February 2014

Snow Part 1: The History

By Paul Harvey

The October 2013 Engine Show of the

Now, as snow covers the museum outside as well as much

of the equipment, I would like to reflect on the Snow engine in this

two part Flywheel article. In the first part, the history of

the company and the engine, as well as the people who made it happen,

will be discussed. Next month's article will feature the Coolspring

engine and how it was saved, moved to our location, and put into

operation. Much of this material has never before been published in one

work, and it is hoped that the reader will enjoy.

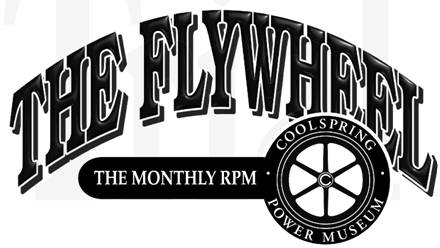

Our story unfolds in 1840 when 23 year old Henry

Rossiter Worthington becomes interested in steam boats on the

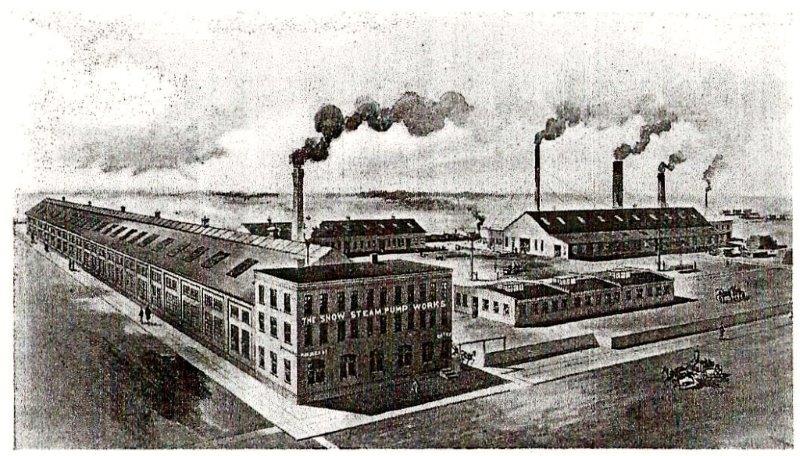

The duplex steam pump is such a wonderfully simple, yet

magnificently practical, invention. Having no rotating parts, it

consisted of two steam cylinders providing the power to two pumping

cylinders; with each power and pump piston mounted on a common piston

rod. When one cylinder acted, it triggered a steam valve that then

operated the other cylinder which then acted on a valve to again operate

