|

September 2014

Pattin Brothers: Ohio's Oil Field

Engine

By

Paul Harvey

Lt. Col. Thomas Jefferson Pattin fought gallantly in the

Civil War as a leader of the Ohio First Cavalry. After the war, he

returned home to his wife and family who waited in

Marietta, Ohio, and soon

became listed as a master mechanic. A bustling river town,

Marietta was growing, being transformed from an

agricultural hamlet into an industrial city. Oil had already been found

at Titusville, Pennsylvania,

and the boom was marching south. Soon Marietta

would be a hub of the new trade - oil field equipment! And so our story

starts...

Lt. Col. Pattin had four children, three sons born before the war and one

daughter after. Two of the sons, Winfield and Douglas, shared his

mechanical aptitude and joined with J. G. Hall in 1888 to form Pattin,

Hall, and Pattin. They built a machine shop in the west side of the

city. In 1895, The Pattins purchased Mr. Hall's interests and formed

Pattin Bros. & Co., building a new plant on

Second Street. Business was good so they

continued the original works as well, employing about 50 men at this

time. The new firm grew as shown by the 1907 letterhead in Photo

1.

Winfield Scott Pattin was born in 1851 and attended

Marietta College

in the early 1870s. He was listed as a machinist in 1873, then moved

to Scott County, Missouri, in 1875 where he married Cecelia Cullum.

They moved back to Marietta

in 1880. Ironically, he died of pneumonia on a business trip to the

West Virginia oil fields on March 27, 1913. His younger brother, Douglas P.

Pattin, was born in 1859 and spent his life in

Marietta. He was also a machinist and deeply

involved with the new firm. On the morning of October 20, 1901, Douglas and two other persons

visited the big plant on Second Street.

Having done what was needed, he left his companions to investigate the

strong odor of natural gas. Moments later, as his friends were walking

away, a huge explosion occurred and the plant was immediately engulfed

in flames. His remains were found that evening. According to the

Marietta Register, the firm of Pattin Brothers rebuilt and grew

stronger.

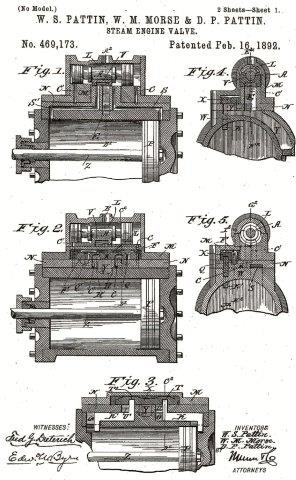

Both Pattin Brothers shared only one patent together, which is shown as

Photo 2. Granted on February 16, 1892, number

469,173, it

concerns the operating valve for a steam engine.

Marietta was now in the midst of the oil boom and

needed steam engines to both drill the wells and then pump them. The

steam engine became one of their major products. Pattin Brothers also

built all kinds of oil field tooling and equipment.

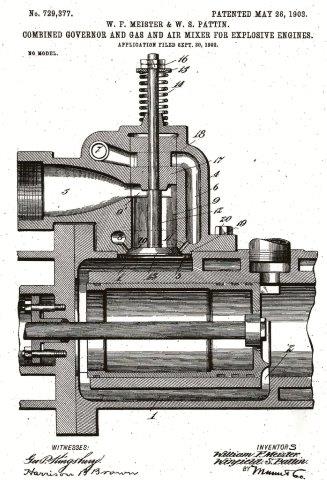

The gas engine patent did not occur until after Douglas's

death. It is shared by W. S. Pattin and W. F. Meister. A combined

governor, included in the gas and air mixer, was patented on

May 26, 1903. Number

729,377 is shown as Photo 3.

