July 2012

The Powers of Coolspring

By Paul Harvey

Once in a while, I find that it is difficult to choose a topic for the monthly Flywheel. Due to my copy deadline, I am writing this before the June Show but the reader is now seeing it about two weeks after the show. It would have been ideal to have the July issue feature the show report but now that will have to wait until August. However, inspiration did happen for this article at breakfast the other day when a friend suggested featuring the collection of oil pumping powers that the museum has accumulated over the past years. Wow! That sounded good and that is how "The Powers of Coolspring" article was born.

By now, the reader is probably wondering what a pumping power is and so I will offer an explanation. That is an oil field term given to the heavy, cast iron, gear driven device that actually transformed the rotary motion of the engine into the reciprocating motion used to operate the long strings of iron rods that extended outward from the central power house to operate the individual pump jacks on each oil well. The power was belt driven by a gas engine and all housed in a special building; the power house. The advantage was that many oil wells could be pumped with one central engine and power and operated by one pumper. Before this invention, each individual well required its own engine and pumping apparatus and a person to operate each. So the central power system provided convenience as well as economy to the operation of oil wells.

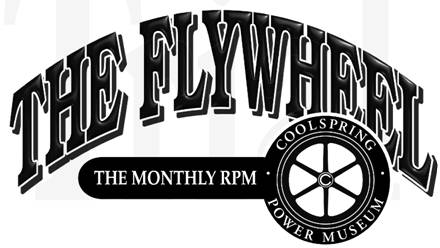

The central power house system can be seen in Photo 1 which is a cutaway view of the Lockwood Power near Clarendon, PA. This was built in 1909 and its remnants still stand today. One can see the gas engine in the left hand portion of the photo driving a belt to the pumping power. The connecting portion was known as the belt hall and was frequently used for storage as well as keeping the weather off the drive belt. The pumping power, which is seen in detail on top right of the diagram and also seen in the octagonal portion of the building, provided a bevel gear reduction to a large vertical shaft. On its very top is an eccentric mounted disc to which the individual rod lines were attached. These rods extended various distances from the power to pump each well. Some rod lines extended one half mile to distant wells and by various devices they could be made to turn corners, go up and down hills, and even cross a road. The ingenuity of the oil patch never seemed to end! The Lockwood was a very elaborate and well built installation capable of running 24 hours a day, but many power houses were merely roughly built, shed roofed structures designed only to keep some weather off the equipment and turn a quick profit.

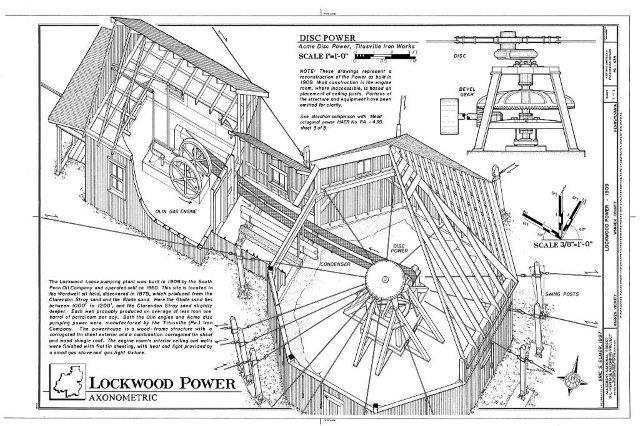

It has been said that necessity is the mother of invention and this was indeed true with the pumping power. George Allen was a successful carriage and wagon manufacturer in Winchester, MA who left his business and followed the oil fever to Franklin, PA in 1865. He embarked into the mercantile business and became very successful but also held large interests in the Galloway and Point oil fields operating many wells. However, his wells slowly declined and in the Summer of 1884 a disastrous fire destroyed them all. Aware that the decreased production would not support rebuilding each with an engine and derrick, he set to devise a means to pump many wells with one central installation that would be both cheap and effective. On March 17, 1885, he obtained patent number 313,907 for a very successful device. This can be seen in Photo 2. Eventually, three different firms, George Maloney, Oil Well Supply, and Producer's Supply built this unit and some survive today. Thus, the pumping power was born! Soon, many other firms, large and small, were building their own units and the technology spread widely throughout the entire oil field area, both in PA and nationally. The designs and variations were endless and some types located at the museum will be shown.

Shown in Photo 3 is a large and graceful power built by Producer's Supply of Franklin, PA. One can see the pulley on the right side that was turned by the flat belt from an engine. The central portion shows the large bevel drive gearing to the vertical shaft which drives the eccentric discs on top. Thus the rods are given a back and forth motion and each one will operate a pump jack on a well. This unit was located in Western PA and operated about 20 wells. But not all had to be pumped at once; each one could be hooked onto the eccentric to pump as much or as little as the operator wished. And to do all this, only one engine had to be used which provided convenience and economy.

Photo 4 is a Big Paova power which was an early offering of Oil Well Supply in Oil City, PA. Research reveals that the name, PAOVA, is taken from PA, O-hio, and west VA which were the areas that it was most used. It is a compact and lighter built power that was especially well adapted to the shallow wells common in these three states. This one was located on a hillside overlooking the Allegheny River near Hunter Station, PA. It is of note that both the power and the engine were mounted on large, naturally occurring rocks instead of the concrete foundations normally used. So nature provided the foundation and the oil patch provided the imagination to utilize.