the first cylinder. As the fluid discharge pressure equaled the steam

pressure, the pump simply stopped; to begin again when discharge

pressure lowered. There is a restored

Over the ensuing years, the steam pump business

flourished as they were adapted to many uses. Municipal water works

found these pumps very dependable and they were made in huge sizes to

meet the demand. Many persons entered the steam pump business. In

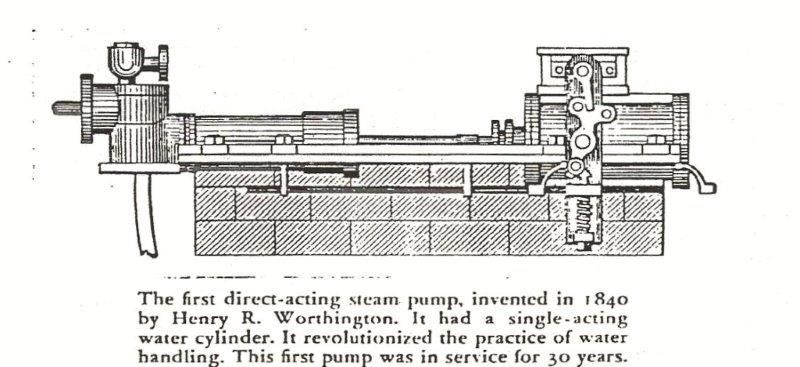

1889, we find James H. Snow and Daniel O'Day, former employees of

National Transit Company of

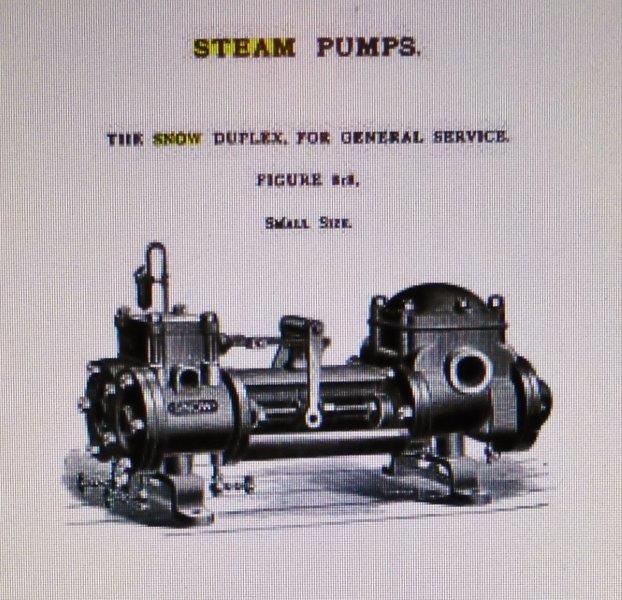

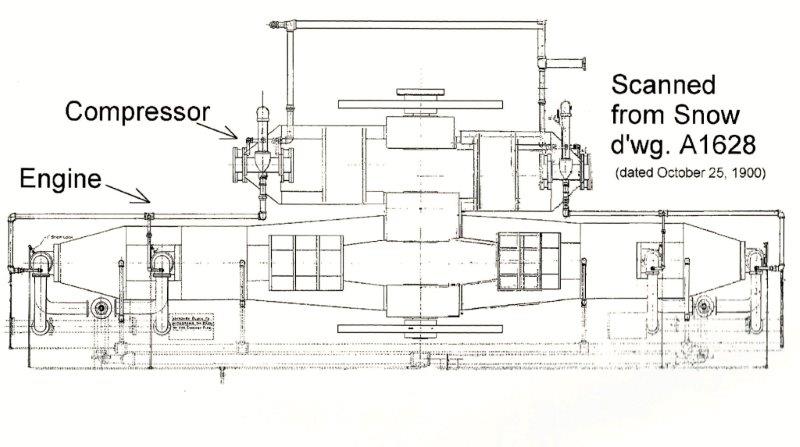

With the dawn of the twentieth century approaching, the days of the huge steam pumps were in decline. Soon they would give way to the new technology, the internal combustion engine. Snow realized this and hired John Klein, Chief Engineer for National Transit Company, as his Consulting Engineer. Since Snow was a former National Transit employee, these two men most likely were friends. However, it does seem odd that Klein would design a new engine for his own firm's competition! No explanation has been found for this.

