|

May 2014

Windy City

By

Paul Harvey

Nestled deep in the Allegheny

National Forest was a little community named

Windy City.

Don't bother to find it now for it no longer exists. Southwest of Kane,

Pennsylvania, and through the town of James City, one finds a lonely

forest service road that leads on a few miles to an open, grassy site

with a space big enough to turn around, as shown in Photo 1.

My last visit to the site was in 2009 and the wind seemed to whine

in the pines, recalling much happier days. Alone with the ghosts of days

gone by, I could again see the few houses and buildings and hear the

loud exhaust of the Blaisdell engines from the air plant echoing across

the valley floor. This is Windy

City and this is its story.

I first stumbled upon Windy

City in the late 1960s while driving some

desolate back roads in search of old engines. Suddenly I found myself

in a forest of ancient steam engines, each rigged to pump an oil well.

At one stop I could definitely hear the bark of large gas engines,

so I

headed in that direction. Driving on for about two miles, I came upon a

green building, standing open, with two large Blaisdell combination gas

engine-air compressor units in full operation. I had never seen such a

sight! After wandering around a bit, I was greeted by Harold "Jim"

McCauley who was station operator, well pumper, and maintenance crew all

rolled into one. Jim was the sole resident of the town and the total

work force that kept the lease pumping for Kendall Refining of Bradford,

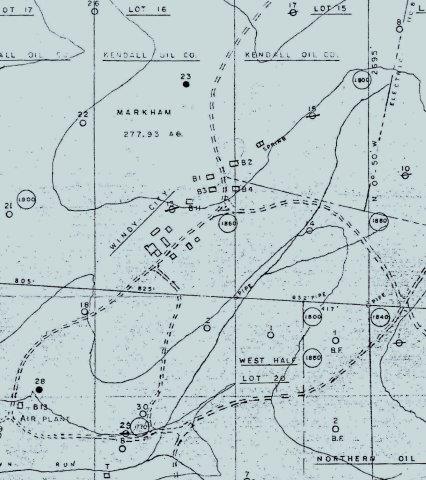

Pennsylvania. Photo 2 is a 1972 topographical map that

shows the buildings of the community as well as the air plant location.

Over the years Jim and I became very good friends, and he explained much

of the history and technology to me. He taught me how to operate the

Blaisdells and how to know when an oil well was "pumped off." He

thought that Windy

City was probably born in the 1880s when the

oil wells were drilled with the steam engines that still pumped them.

The community was always small and focused on the oil and timber

industries. The lease, consisting of 44 oil wells, was known as "The

Griffith" and was operated by Kendall. As the

wells gradually declined and the boilers deteriorated, a new method of

pumping was needed. In 1916, an air plant containing the two Blaisdell

engine-air compressors was erected to provide compressed air to operate

the steam engines, replacing the aged boilers. This proved very

successful and many other plants were erected in the neighboring areas.

Only four wells were still in operation on the plant's final day of

operation, July 12, 1989.

One lazy afternoon, I asked Jim why he had chosen to stay at

Windy City.

He just replied, "It's a good life." He continued to explain that he

loved to hunt, so during the autumn and winter he could take his gun

with him, get the plant running and some wells pumping, then hunt

for a

couple of hours to get some fresh meat for supper. During his later

years there, he bought "Big Red," a four wheeler, to save walking to all

the well sites. Loving to keep the well sites and station area well

mowed, he always carried his faithful scythe on Big Red, stopping to

trim a bit here and there. His scythe, which he pronounced as "sigh,"

still hangs in our Windy

City air plant exactly where he kept it.

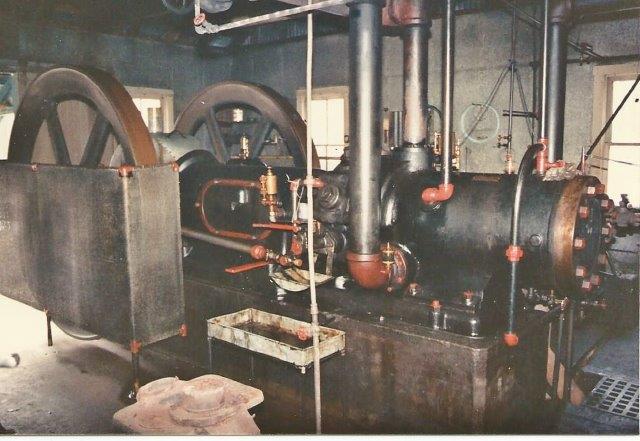

Photo 3 shows the museum's Blaisdell, still on location

and operating, in the early 1980s. The Blaisdell engines were

manufactured in Bradford,

Pennsylvania, and the firm still exists today

making Zippo lighters! One engine could pump two oil wells and both

engines together could pump five wells. Perhaps not very efficient but

definitely better than the individual boilers. Sometimes, if Jim was

not in town when I visited, I would just make myself at home (I knew

where he kept the key) and start this engine to relax a couple of hours

in his rocking chair, falling asleep to the rhythm of the exhaust and

the motion of the engine. I would then replenish the starting air, wipe

everything clean, drain and shut off the water, and leave without a

trace. At least I thought I left without a trace! Later, Jim

told me that he was aware of my visits!

