March 2013

Coolspring Municipal Works

By Paul Harvey

Today is Groundhog Day and, amazingly, Punxsutawney Phil

did not see his shadow which means an early Spring. Wow, this is hard to

imagine as we are still in the grip of Winter with its continuing severe

cold and snow. Virtually all outside work has stopped at the museum due

to this. I guess one could say that there is too much snow to work on

the Snow! Now is when a warm shop is great and in it I am progressing

with the restoration of a 15 horsepower Pattin Brothers engine made in

Marietta, Ohio. This is a nice four-cycle engine with a pendulum hit

and miss governor. It will be running at the June Show. It is also a

good time to do writing and I am taking advantage of that to finally

complete the Bores & Strokes edition of the engines built

in Butler, PA.

Searching for a topic to meet my February deadline for

this issue, I realized that I have not featured a museum building and

its equipment in well over a year. Since all its engines are now

running, I have chosen the Coolspring Municipal Works for our March

Flywheel. The following will be a tour of that building.

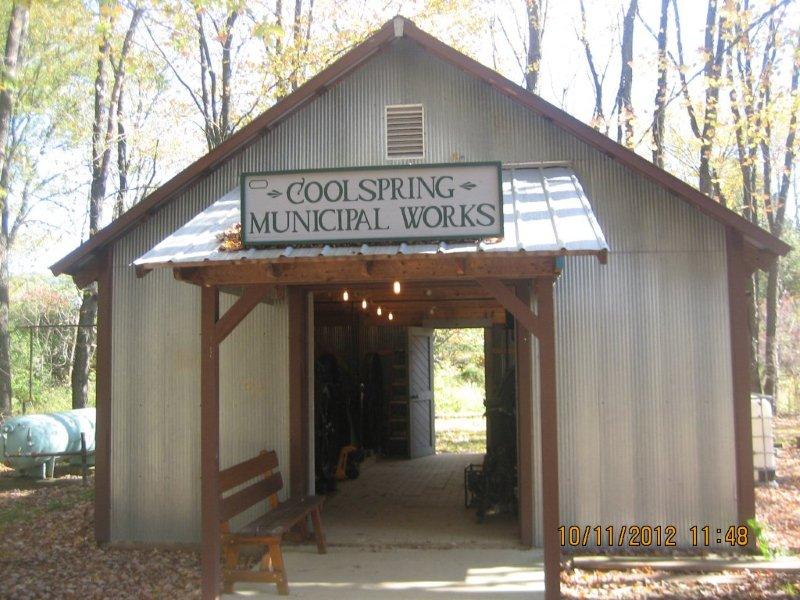

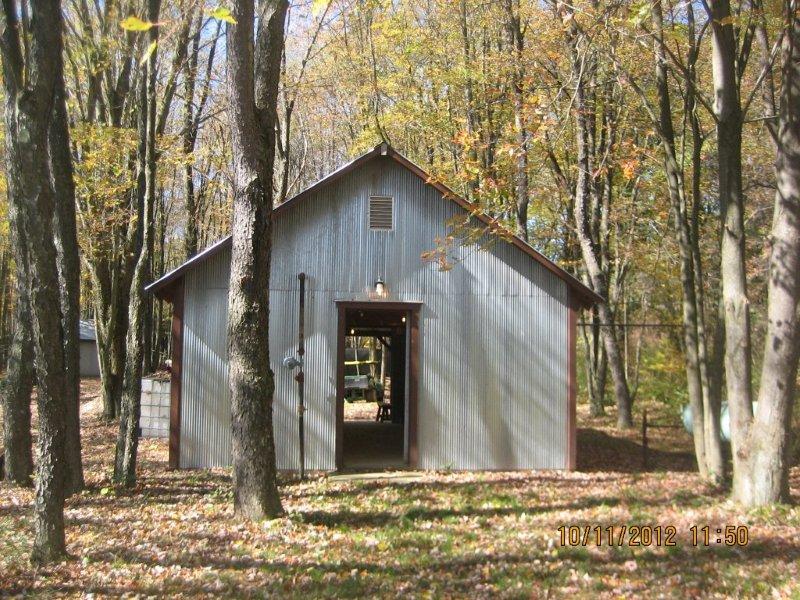

This structure was built in 2002 but took a long time to finally complete. Photo 1 shows the front entrance. It is located in a wooded area and is equipped to represent a power house that could have served a large estate or a small rural village in the early 1900s. It can provide the water pumping, the electricity, the compressed air and the telephone service that might have been required. It is equipped with the old knob and tube style wiring and period lighting and can provide its own direct current to illuminate these. We will now take a look inside.

