June 2013

It's Alive!

By Paul Harvey

When this article rolls off the presses, our big June Show is less than two weeks away. That's right; June 13, 14, and 15 will be our June Expo featuring oil engines. The museum exhibits will be running, the fields will be full of exhibitors, there will be an enlarged flea market, and plenty of good food. But most important, the fellowship of chatting with old friends and making new ones, as one enjoys the long warm days of Summer and the sounds of engine exhaust.

We already have the April and May open weekends under

our belts. They were quite successful with many people attending. Now,

every weekend is a work weekend as we prepare for the June Expo. Yes,

the museum is now ALIVE! There never seems to be enough time to

prepare, but when it happens, all falls together and a great event is

enjoyed.

For a change of pace, I have decided to take the reader "behind the scenes" and show just a few of the projects that our volunteers do to get ready. As one can imagine, there are so many more jobs being done than the ones included here, and each project has its coordinator who works hard to improve the overall function of his project as well as that of the museum. See the photos and enjoy!

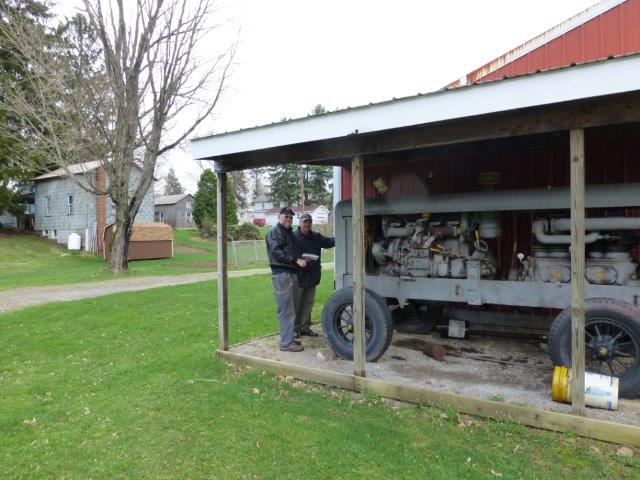

Photo 1 shows Dave and Buck on a cold

April day planning a radiator change for our main air compressor. This

unit was assembled in

Photo 2 shows Rob constructing a new

workbench in the

Photo 3 shows Reid cleaning the 300 hp

Miller Improved gas engine. This large engine runs on a posted schedule

during the shows and is always a crowd pleaser. The compressed air

start up sequence is the most impressive. After the October show is

over, the engines are given a heavy coat of grease to prevent rusting

and this has to removed again in the spring. Reid, one of the engineers

operating this engine, will soon have it shiny again. This engine was

built in 1913 in

Photo 4 shows a new addition in our

wooded oil field display area. Here, one will find many small buildings

with individual displays depicting the various technologies of pumping

and transporting crude oil in the early 1900s. Stewart is erecting a

vintage power house moved from the Pleasantville, PA area. It contains

a 15 hp two-cycle Pattin Brothers engine built in

Photo 5 shows Tom and Rod digging the foundation hole for a

steam engine to be operated from the

Photo 6 shows Dylan oiling and operating

the 1880s Farrar and Trefts steam engine from the

Photo 7 shows making the 30 feet long

legs that will support the water tank that will provide cooling water

for the 600 hp Snow, as well as the Friend's Exhibition Hall, Pat's

Place, and other installations being developed on the hill. Already

three 1,000 gallon concrete tanks have been buried that will collect the

water to be pumped overhead for reuse. The top of the tank will be over

40 feet and easily seen from the highway, marking the museum's location

to all travelers. Photo 8 shows Ben, Chris and Doug

placing one of the legs with the museum's

Mowing the 25 acres of the museum fields and parking

areas is a never ending task. Photo 9 shows Kevin

with his Kubota and 10 foot wide Woods mower making short work of the

project. He keeps his equipment on the grounds here and drives

from

Photo 10 shows Tom working on the museum cooling water system near the Fred Merry Pump House. Tom manages to start in April to service all the pumps needed to keep cooling water flowing to the engines during our events. The water is pumped from the creek but no water is returned to it due to environmental concerns. It is stored in several large tanks and piped to many of the original buildings to provide engine cooling. It then returns to a large concrete underground sump tank. From there, it is pumped uphill by the several pumps in the Pump House, through a radiator type cooler, to the storage tanks on higher ground. Downhill flow through all the engine water jackets is by gravity so that damaging excessive pressure can not be applied. Hence, all our cooling water is recirculated and not wasted on the ground. It is a huge system with many valves and pumps to check and maintain in order to have the necessary cooling water for our engines.

Photo 11 shows the balcony addition to the Friend's Exhibition Hall. Some static displays have been placed there and are easily viewed from the ground level. This has given room for the building's work area just underneath. Mike is seen operating the forklift with Mark on the balcony to guide the engine into place. Kevin is in the background supervising the move.

Photo 12 is the 50 hp White and Middleton gas engine

arriving at the museum and being unloaded in Pat's Place which will be

its permanent home. Mike and Dave are busy at work to place the

engine. This monumental machine, with its 7 1/2 foot diameter flywheels,

was removed from the Buckeye Pipe Line Company's Bremen Station in the

1960s by the late Dr. John Wilcox. There, it had pumped crude oil along

with the big Model 4 Klein located in the

Photo 13 is a new acquisition belonging to the

author. It is a 20 hp South Penn Special half breed that pumped an oil

well near Dutchman Run, WV. These were very sturdy engines built near

Probably the most unseen job to do for the museum is advertising. But

sometimes in can be fun as Photo 14 shows. I

did a radio interview with Danna and Dick Vernon for WYTM-AM 1380

Kittanning.

The

Yes,

Would you like to become a volunteer at the

museum? We always need more help with projects like these and

would like to teach you to become an engineer. We have so many

machines that need adopted and operated for our events. Please

contact any of our members for more information.

Looking ahead, July 20 and 21 will be our open weekend and July 20 will be our second annual History Day with its Car, Truck & Tractor show. Please call 814-849-6883 for more information. Just drive in with your antique car or truck and join us for an event without the large crowds so that our engineers can chat with you and answer all your questions. See you then!

Photo 1: Dave and Buck planning a radiator change

Photo 2: Rob constructing a new workbench

Photo 3: Reid cleaning the 300 hp Miller Improved gas engine

Photo 4: Stewart is erecting a vintage power house

Photo 5: Tom and Rod digging the foundation hole for a steam engine

Photo 6: Dylan oiling and operating the 1880s Farrar and Trefts steam engine

Photo 7: making the 30 feet long legs that will support the water tank

Photo 8: Ben, Chris and Doug placing one of the

legs with the museum's

Photo 9: Kevin with his Kubota and 10 foot wide Woods mower

Photo 10: Tom working on the museum cooling water system

Photo 11: The balcony addition to the Friend's Exhibition Hall

Photo 12: 50 hp White and Middleton gas engine arriving at the museum

Photo 13: 20 hp South Penn Special half breed engine

Photo 14: Danna and Dick Vernon of WYTM-AM 1380 Kittanning