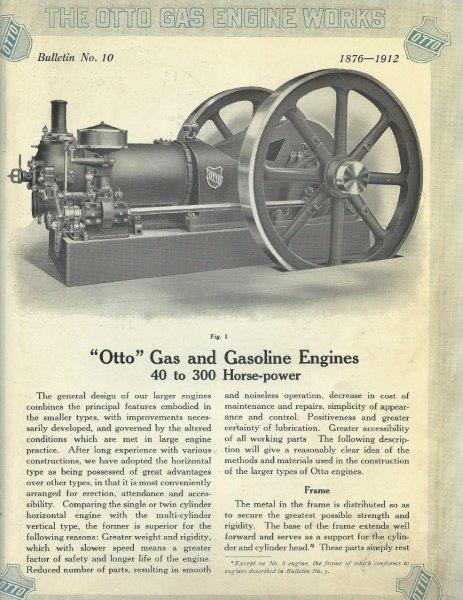

Looking back into history a bit, Brookville built a beautiful new water works in 1911 as shown in Photo 1. It was located on North Fork Creek which provided unlimited pure water from a watershed of many thousand acres of pristine forest. It replaced an older steam plant that could no longer provide the town's needs. Note the room on the right of the building; it housed an 80 horsepower Otto. Fifteen years later, it would be the home of the Otto 175.

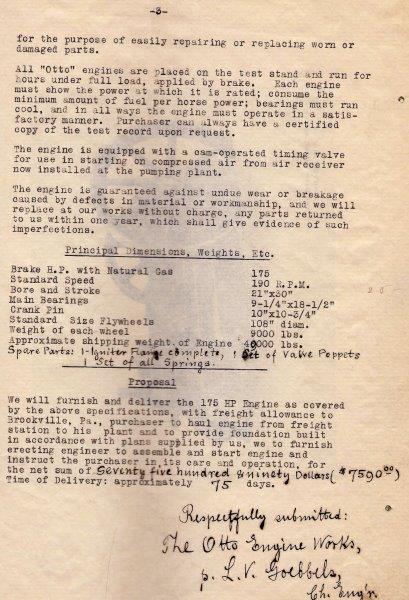

In 1925, the Water Board recognized the need for a larger pumping unit.

Borough engineer, Fred Sayer, applied for engine bids of a 175

horsepower unit. He considered a

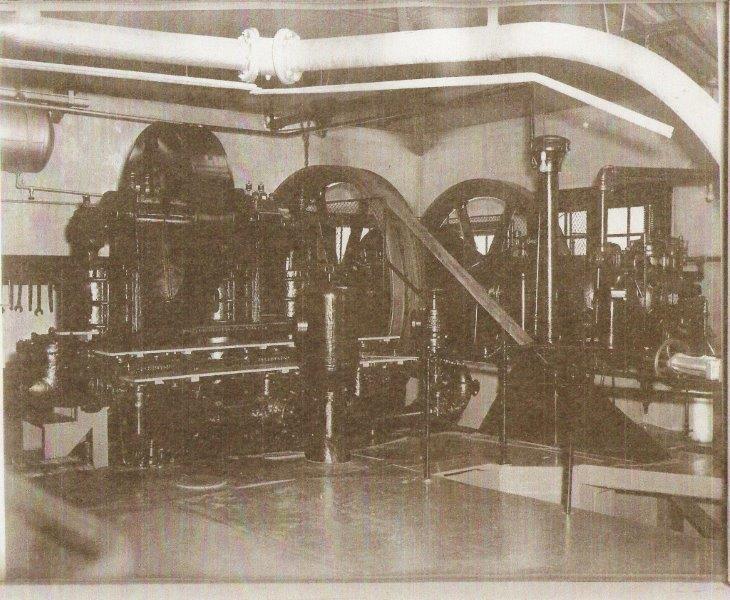

An undated picture from the Water Works file, shown as Photo 4, is the Otto and its pump during its working years. It was meticulously maintained and operated by plant engineer, Reuben Ferringer. Its location was in the side room of the water works as mentioned above. Note the flat belt over the flywheel and extending into the basement. This powered a centrifugal pump that brought the water from the dam into the sedimentation basins. There the water was filtered, with the Deane triplex pump finally pushing the water uphill some 300 feet to the town's reservoir. Gravity delivered the water to all the users. The engine ran 24 hours a day from Monday morning till Saturday afternoon; then the reservoir supplied Sunday's needs.