Our next power is a very unusual one built by Titusville Iron Works in Titusville, PA and can be seen in Photo 5. This one is called a "bottom pull" as the bevel gearing is on top and the eccentrics are below. The advantage here is that the pull of the wells is located closer to the foundation and hence the iron framework does not have to be as massive. Also the gearing is most unusual as it is not only bevel but herringbone meaning that each tooth looks like a "V" instead of straight. These gears which have meshed well for years had the teeth cast in and not machined into them. The angles used to produce herringbone bevel gears are exceptionally complicated. A true marvel to forgotten pattern making and casting techniques.

Bessemer Gas Engine Company of Grove City, PA developed into a very large manufacturer of gas engine and oil field equipment by the early 1900s. Photo 6 shows their very successful Roller Power. The large bevel gear was supported by four rollers running in oil baths and aligned on the top by two rollers. This technique took the strain off the actual gearing and provided easy alignment and adjustment. They were compact and light in design but proved to be very durable. A few are still in operation today.

Photo 7 is a unique power built by Clark and Norton of Wellsville, NY. Its circular base gives it a very compact and pleasing appearance and it employs some of the designs of the Roller Power featuring rollers with gear teeth as well to improve alignment. It is the only one known and was used in the Butler, PA oil field. It appears to have survived years of use with minimal wear.

Next, in Photo 8, we see the Fairchilds-Betts power built in Warren, PA. This little unit is double geared with a set of spur gear reduction before the bevel gearing. Doing so, a smaller "big" bevel gear could be used and still develop the same amount of reduction of speed. This one is part of the museum's rod line pumping power display and actually operates two pump jacks. It is driven by a 15 hp Reid engine in the background and the two rod lines can be seen extending from the eccentric disc. The rod lines go back and forth operating the jacks up and down to simulate actual pumping. One jack is close to the unit to complete the picture and the other is about 100 yards away.

Photo 9 shows the distant pump jack operated by the Fairchilds-Betts power and Reid engine. These jacks are commonly known as "Oklahoma Style" pump jacks but were widely used throughout the Pennsylvania oil field and are the most common. They use a bell crank assembly to which the rod line can be seen attached to convert the motion to up and down to the beam which in turn pumps the well. It is very pleasant to stroll along the road with the engine noise fading in the background and watch the pump jack just squeak a bit as it moves. No one is credited to having invented the pump jack as they were actually known in ancient China where they were operated by water or animal power. Oil field ingenuity has produced many, many variations of the pump jack to fit specific uses. Some were factory made, some were homemade, and others made from casting kits that the user supplied the pipe and flat iron to assemble. Almost all the jacks at the museum are just a bit different from each other!

Some companies decided that it would be economical to combine the engine and pumping power into one unit. This could provide a smaller building and eliminate the bothersome belt. Pattin Brothers of Marietta, Ohio was one such maker and Photo 10 shows their 8 hp combination unit which is displayed here. These units were made in various configurations from several different makers but never achieved the popularity that the separate belt drive units did. Most of the more successful ones were made in smaller sizes and for fewer wells. Probably, to pump as much as a belt drive unit, the machine would just have been too large.

Finally, in Photo 11, we see a home made pumping power. This one has two sets of spur gearing to operate two cranks that would have extended to a well in each direction hence balancing the load. The gearing does not really match and it is mounted on a steel frame but evidence shows that it had plenty of use. Most probably, a small engine was mounted on the left part of the frame. Home mades were common in all the old oil fields and used primarily on wells of low production. They served well and could be built from the scrap pile so provided economy. Many have been noted in the shallow wells on the Knox, Emlenton, and East Brady, PA fields. They certainly served their purpose and cannot be forgotten.

Hopefully, the reader has enjoyed this introduction to the pumping power and pump jacks. It is a fascinating history that is not well documented and there is still so much to discover. Please consider attending one of our events to see this collection as well as the entire museum. Although the June show is now over, there is much more to come! Our open weekends will be July 21 and 22, August 18 and 19 and September 15 and 16. Then the big and final Expo and Swap Meet will be October 18, 19 and 20, 2012. July 21 will be our special History Day with personal tours and luncheon by advance ticket sale. Call 814-849-6883 for reservations. All other visitors will be welcome also but must donate admission and buy lunch if they wish. We are also starting an annual Car and Truck Show on July 21 and free admission to all who bring an antique or classic vehicle. For information about the Car and Truck Show, please call 814-379-9813 between 6 pm and 9 pm. Hope you can attend one of our events and see some big engines run! See you then!

Photo 1: Lockwood Power near Clarendon, PA

Photo 2: George Allen's pumping power

Photo 3: Producer's Supply pumping power

Photo 4: Big Paova pumping power

Photo 5: Titusville Iron Works pumping power

Photo 6: Bessemer Roller pumping power

Photo 7: Clark and Norton pumping power

Photo 8: Fairchilds-Betts pumping power

Photo 9: "Oklahoma Style" pump jack

Photo 10: Pattin Brothers engine and pumping power

Photo 11: "Home Made" pumping power