So the first four engine compressor units built by the

Snow Steam Pump Works in

After the completion of these engines, Snow branched off

into its own design of tandem cylinder engines as seen in the Coolspring

engine. Their catalog of 1914 simply states that further engines were,

"of their (Snow's) own design". The firm had wisely listened to the

suggestions of the operators of the big natural gas companies throughout

the

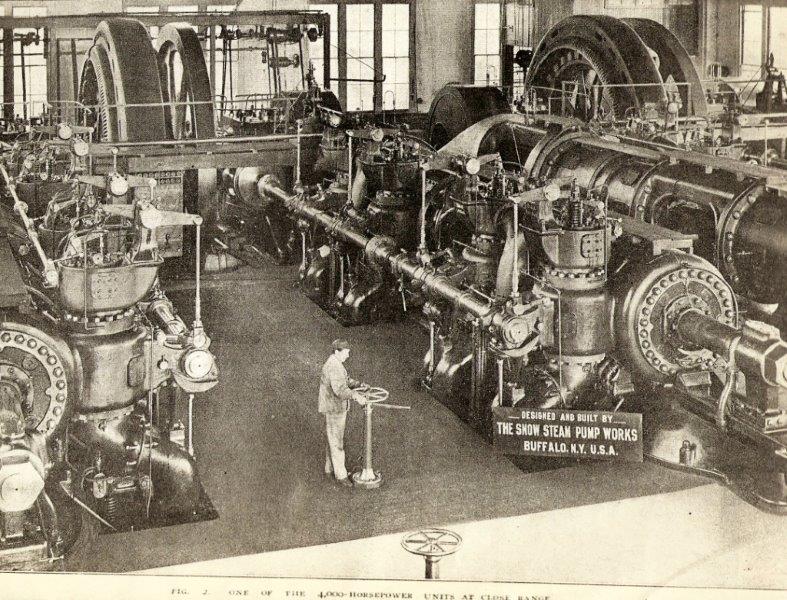

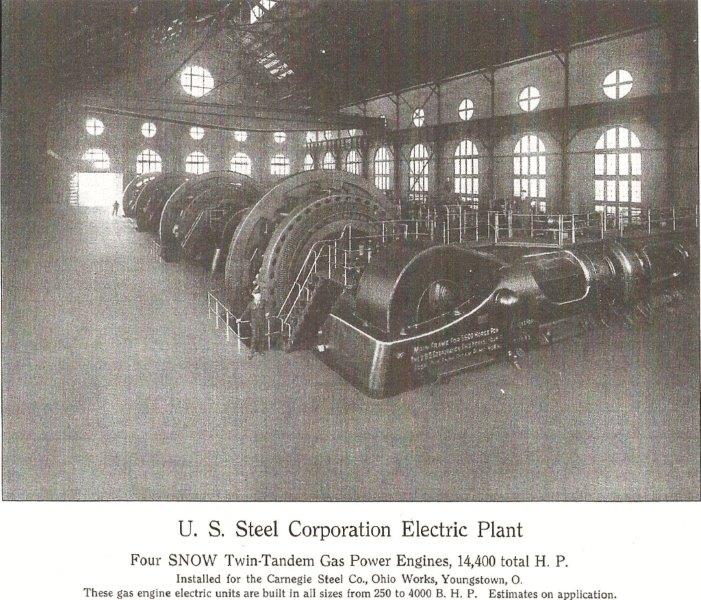

Very early, Snow was building some of the largest gas

engines known. Photo 6 shows a 4,000 hp Type A design

with an integral electric generator beside the flywheel. This engine

had a 42 inch bore and 60 inch stroke with a unique valve mechanism.