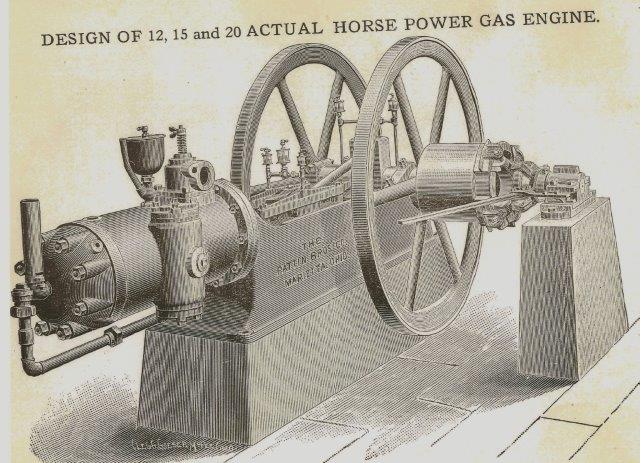

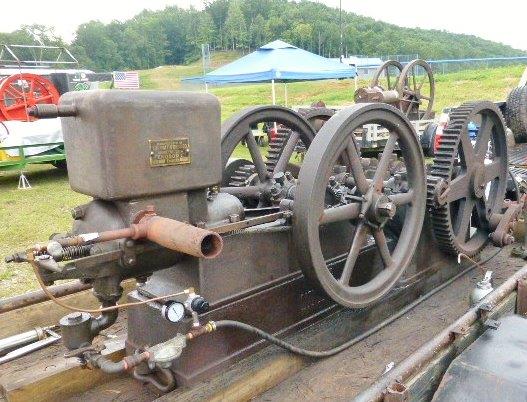

There has never been a similar device that worked so well. A drawing

of the original engine is seen in Photo 4, and an existing

example in a Parkersburg,

West Virginia, collection is seen in Photo

5. This indicates that the original design was two-cycle and

shares many features that were seen in later engines. Note the cylinder

oiler with the air vent and the engine's long, narrow lines. The four-cycle engines bearing the EKONOMY name came later.

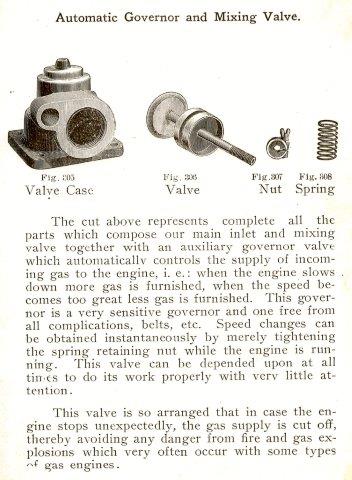

Photo 6, taken from an undated photo, briefly explains

the "Automatic Governor." The intake valve, which admits the fuel gas

through holes in its tapered seat, also carries a cylinder valve with

circular openings for both the air and gas. As the engine speed

increases so does the stroke of the intake valve. This lowers the

cylinder valve which reduces the amount of air and gas available. And

so the engine slows and returns to regular operation. Close examination

of the patent drawing, Photo 3, will show the

position of the valves. Engine speed can be controlled by tightening or

loosening the nut on the intake valve. Very ingenious!!

William Meister began working for Pattin Brothers on

January 12, 1891, as an apprentice. Two years later, he

moved into the foreman position and from that time had an ever

increasingly responsible role in all the company's developments. He

held the patents for the Pattin Brothers combination engine and power,

and the MEISTER feather valves used on later compressors, as well as

several others. After Winfield's death, he became president and general

manager. In the mid-1940s, Pattin Brothers was purchased by Acme

Fishing Tool Co. of Parkersburg, West Virginia.

Acme president, L. M. Ludlow, said that all the operations of Pattin

Brothers would remain the same, including Mr. Meister as general

manager. And so the name lived on for many more years.

Pattin Brothers products were diverse but all were oriented to the oil

fields and its needs. Most of the equipment was used in the local area,

although they had a major distributor in Bradford,

Pennsylvania. Photo 7 shows a

belt driven Pattin Brothers pumping power. This is located in the yard

of the

Oil and Gas

Museum located in

Parkersburg, West Virginia.

Containing a huge array of local oil field artifacts and equipment, this

museum is certainly a delight to visit. While attending the "By the

Lake" show near Harrisville, West Virginia, I spotted this 4 1/2 hp

Pattin-United combined engine and pumping power. See Photo 8.