Photo 5, taken by John Wilcox in 1968, is one of the last

before the engine was dismantled. Although on stand-by for 23 years,

Rube kept the Otto and pump in pristine condition, and it could be

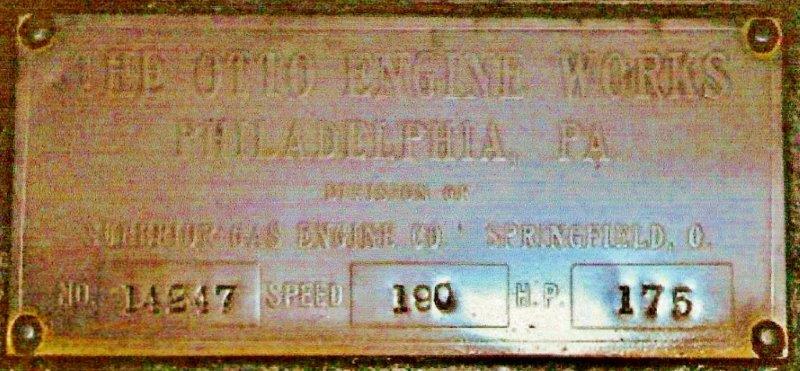

started on a moment's notice. The Otto nameplate is detailed in

Photo 6, and shows that the Otto Engine Works was then a

division of the Superior Gas Engine Company of

Jumping ahead to 2005, I had purchased the Otto and pump from John

Wilcox, and he furnished me with all the records he had obtained from

the Brookville Water Works. Fortunately, these included the original

foundation blue prints! After choosing a location in the

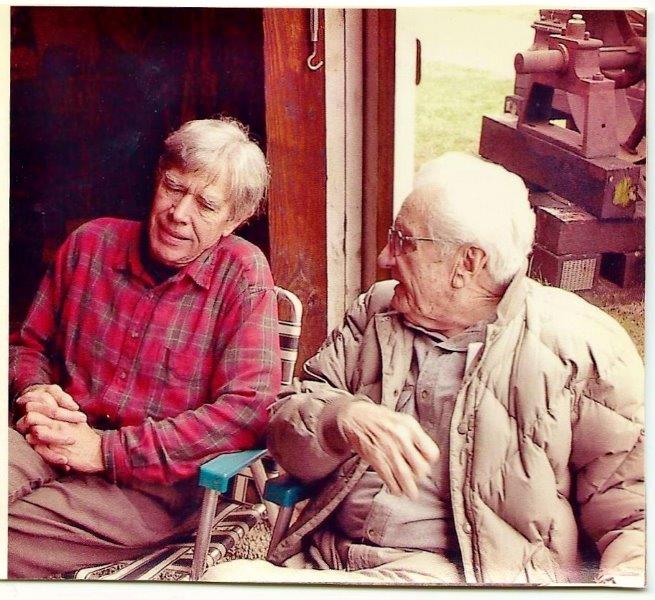

Enthused by the progress, the museum crew and I planned a trip to John's

home in

A candid picture from the Fall Show,

The entire summer of 2006 was spent by cleaning, fitting and assembling! The huge engine cylinder bore had to be cleaned of its preservative grease and lightly oiled, to accept the piston. Similarly, the piston and rod had to be meticulously cleaned before re-assembly. Likewise, the huge crankshaft needed cleaned and fitted into its bearings. Many small parts were cleaned and assembled. Valves were ground and assembled. Finally, the entire main frame had to be precisely leveled and grouted onto the foundation block. A long and tedious job, but now all the parts and pieces we had in Coolspring were assembled; we were ready for the flywheels. Unfortunately they would have to wait until the next year as winter was approaching.