Note the size of the operator in the center of the photo! It was

guaranteed to have a 33% non-continuous overload capacity. Photo

8 shows some other large electric generating engines at the

Carnegie Steel Works in

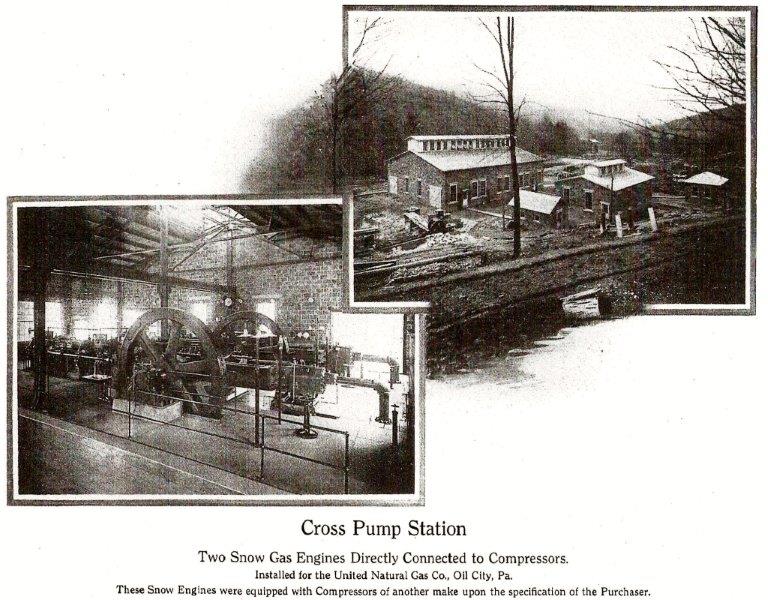

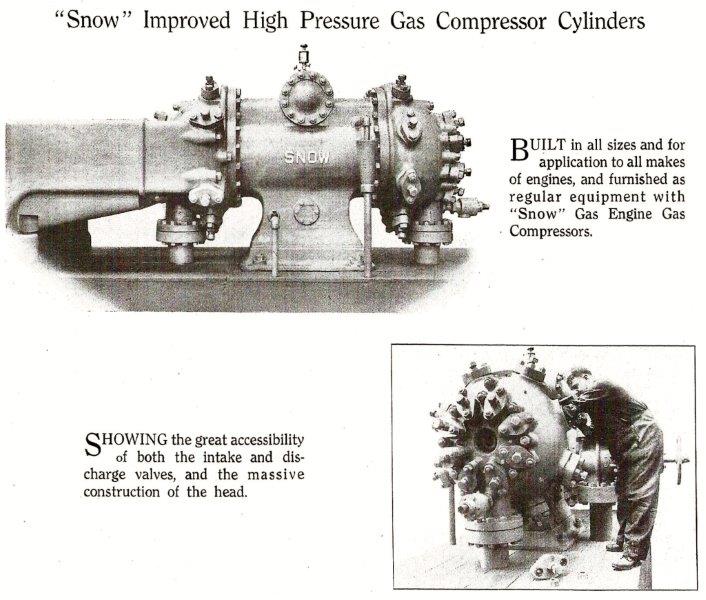

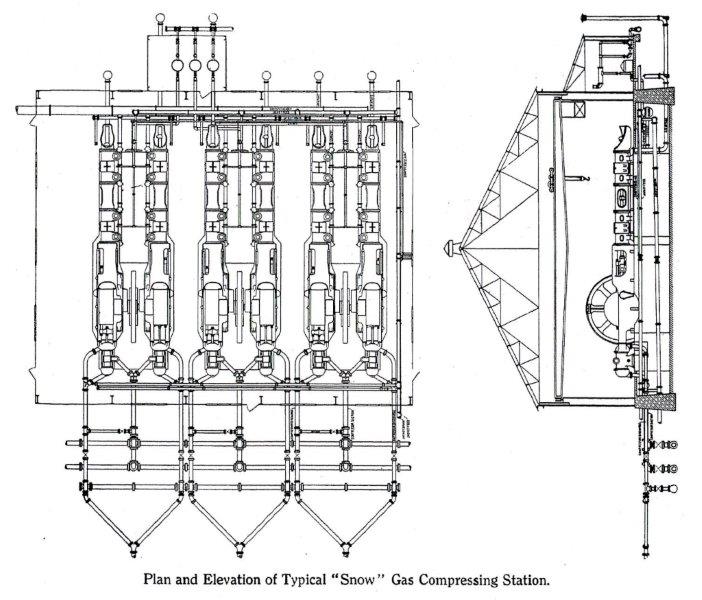

The entire power end of the Snow engine, which consists of two double-acting cylinders (fires on both sides of the piston) placed in tandem (one in front of the other) operates the gas compressor located behind the crankshaft. Snow would supply compressors from other manufacturers if specified by the buyer, but preferred to use their own as shown in Photo 9. This compressor was also double-acting and had a power stroke from the engine for every stroke it traveled. This design was very efficient to have the engine and compressor made into one unit. Photo 10 shows the layout of the complete station with the interconnections of pipes joining the multiple units.