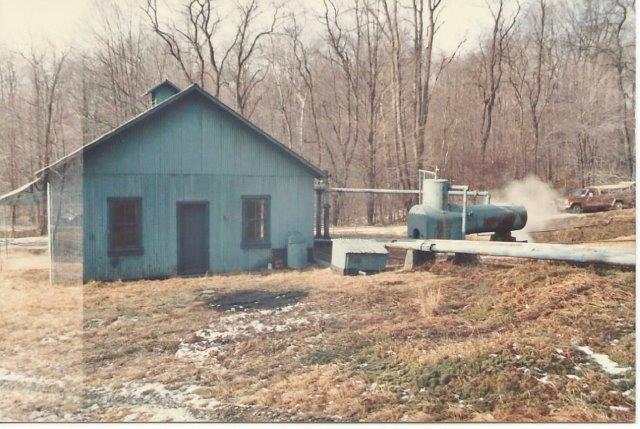

The Windy City

air plant in operation is illustrated in Photo 4. Note

the old boiler to the right which served as the first air receiver and

the long pipes laying near the ground which allowed the air to cool and

the moisture to condense before being distributed to the steam engines on

the wells. The plume of steam behind the boiler was rising from the

water cooled engine exhaust which belched out over a small stream.

The compressed air, maintained at 80 psi, operated the individual steam

engines as shown in Photo 5. The gear reduction was known

as the "cog wheel" and operated the walking beam at 24 strokes per

minute. Crude oil produced from each well gravitated to a large tank in

the valley where it would be transported by truck to the refinery.

When the Windy

City air plant finally closed its doors in

the summer of 1989, Coolspring

Power Museum

acquired the complete building, its contents, and one of the Blaisdell

engines. During its final few years of operation,

Windy City

had been under Pennzoil management. The structure was dismantled and

all the interior pipe work, parts, and equipment were photographed so

that assembly would be an exact duplication of the original. With

everything moved to the museum, the project of installation and

reassembly began. Two changes were made as the project unfolded. First,

we decided to widen the building five feet to accommodate our visitors'

safety by providing more observation space. Second, since we had only one

of the Blaisdells, we decided to add our Flickinger gas engine-air

compressor, removed from a similar air plant in

Bradford, Pennsylvania, to

replace the other Blaisdell. Both changes proved to work well.

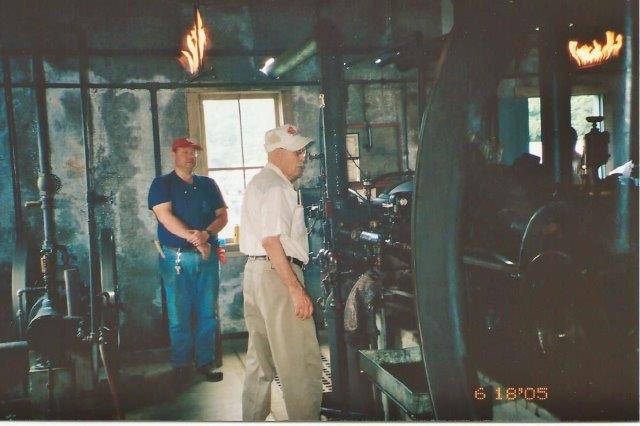

During the Museum's 2005 June show, we had a delightful visit

from Jim, his last to see his beloved air plant as reconstructed at

CPM. The Blaisdell was running and the gas lights were lit as Jay, our

engineer, chatted with Jim. Jay then asked Jim if he could still start

the engine, and proceeded to stop it. Jim just said, "Course I can!" and

proceeded to go through the entire procedure and had it running much

easier than we ever did. See Photo 6. He then proceeded

to instruct us on some fine points of operation to ease the starting

procedure which we have used ever since. He passed away the

following winter at the age of 90 or so.

Photo 7 depicts the front view of our re-erected

Windy City

air plant as seen a few weeks ago. It has been in operation for over

ten years now, and the exhaust report of the Blaisdell can still be

heard over two miles away. Photo 8 shows one

of the original steam engines, a 12 hp Farrar & Trefts, made in

Buffalo, New York.

We installed it next to the Windy City air plant in 2013. It

again operates on compressed air, and we plan to include the walking beam

and well head to the display this year.

Our Blaisdell gas engine-air compressor unit is shown in Photo 9.

These units are massive with seven foot diameter flywheels and

weighing twelve tons. It is rated at 65 horsepower with an operating

speed of 180 rpm. The same cylinder is used for both the engine and the

compressor, having a bore of 16 inches and a stroke of 20 inches. The

head end of the cylinder is the gas engine, which has a side mounted

valve chest containing the power operated intake and exhaust valves.