After the 2007 June Show was over, the crew chose the weekend of July 4

for retrieving the flywheels. We took the same two trucks as before to

John's location in southeastern

All the details were finished, including an underground

outside exhaust and gravel floor, before the 2007 Fall Show. The engine

now ran smoothly and dependably. We held the Otto dedication on

The next two years were consumed by moving all the pump

parts to Coolspring and preparing them for assembly. Unfortunately, the

pump had been stored outside, unlike the engine which had been inside a

building all those years and well maintained. The pump's critical parts

had been greased, but otherwise it was covered with rust. Rob Northey

joined the crew and undertook the massive job of wire-brushing all the

parts and preparing them for erection. I have no idea how many wire

wheels he used transferring all the rust from the parts to himself! He

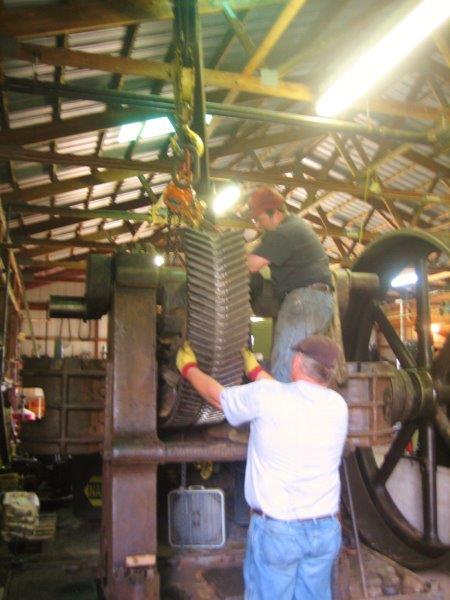

was determined, and gradually it took shape. Photo 15

shows Rob and

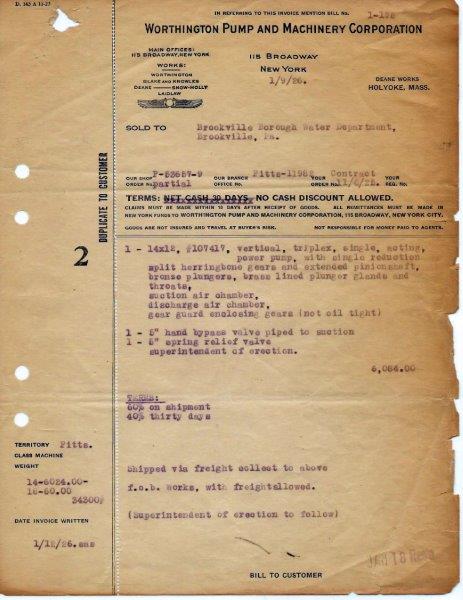

The Brookville Water Works awarded the contract for the

Deane pump to

Rob is now the chief engineer for the Otto and Deane, and proudly demonstrates it for all our events. Photo 18 shows Rob starting the Otto in June 2014, as it was being filmed by WJAC-TV for a television production.

Come to

Photo 1: Brookville Water Works in 1911

Photo 2: The contract for the engine dated

Photo 3: Page from an Otto catalog circa 1925

Photo 4: The Otto and pump in the Water Works

Photo 5: The Otto in 1968

Photo 6: Otto nameplate

Photo 7: Foundation for the Otto

Photo 8: Main frame on the tilt-bed truck

Photo 9: Piston and crankshaft about to leave Ohio

Photo 10: Main frame on foundation in September 2005

Photo 11: John Wilcox and Rube Ferringer

Photo 12: Clair Exley, Mark Himes, and Ken Uplinger loading the second flywheel

Photo 13: Clair Exley on the throttle with Mike Murphy and Doug Fye observing

Photo 14: Rube starting the engine at the dedication

Photo 15: Installing the top half of the herringbone gear

Photo 16: Contract for the Deane pump

Photo 17: Deane pump nameplate

Photo 18: Rob Northey starting the Otto in June 2014