Birdsill Holly was an inventor from

Then came the great merger. Probably caused by the

panic of 1899, Charles C. Worthington, always aggressive and wealthy,

saw his opportunity to expand and formed the International Steam Pump

Company that included many firms now finding themselves in financial

duress. The new company included the Snow Steam Pump Works, the Holly

Manufacturing Company, the Clayton Air Compressor Works, Blake and

Knowles Steam Pump Works, the Deane Team Pump Company,

Laidlaw-Dunn-Gordon Company, and the Power and Mining Machinery

Company. This accounts for the name, "International Steam Pump Company"

on the nameplate of some of the engines at Heath Station. All

production was integrated into the Snow Works at

Following the merger, both Snow and Deane continued to

flourish under the

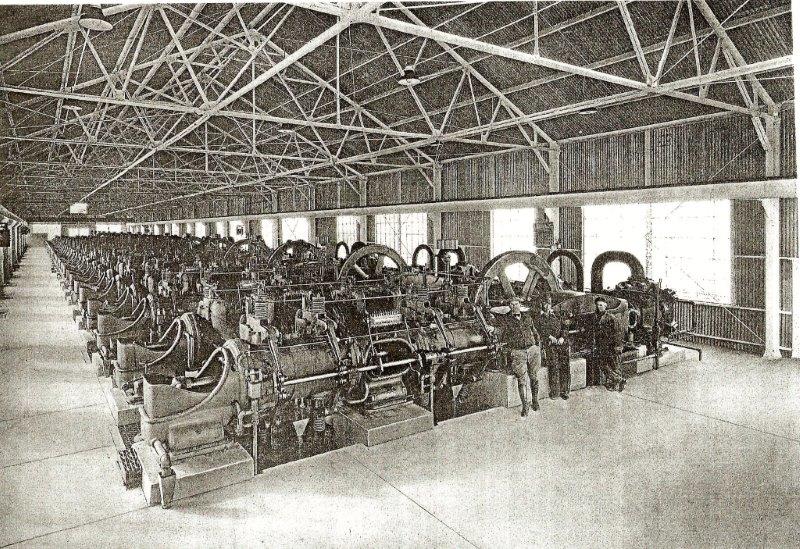

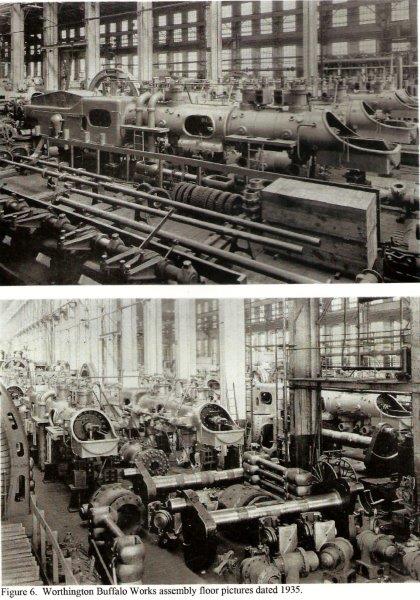

Photo 12 depicts a very busy erecting

floor at the Buffalo Works in 1935. The building appears to be huge

with many engines in various stages of completion. All these grand

machines had to be assembled, test run, then taken apart again to be

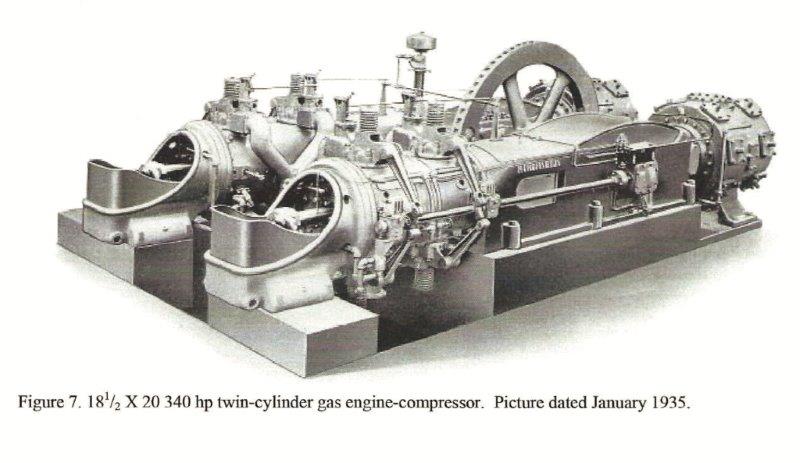

shipped to their final locations. Also new, circa 1935, was a smaller

engine not using the tandem cylinder configuration that had been the

standard of the firm. As seen in Photo 13, this unit had

twin, double-acting power cylinders and opposed compressors. Note the