Note the horizontal hot tube and chimney which is the original

location. I am unsure of the connection of Pattin and United but these

engines were used on several of Pattin Brothers products. The name

plate on this engine states "manufactured by Pattin Brothers." Oddly,

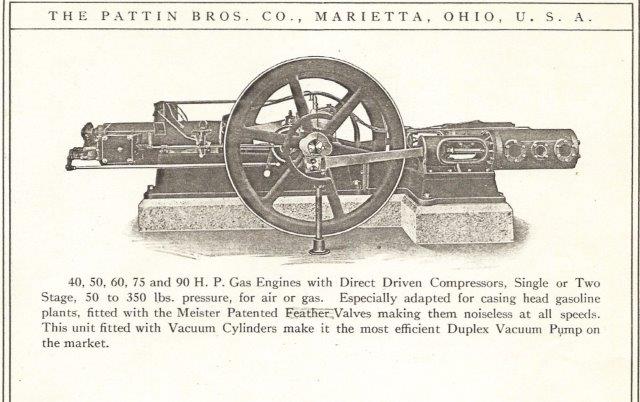

Pattin Brothers did build a five horsepower engine. Photo 9

depicts a four-cycle engine with opposed compressor cylinders.

Taken from a 1920 catalog, these units were built in 40, 50, 60 and 90

hp sizes. A 40 hp example will be arriving in Coolspring this autumn!

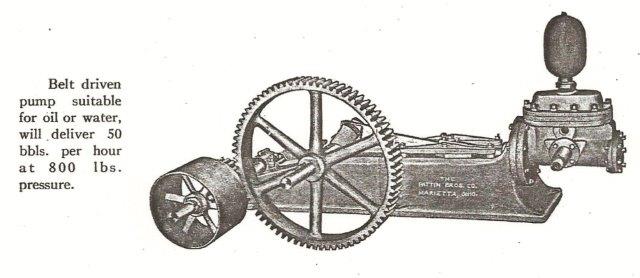

The 1920 catalog also shows a vast array of belt driven pumps as seen

in Photo 10.

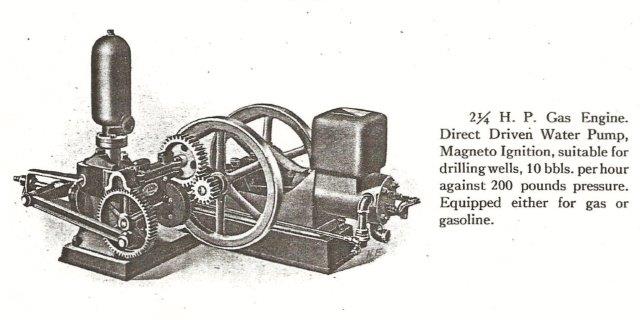

Photo 11, taken from the same 1920 catalog, shows a small

engine and pump combination. Again, it is unclear if these small units

were built by Pattin Brothers or assembled from items made by others.

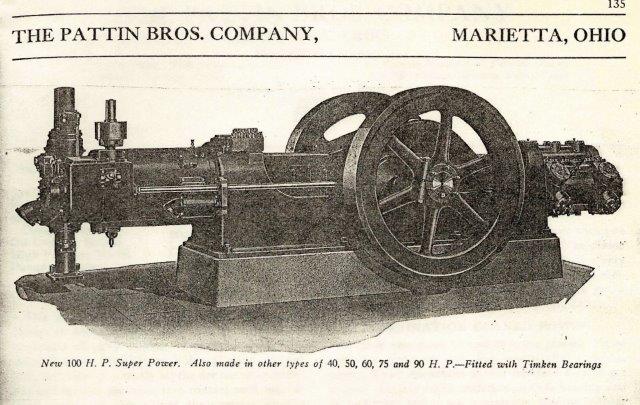

The largest engine built by Pattin Brothers was the 100 hp "Super Power"