This is easily seen in the photo. Engine speed is controlled by a small

pendulum governor carried on the intake valve pushrod. In event of

over-speed, the pendulum fails to open a small fuel valve. The rear end

of the cylinder toward the flywheels is the air compressor. Sealing

this on the piston rod is a "stuffing box," or packing gland, so the rod

can end in a sliding cross head. The intake to the compressor is

accomplished by a rotary "corliss" valve that is power operated.

Compressor discharge uses pressure actuated poppet valves. It is a

magnificent machine to see in motion!

As supplied from the factory, Blaisdell provided a diminutive version to

provide starting air for the larger machine. The unit, noted in

Photo 10, was intended only to run when needed to replenish the

starting air tank. Having a five inch bore and six inch stroke, it

operates at 400 rpm. Interestingly, it does not have timing gears but

employs an unusual "wig-wag" cam to impart four-cycle operation. Note,

to the right of the starting engine, the vertical piece of well casing

pipe with a lid and skillet on top. Having a gas burner inside, this is

one of the devices that Jim used to heat the building as well as to cook

his lunch. It is exactly as he left it.

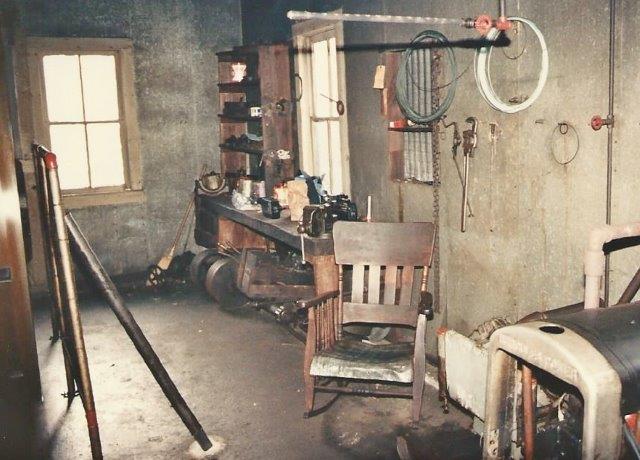

The museum tried to duplicate exactly the lay-out of the air plant as it

appeared in its days of operation. Photo 11 shows the

interior, just beside the big Blaisdell, as it appears today. Jim

loved to sit in his rocking chair while eating fried bologna sandwiches

cooked on the heating stove. The work bench has his vise and all the

spare parts and pipe fittings. One can see the spare piston and rod

stored under the bench. Looking at Photo 12, one will

travel back to the late 1970s and view a remarkably similar scene. Note

the favorite rocking chair, the work bench, the vise, all the parts

including the piston underneath. History has been preserved for all to

appreciate.

Photo 13 shows the 50 horsepower Flickinger gas engine-air

compressor that we installed in our Windy

City display. Like the Blaisdell, it was

also built in Bradford,

Pennsylvania, and served a similar purpose

within the city limits of Bradford. Its home was

on West Washington Street

where it pumped a small group of oil wells with compressed air. The

overall principal is the same as the Blaisdell's, but it features

several interesting design differences. Most noticeable is the side

shaft and vertical governor head. Having some significant problems, it

is finally going back together and will be running in the near future.

Flickinger also supplied small gas engine-air compressor units for

filling the starting air receiver tank. These were the most

attractive, and probably the most serviceable, of the several small

engine-compressor units manufactured in Bradford.

Photo 14 shows the one we have added to our display to

compliment the big Flickinger. These little units were marketed for

many applications where compressed air was needed. Beside the engine is

a vertical air storage tank capable of being filled by either of our

starting engine-compressors and storing enough air to provide several

"starts" of the big Blaisdell. A monkey wrench hanging on the

small pipe leading to the pressure gauge is difficult to see in the

photo.

Jim used it to securely turn off the air tank so the pressure would not

leak away, and we continue to do the same.

For additional photos of both air plants as well as

patent drawings of the engines, please see our website,

coolspringpowermuseum.org. On the home page, click on the "Exhibits"

tab then scroll down to Windy

City. Click on "Tour"

for a detailed trip to the air plant, both in the days gone by as well

as today. You will have a great tour.

After the Windy

City air plant officially ceased production

of crude oil, the museum did a video of a special operation. On

July 12, 1989, Jim hosted a museum and filming crew, starting

the Blaisdell and operating a steam engine. He dictated an

excellent documentary of all his thoughts and actions, and this was

recorded. "Windy

City Air Lease...Its Last Run," a 45 minute DVD that relives the

by-gone days of Windy City, can be purchased at the museum gift shop.

Visit

Coolspring Power

Museum during any of its events to see

Windy City in

operation. Our volunteer engineer will be happy to chat with you and

explain the details. For a complete list of museum functions, please

see our website: coolspringpowermuseum.org or call 814-849-6883.

See you then!

|