Photo 2 shows the water pumping equipment. It is a 3 1/2 horsepower vertical Otto gasoline engine that was made in Philadelphia, PA direct connected by means of a clutch to the water pump. This pump is a vertical Deane triplex that was made in Holyoke, MA. It originally served a large summer estate on Deer Isle, Maine. It pumped the water from wells or a lake to a large elevated tank and gravity fed the water to the estate or village, much like today's systems. During the daytime, the engineer would be present to keep all running well, and at night that tank would supply the water.

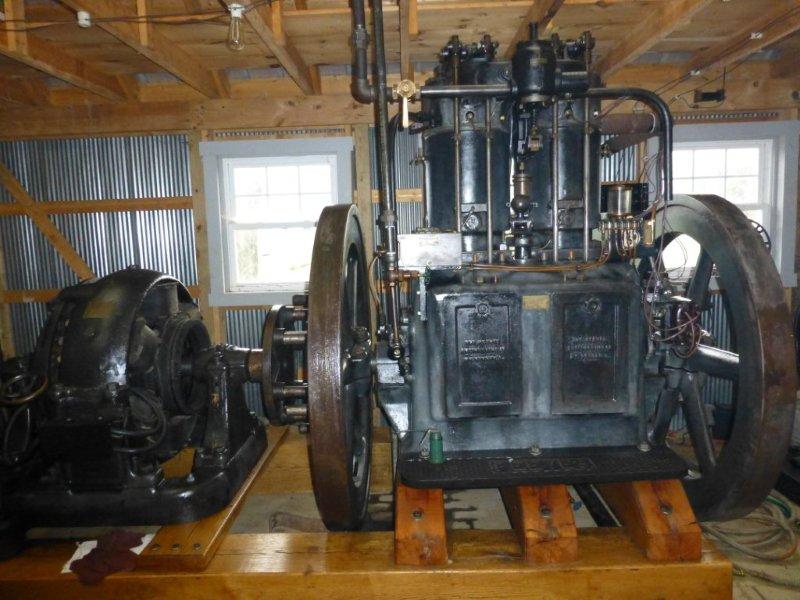

In the early 1900s there was a limited supply of electricity and most homes had only 6 or 8 light bulbs and no appliances. In rural settings direct current (DC) was common but obsolete today with the commercial alternating current (AC). Photo 3 shows the main electric supply for our Municipal Works, a 35 horsepower twin-cylinder vertical Reeves engine, made in Mount Vernon, Ohio direct connected to a DC dynamo. This unit spent its lifetime in the basement of the Dorsey Theater in Johnstown, Ohio providing direct current to operate the carbon arc movie projectors. However, it could have brightly lit a country estate and provided some lighting to 12 to 15 homes in a small village. Often, these units were shut down about midnight, making the village rely on kerosene lamps until morning.