outboard sideshafts that made a more space saving design. An engine

like this operates at the Western Minnesota Steam Threshers Reunion in

Gradually the demand for these huge engines declined but

I wish to give special credit and thanks to two

individuals whose untiring research made this brief work possible.

It is my desire to incorporate this work, and the upcoming second part,

into one comprehensive booklet sometime in the future.

Loree A. D. Paulson, PE: He was the last president

of Worthington Compressors in

Thomas "Mac" Sine, ME: He is Senior Analytical

Engineer with his primary function being Gas Engine Engineering.

He has completed 25 years of service with Dresser-Rand in Painted Post,

NY.

Please come to Coolspring for our June 2014 Expo and watch the Snow run. It will be held June 19, 20, and 21, 2014. See you then!

Photo 1: Drawing of the Worthington steam pump

Photo 2: Snow Steam Pump Works of Buffalo, NY

Photo 3: Snow duplex steam pump

Photo 4: A Klein-Snow engine compressor unit

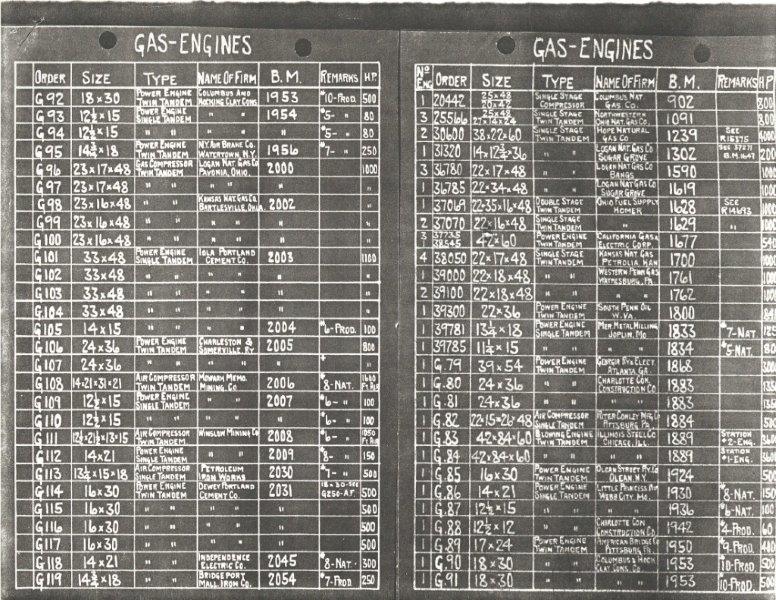

Photo 5: A page from early Snow records

Photo 6: 4,000 hp Type A Snow engine and generator

Photo 7: Cross (later Heath) Station under construction ca.1914

Photo 8: Snow electric generating engines at

the Carnegie Steel Works in

Photo 9: Snow compressor

Photo 10: Snow compressor plant

Photo 11: 1920s era Worthington engine

Photo 12: Production floor at the Buffalo Works ca.1935

Photo 13: Worthington engine of 1935

Photo 14: Snow name plate