engine compressor unit. A 1925 catalog shows this unit; Photo

12. These huge units were four-cycle with over and under intake

and exhaust valves. Being ported and having a side shaft, they employed

a rotary valve to close the exhaust port in the intake stroke. This

feature is

unique to the Super Power. Opposed to the engine cylinder are twin, two

stage compressor cylinders, one mounted above the crankshaft and the

other below. History relates that only three were built and one still

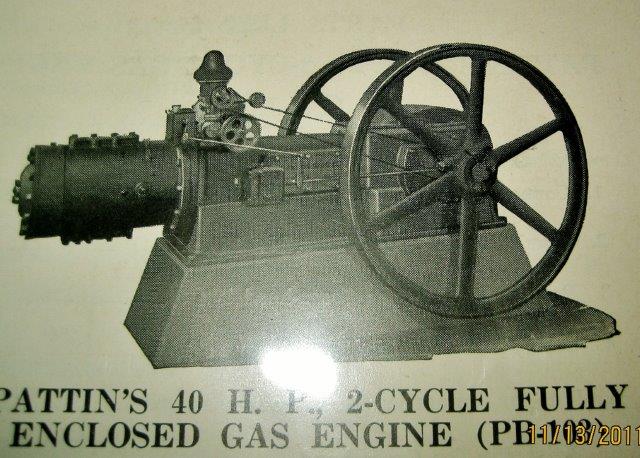

survives at its original location. Photo 13 shows an old

photo of the (apparently) late design, 40 hp fully enclosed model. This

photo was found in the Oil and Gas

Museum archives. Note that they have

reverted to the two-cycle design, as the original was.

Coolspring

Power Museum

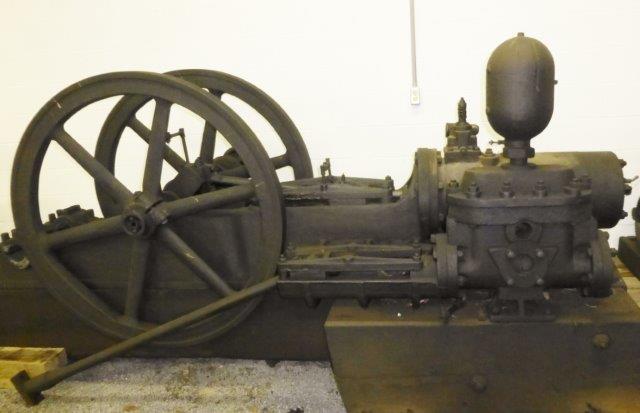

is proud to display seven Pattin Brothers engines. Photo 14

shows a 25 hp four-cycle model. Having pumped an oil lease in southeastern Ohio, this model

is hit and miss governed by a nicely done vertical governor, which

disables the gas valve. It has both hot tube and high bar KW magneto

ignition and a ported cylinder. Note the location of the flywheel

counterweights! A 20 hp combination engine and power is shown in

Photo 15. It is four-cycle, hit and miss, and sports the

EKONOMY name plate. Originally located in Dallas Hollow near

Bradford, Pennsylvania, it

came to Coolspring in 1969. Photo 16 shows a 15 hp four-cycle Pattin Brothers engine that has a pendulum governor. According to

a vintage catalog, the smaller models, 12, 15 and 20 hp, had the

pendulum governor and the large ones, 25 to 90 hp, had the vertical

governor. As with the 25 hp model, this one is hit and miss with the

governor operating the fuel valve. It pumped an oil lease near

Wingett Run, Ohio, and has

been in Coolspring since 1970. A 15 hp, two-cycle model is shown in

Photo 17. It retains the lines of the original model but

does not have the automatic intake valve governor. It was found in

northeastern Pennsylvania.

Photo 18 is a 12 hp two-cycle engine with attached pump.

Found near Marienville,

Pennsylvania, it does not have the back gear

with the pump crank mounted on it at this time. It was ideal to pump a

small oil lease and equipped to then transfer the oil to the nearest

National Transit pipeline station. Unique idea! A small brother to our

20 hp combination engine and pumping power is this 8 hp unit as shown in

Photo 19. It also came from Wingett

Run, Ohio, many years

ago. The local oil producer greatly preferred these small Pattin

Brothers units over the Kootz & Strohman and Spence units for

dependability. It interesting to note that an enthusiast has imported

one of these 8 hp combination units to

New Zealand! Photo 20

shows the 8 hp engine, which is similar to the 8 hp combination, being

operated at one of our shows. Found near Marietta

in 1969, it was belted to a small Pattin Brothers power to pump one

well. A 5 hp model of this engine was also produced and several

examples still survive.

Please visit Coolspring

Power Museum

for our Fall Show & Swap Meet held on October 16, 17, & 18, 2014.

Several of the Pattin Brothers engines will be in operation. This

will be our last event for 2014. Special tours can be arranged by

advanced appointment during the winter. Next year will be our 30th

anniversary show, The Flame Ignition Expo! It promises to be the

largest assembly of flame ignition and slide valve engines ever.

Keep in touch by watching our web site

www.coolspringpowermuseum.org or calling 814-849-6883. See you

then!

|