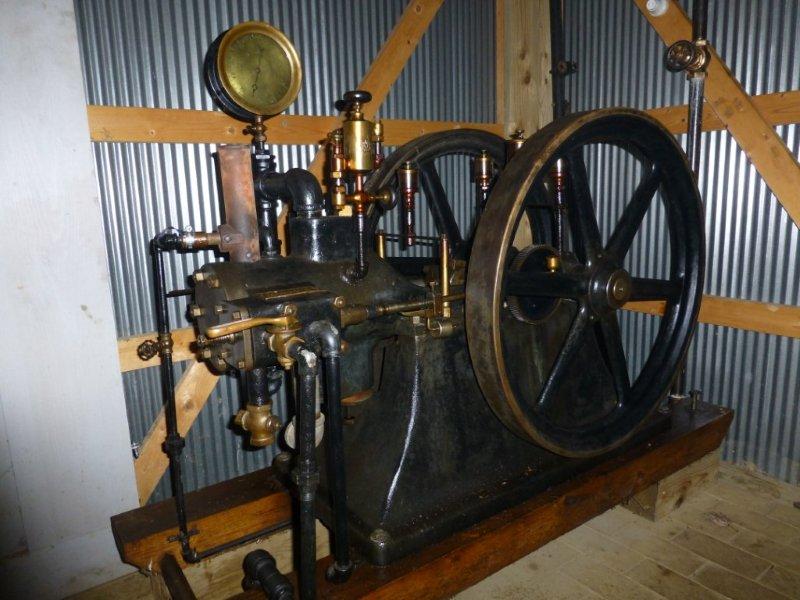

Photo 4 shows a small Flickinger combination engine and air compressor made in Bradford, PA by the Flickinger Iron Works. Originally, it was installed in a power house south of Bradford where in made compressed air to start a large compressor for oil field use. Here it has the same task of providing compressed air to start the Reeves. It also provides air for any other tasks at the Municipal Works and pressurizes a large storage tank. These were once common units to provide starting air and many different models were built.

During the daytime when the big Reeves and dynamo are not running, the Municipal Works still might need lights or electricity for some other use. Most plants had a small engine and generator installed for this use. Photo 5 shows our four horsepower Fairbanks Morse model T engine directed coupled to a three KW direct current dynamo. No prior history is available on this unit as it came from another collector. It nicely lights the Municipal Works with some power to spare. The engine is gasoline and throttle governed. It has one large electric lighting flywheel on the outside and a smaller wheel between the engine and dynamo to fit into the base casting. These units were once common on farms and country homes.

The Fairbanks Morse's electricity is controlled by the

panel board shown in Photo 6. The panel is heavy slate,

one inch thick, and contains a voltmeter and ammeter as well as a

rheostat for setting the voltage. The rheostat varies the field voltage

of the dynamo which in turn controls the output voltage. Also,

there are knife switches for control, and a small light above. We

usually run at about 100 volts of direct current electricity to give the

light bulbs ambience. The small panel to the upper left is a

double pole, double throw switch in case the building needs commercial

power.

Rural telephone service in the early 1900s usually depended on small local companies using the old wall mounted, had cranked phones. Their central station depended on a large bank of lead-acid batteries that needed recharged every day. The 11 horsepower, electric lighting White and Middleton gas engine, was commonly used for this service in New England and the eastern seaboard. Our engine, see Photo 7, was built in Baltimore, MD circa 1894, and used in a small New Hampshire telephone company. White and Middletons of all sizes were used depending on the number of batteries to be charged. Note the large, crowned face flywheels for driving the belt to the dynamo.

Photo 8 shows the 32 volt direct current dynamo that our engine operated. The huge brush holders and large wires show that it made high amperage and a low voltage needed to charge the huge bank of batteries. The engineer would operate the engine during his day shift and the batteries would maintain the system during the nights.

This concludes our photo tour of Coolspring Municipal Works and how a small rural power house might be set up. Photo 9 shows the back door and the wooded location. I think that you will enjoy a visit to the Municipal Works to sit on the bench under the porch at the front entrance and take in the ambience of a time long gone by. Plan a visit!

Coolspring Power Museum will open for its 2013 season on

April 20 & 21. A limited number of engines will be running since

the cooling water system is not filled until May to avoid possible

freezing weather. Our big June Expo will feature Oil Engines which

includes any engine with compression ignition. There will be an

amazing variety! It will be held June 13, 14, and 15.

History Day and Truck Show will be July 20. Please call

814-849-6883 for more information. It should be a great year!

Photo 1: The front entrance of Coolspring Municipal Works

Photo 2: Water pumping equipment

Photo 3: The main electric supply

Photo 4: Flickinger compressor engine

Photo 5: Fairbanks Morse engine and DC dynamo

Photo 6: Electric panel board for the Fairbanks Morse

Photo 7: White and Middleton gas engine

Photo 8: 32 volt DC dynamo for telephone service

Photo 9: The back door of Coolspring Municipal Works